Datex-Ohmeda S/5 Compact Anesthesia and Compact Critical Care Monitors

56

Document no. M1144955-001

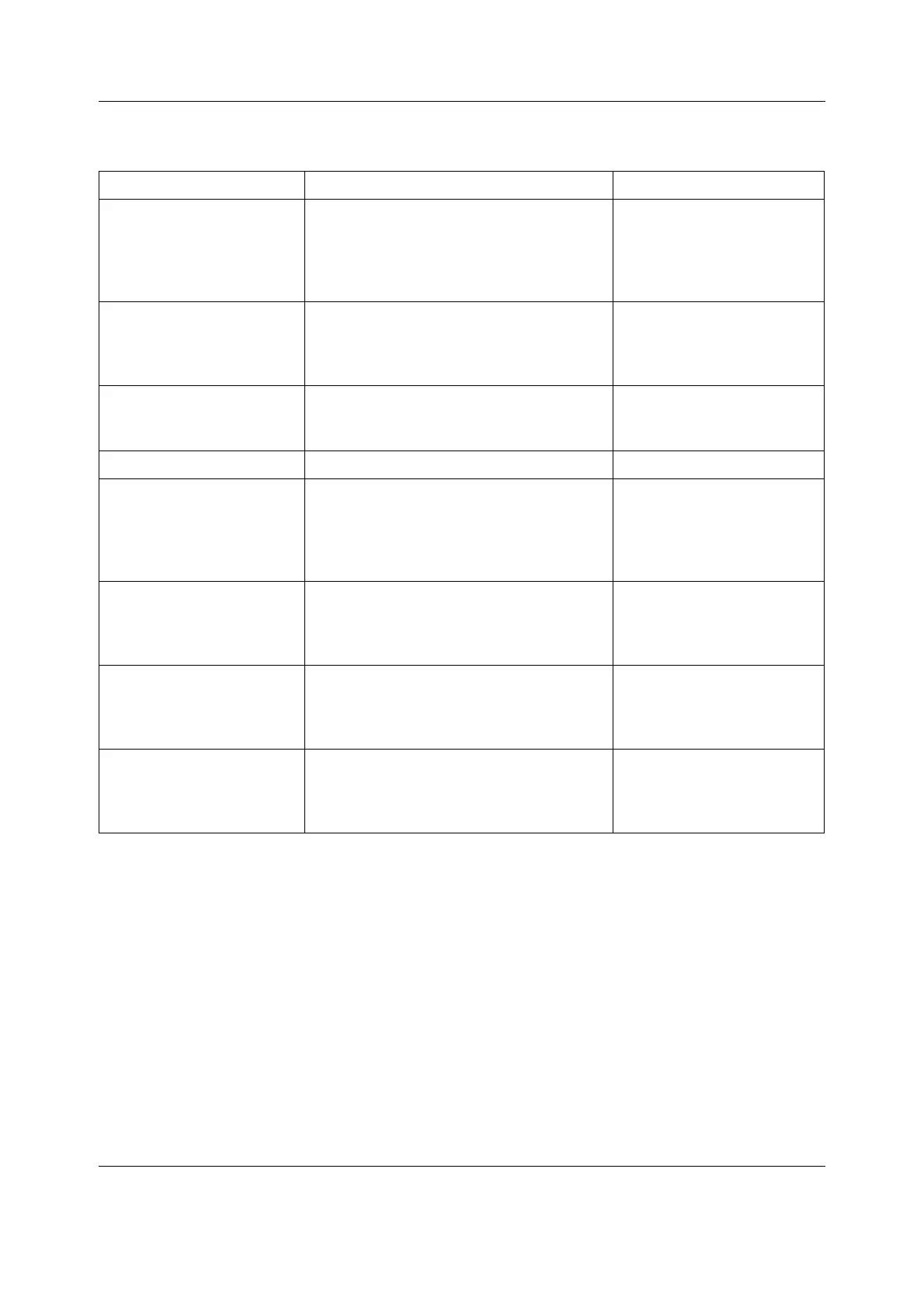

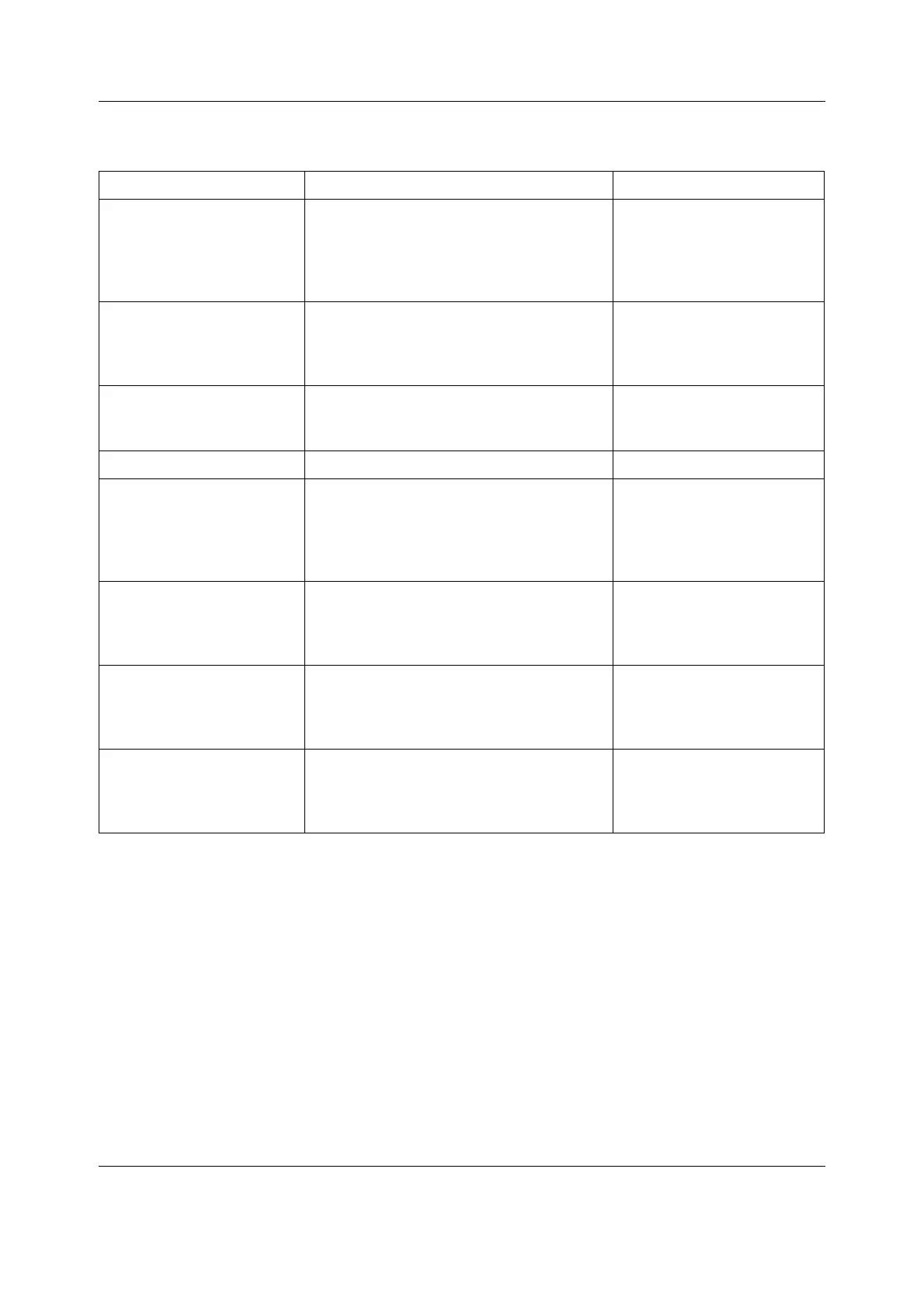

Table 8 Description of system test

Test label Description If test fails

Pump unit function Stepper motor aspirates/pushes room air

through the zeroing valve. If the stepper is

working properly, it is able to generate small

negative/positive pressure at the pump unit

pressure sensor.

Check the function of stepper

motor.

Cath press = pump press Pump pressure sensor and catheter pressure

sensor readings are compared at three

pressures: at ambient pressure, at approx.

+100 mbar and –100 mbar.

Calibrate the pressure sensors.

Tubing leak test The air tightness of the module inner tubing

from the zeroing valve to the pump valve is

tested.

Check tubing and connections

for leaks.

Pump unit leak test The air tightness of the pump unit is tested. Check pump unit for leaks.

Cath conn. leak test The air tightness of the zeroing unit and

catheter connector is tested.

Make sure that the catheter

connector is properly closed

during the test. Check the

zeroing unit and the catheter

connector for leaks.

Block test Air is aspirated through the zeroing valve. If

pressure at the pump pressure sensor drops

too much, the tubing/valves from the zeroing

valve to the pump pressure sensor is blocked.

Check the tubing/valves for

blocks.

Zero valve function Module pneumatic system pressurized and

then the zeroing valve is opened to room air.

If the pressure does not drop, the zeroing

valve may not be functioning.

Check the function of the

zeroing valve.

Pump valve function Module pneumatic system pressurized and

then the pump valve is opened to room air. If

the pressure does not drop, the pump valve

may not be functioning.

Check the function of the

pump valve.

Loading...

Loading...