8-14 750/760 Feeder Management Relay GE Multilin

8.3 METERING 8 COMMISSIONING TESTS

8

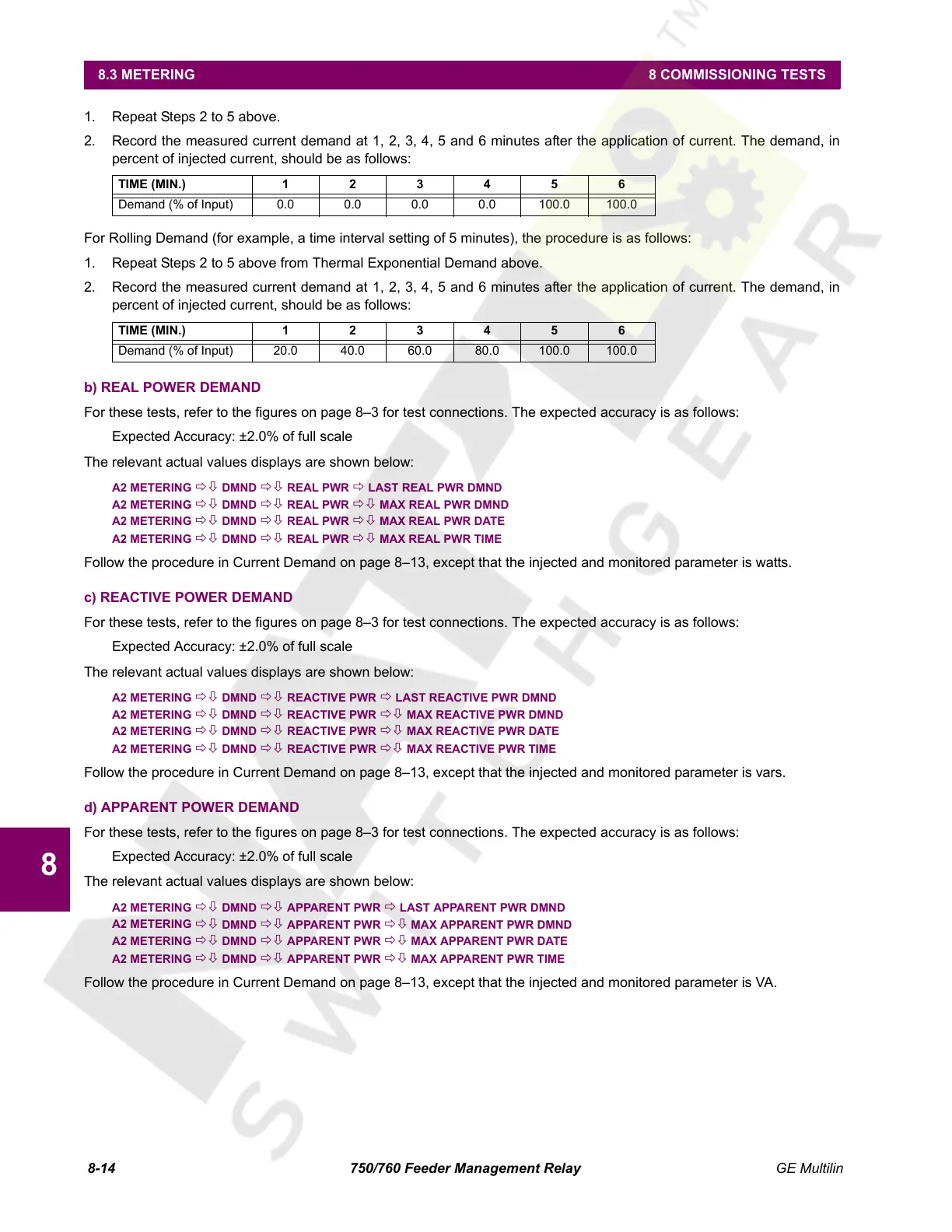

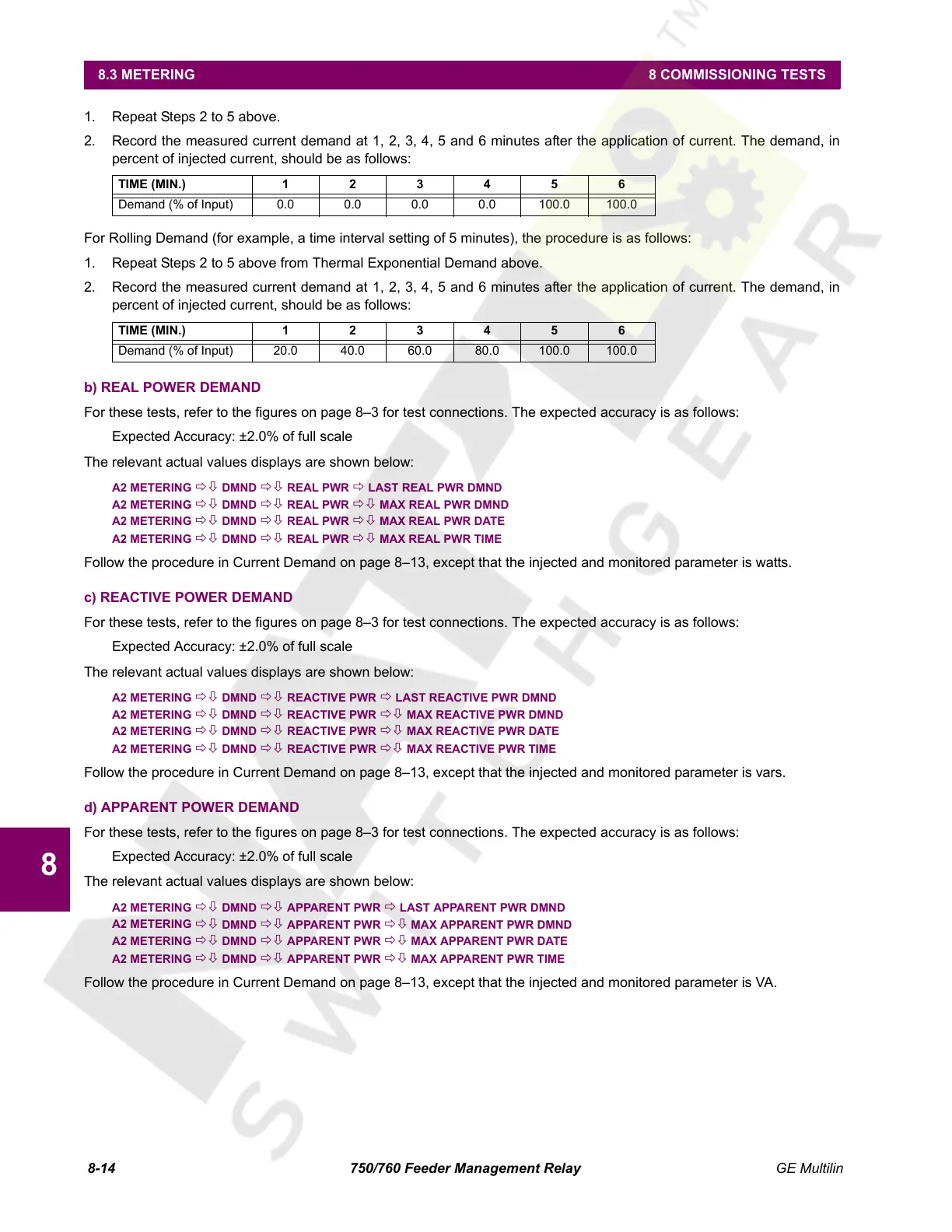

1. Repeat Steps 2 to 5 above.

2. Record the measured current demand at 1, 2, 3, 4, 5 and 6 minutes after the application of current. The demand, in

percent of injected current, should be as follows:

For Rolling Demand (for example, a time interval setting of 5 minutes), the procedure is as follows:

1. Repeat Steps 2 to 5 above from Thermal Exponential Demand above.

2. Record the measured current demand at 1, 2, 3, 4, 5 and 6 minutes after the application of current. The demand, in

percent of injected current, should be as follows:

b) REAL POWER DEMAND

For these tests, refer to the figures on page 8–3 for test connections. The expected accuracy is as follows:

Expected Accuracy: ±2.0% of full scale

The relevant actual values displays are shown below:

A2 METERING ÖØ DMND ÖØ REAL PWR Ö LAST REAL PWR DMND

A2 METERING ÖØ DMND ÖØ REAL PWR ÖØ MAX REAL PWR DMND

A2 METERING ÖØ DMND ÖØ REAL PWR ÖØ MAX REAL PWR DATE

A2 METERING ÖØ DMND ÖØ REAL PWR ÖØ MAX REAL PWR TIME

Follow the procedure in Current Demand on page 8–13, except that the injected and monitored parameter is watts.

c) REACTIVE POWER DEMAND

For these tests, refer to the figures on page 8–3 for test connections. The expected accuracy is as follows:

Expected Accuracy: ±2.0% of full scale

The relevant actual values displays are shown below:

A2 METERING ÖØ DMND ÖØ REACTIVE PWR Ö LAST REACTIVE PWR DMND

A2 METERING ÖØ DMND ÖØ REACTIVE PWR ÖØ MAX REACTIVE PWR DMND

A2 METERING ÖØ DMND ÖØ REACTIVE PWR ÖØ MAX REACTIVE PWR DATE

A2 METERING ÖØ DMND ÖØ REACTIVE PWR ÖØ MAX REACTIVE PWR TIME

Follow the procedure in Current Demand on page 8–13, except that the injected and monitored parameter is vars.

d) APPARENT POWER DEMAND

For these tests, refer to the figures on page 8–3 for test connections. The expected accuracy is as follows:

Expected Accuracy: ±2.0% of full scale

The relevant actual values displays are shown below:

A2 METERING ÖØ DMND ÖØ APPARENT PWR Ö LAST APPARENT PWR DMND

A2 METERING

ÖØ DMND ÖØ APPARENT PWR ÖØ MAX APPARENT PWR DMND

A2 METERING

ÖØ DMND ÖØ APPARENT PWR ÖØ MAX APPARENT PWR DATE

A2 METERING ÖØ DMND ÖØ APPARENT PWR ÖØ MAX APPARENT PWR TIME

Follow the procedure in Current Demand on page 8–13, except that the injected and monitored parameter is VA.

TIME (MIN.) 123456

Demand (% of Input) 0.0 0.0 0.0 0.0 100.0 100.0

TIME (MIN.) 123456

Demand (% of Input) 20.0 40.0 60.0 80.0 100.0 100.0

Courtesy of NationalSwitchgear.com

Loading...

Loading...