An active window pops up:

BACK

CH1

A

OFFSET X

CTL

EIN

+125%

–050%

INC

RES

DEC

+050%

+030%

CH3

>>

AKT

ON

B

OFFSET Y

SYM

OFF

SERVO

PHASE 1 Prog.MIX

TRIM

ON

Select

CLR

NO

LOGIC

Assign a switch or control switch as described in sec-

tion Control and Switch Assignment (page 26).

Press the BACK button at the top left of the display

to return to the mixer selection.

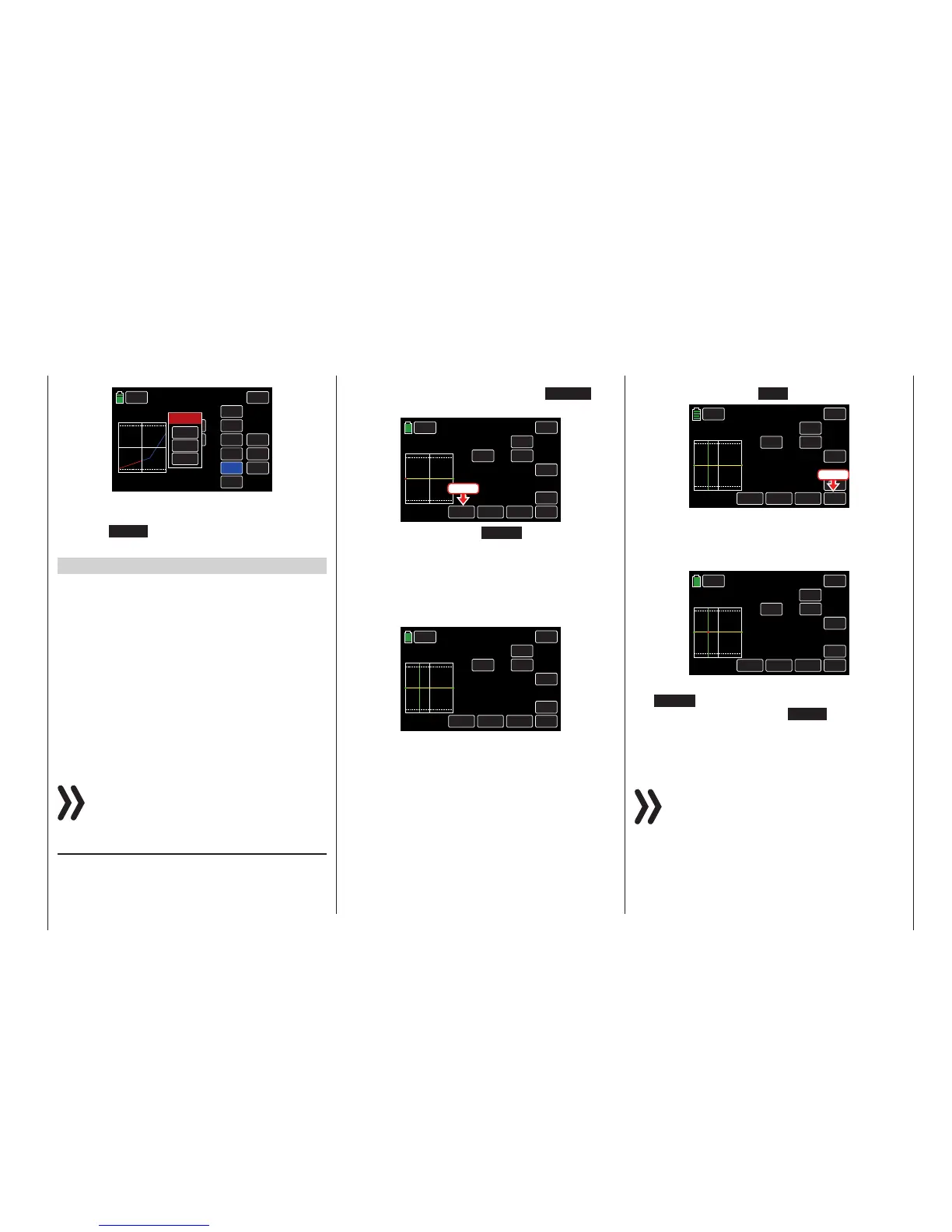

Curve (6 to 8) Mixer Setup

These three curve mixers make it possible to define

extremely nonlinear mixer guide lines with up to five

freely positionable points between the two endpoints

along the control travel: L (low = -100% control travel)

and H (high = +100% control travel) .

Programming Details

The control curve can be specified by up to 7 points,

(termed “support points”) along the entire control stick

travel. In the basic program setting, 2 support points

describe a linear characteristic; the two endpoints at

the bottom control stick stop L and at the top control

stick stop H.

Notice

The following examples are for demonstration

purposes only and do not represent a realistic

mixer guide line.

Setting Support Points

A green vertical line, normally hidden, appears and

movessynchronously in the graphic between the two

mixer input control endpoints once the control switch

is activated. (In the example below, control function

CH8 is assigned to theside proportionalrotary control

SL1.) To show the green line, press the ST OFF but-

ton at the bottom left to activate the switch:

BACK

PHASE 1

IN

OUT

POINT

ON

INC

ENT

DEC

Y-axis

X-axis

ST OFF

ACT

–100%

000%

000%

L

SERVO

Prog.MIX

ON

CTL

CH8 >> CH10

TRIM

ON

Press

The value field changes to ST ON, the green vertical

line representing the temporary control position ap-

pears in the graph and the control position is numeri-

cally displayed in the input IN line.

In the example below, the control at input CH8 is at

-045% of the control travel. The output signal remains

000% since a value has not been entered:

BACK

PHASE 1

IN

OUT

POINT

ON

INC

ENT

DEC

Y-axis

X-axis

ST ON

ACT

000%

000%

?

SERVO

Prog.MIX

ON

CTL

CH8 >> CH10

–045%

TRIM

ON

The intersection of this line with the mixer curve is

identified as output in the OUT line and can be var-

ied at the support points within a range of ± 125%.

This alters the control signal which affects the mixer

output.

Up to five additional support points can be set be-

tween the L and H endpoints; the distance between

each support points must be a minimum of 25%.

Move the green line via the related control. To set a

support point, press the ENT button:

BACK

PHASE 1

IN

OUT

POINT

ON

INC

ENT

DEC

Y-axis

X-axis

ST ON

ACT

000%

000%

?

SERVO

Prog.MIX

ON

CTL

CH8 >> CH10

–045%

TRIM

ON

Press

A red dot appears at the intersection between the two

lines. At the same time, the ? in the POINT line is re-

placed with a point number, and the value field to the

right shows the current output value:

BACK

PHASE 1

IN

OUT

POINT

ON

INC

ENT

DEC

Y-axis

X-axis

ST ON

ACT

000%

000%

1

SERVO

Prog.MIX

ON

CTL

CH8 >> CH10

–045%

TRIM

ON

The set point can be moved horizontally with

the X-axis function within a range of approximately

± 90%, and vertically with the Y-axis function within

a range of ±125%. Refer to the Changing the Sup-

port Point Value section (page 140) for additional in-

formation.

Notice

Remember that the percentages in the input (IN)

and output (OUT) line always refer to the tempo-

rary position of the control stick and not to the

position of the point.

Use the same procedure to set the other support

points. The 5 support points between the L and H

endpoints can be created in any order; support points

139

Function menu | general - Free mixer

Loading...

Loading...