Programming Example

Phase-Specific Flaps Trimming

The following example shows how to correct the

trimming of the phase-specific (and recallable) flaps

trimming through only one control element in all the

phases.

To understand this programming example make sure:

individual menu descriptions are read and under-

stood, be familiar with basic transmitter use, perform

the fixed-wing Receiver Configuration according to

the instructions (page 32), completely program the

model into the transmitter, mechanically adjust the

controls and understand the correct lateral deflec-

tion of all rudders. It helps, but does not hinder, if the

model has already performed test flights and received

the resulting adjustments.

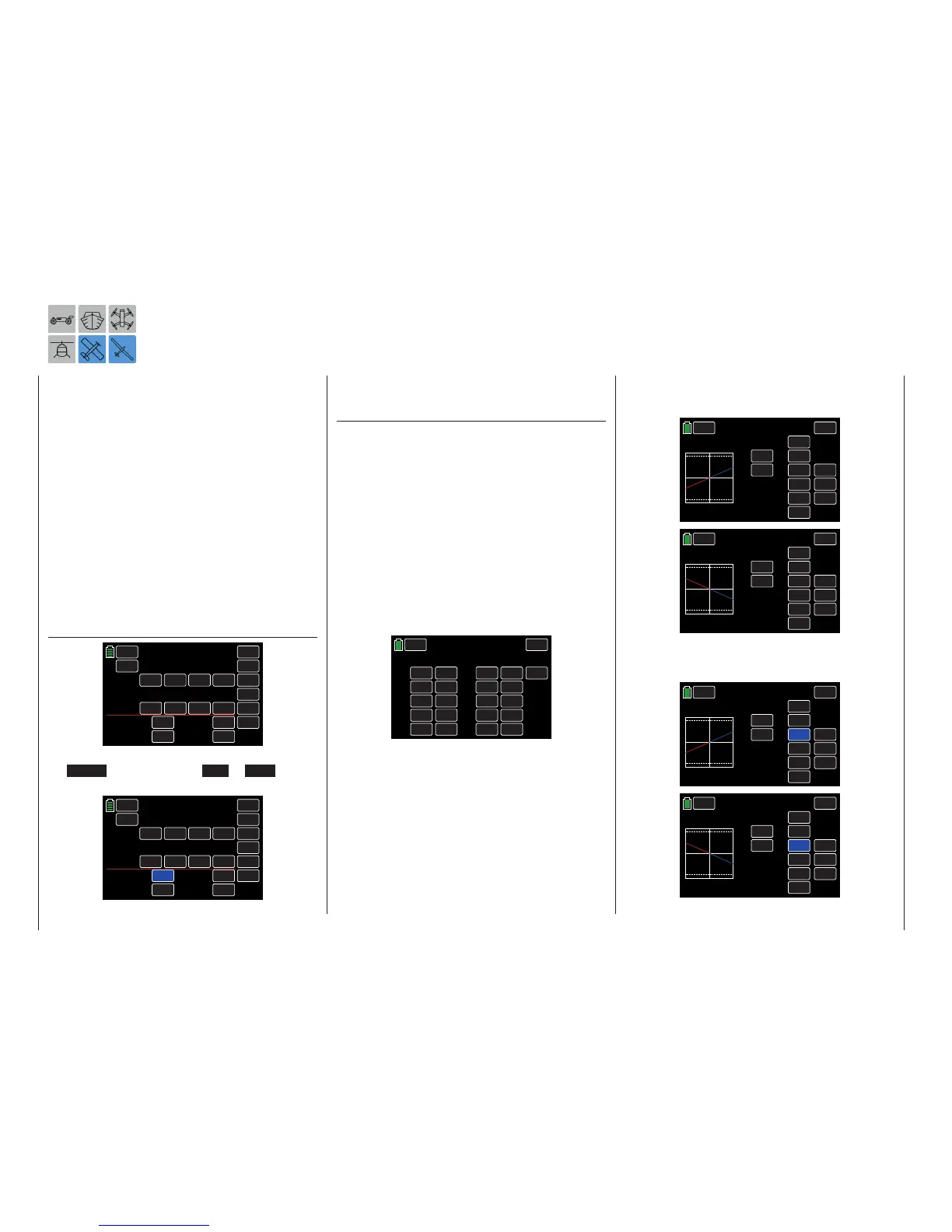

Programming

Turn on the transmitter and start programming the

flaps positions in the BASE submenu Trim Step.

Trim Step

BACK

PHASE 1

SERVO

T1

STEP

POS

SET

D.TRIM 1

T4

INC

RES

DEC

04

000%

000%

04

000%

NONE

NONE

04

04

T2 T3

000%

000%

000%

000%

000%

D.TRIM 2

SET

VIEW

INH

ON

AUTO TRIM

CO

CTL

Trim Step

In one of the two D.TRIM lines press to highlight blue

the NONE| button. Press the INC or DEC buttons

or the arrow keys ( pq ) to select CH6:

BACK

PHASE 1

SERVO

T1

STEP

POS

SET

D.TRIM 1

T4

INC

RES

DEC

04

000%

000%

04

000%

CH 6

NONE

04

04

T2 T3

000%

000%

000%

000%

000%

D.TRIM 2

SET

VIEW

INH

ON

AUTO TRIM

CO

CTL

Trim Step

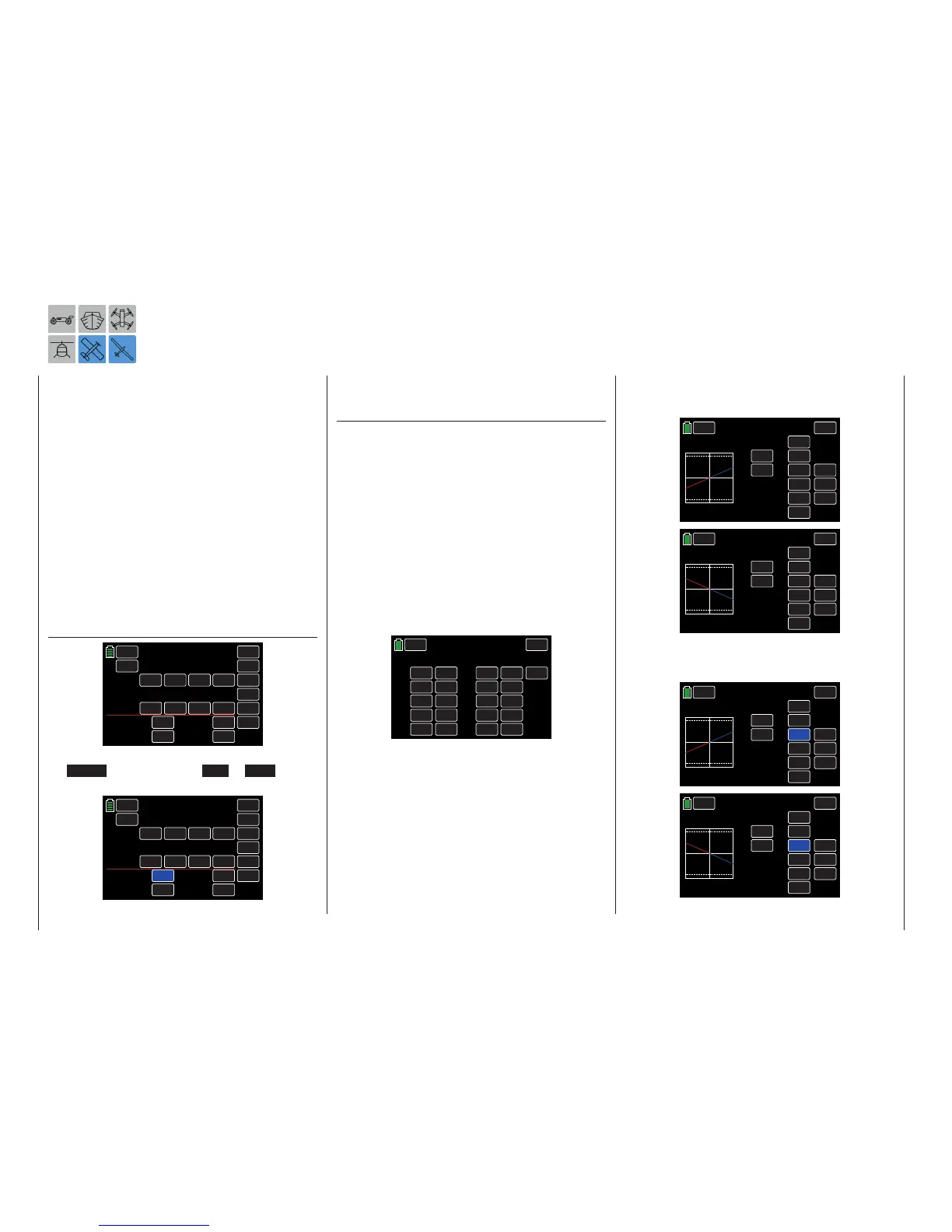

Back out and navigate to the FUNCTION submenu

Prog.MIX.

Prog.MIX

Bring up the desired phase.

Program the mixer numbers into the phase according

to the following schema:

• Left/Right Ailerons:

CH6 >> CH2

CH6 >> CH5

• Single Left/Right Flaps Pair:

CH6 >> CH6

CH6 >> CH7

• Second Left/Right Flaps Pair:

CH6 >> CH9

CH6 >> CH10

For a model type with 2AILE2FLAPS, reference the

“THERMAL” display example as follows:

2.

3.

4.

ON

ON

NEXT

ON

1.

ON

CH 6

CH 6

CH 6

CH 6

CH 5

CH 7

CH 6

CH 2

>>

>>

>>

>>

ACT

SLVMST

SET

5.

ON

CH 6

CH 3

>>

>>

>>

>>

>>

>>

BACK

THERMAL

SERVO

Prog.MIX

The mixing direction of the individual mixer pairs may

need to be set individually, depending on the wing

servos installation situation and the desired operating

direction of the selected digital trim button.

Individually setting mixing directions allows for con-

trasting and parallel mixing directions for each flap

pair:

CH6

A

OFFSET X

CTL

ON

000%

INC

RES

DEC

000%

CH2

>>

ACT

ON

B

OFFSET Y

+050%

+050%

BACK

THERMAL

SERVO

Prog.MIX

ON

OFF

TRIM

SYM

CH6

A

OFFSET X

CTL

ON

000%

INC

RES

DEC

000%

CH5

>>

ACT

ON

B

OFFSET Y

–050%

–050%

BACK

THERMAL

SERVO

Prog.MIX

ON

OFF

TRIM

SYM

In both cases, the trimming distance (max. 37.5% at

125% admixture) is determined according to the mix-

ing proportion:

CH6

A

OFFSET X

CTL

ON

000%

INC

RES

DEC

000%

CH2

>>

ACT

ON

B

OFFSET Y

+050%

+050%

BACK

THERMAL

SERVO

Prog.MIX

ON

OFF

TRIM

SYM

CH6

A

OFFSET X

CTL

ON

000%

INC

RES

DEC

000%

CH5

>>

ACT

ON

B

OFFSET Y

–050%

–050%

BACK

THERMAL

SERVO

Prog.MIX

ON

OFF

TRIM

SYM

230 Programming example - Flaps trimming

Loading...

Loading...