38 EDGE Pro Ti CNC Instruction Manual 807660

Installation

Installation requirements

•Table size

•Design

The following information is intended to assist with determining the weight of a gantry on a table that is accelerated by the

EDGE Pro Ti motors (031143).

A theoretical table configuration using a single-side drive with rack and pinion mechanics is the basis for the calculations.

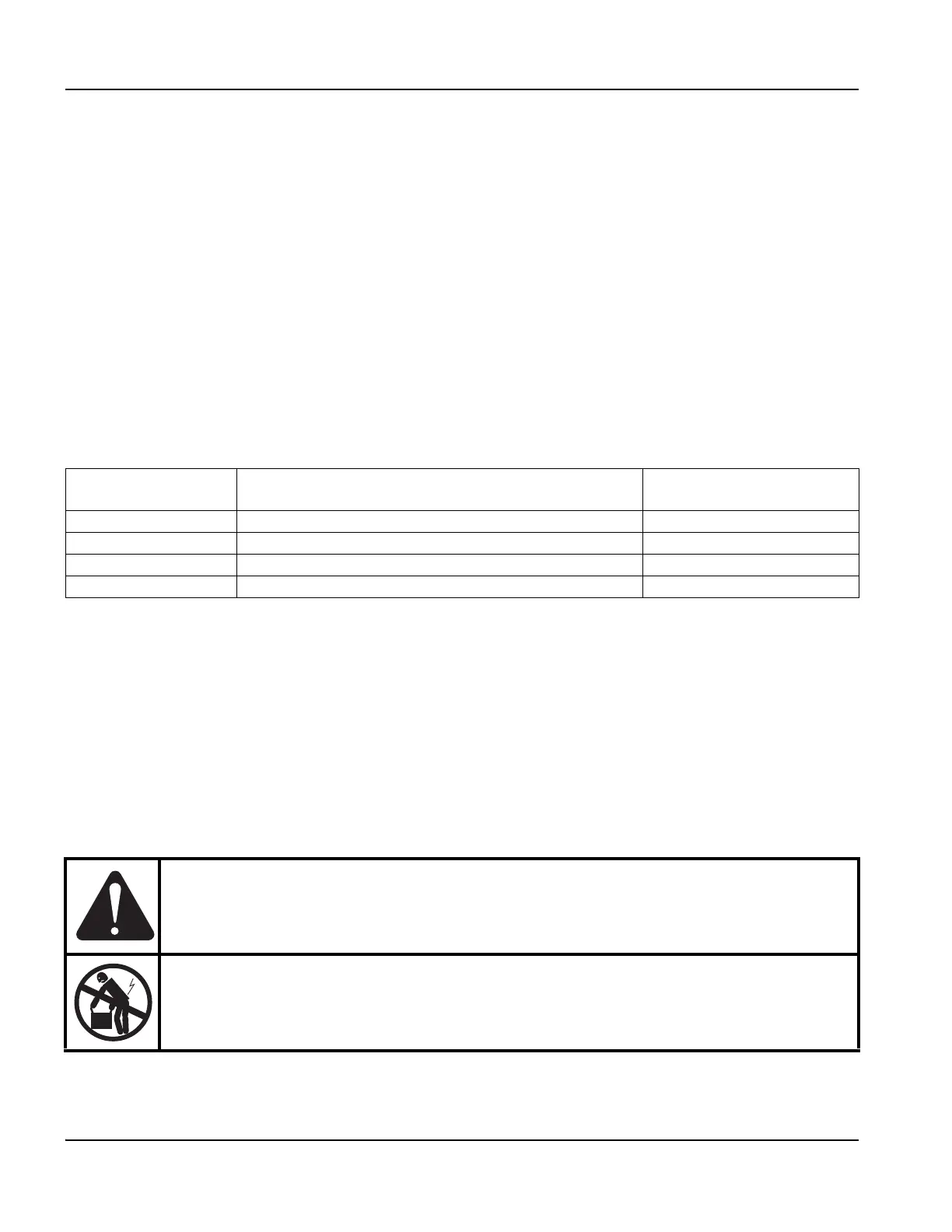

The pinion gear diameter is 50 mm (1.9 in.). Table 4 provides the suggested values for the weight of the gantry and

multiple gearbox ratios based on this hypothetical table.

Different table designs have different weight values. These values have been calculated with the torque equation, which

compares the maximum continuous torque of the motor to the theoretically calculated inertia of the cutting machine.

In the following table, the figure for maximum linear speed is based on the pinion diameter and gearbox ratio for a single

side drive using a 50 mm (1.9 in.) pinion gear. This figure does not include the limitations of table mechanics which can

significantly reduce this value. To determine the gantry weight for a dual gantry setup, increase the weight of the

single-side drive by 40%.

Table 4 Gantry sizing

Properly sizing the machine to performance specifications requires mechanical engineering and motion engineering

expertise. Table manufacturers are responsible for the optimal sizing and performance characteristics of the complete

machine. The EDGE Pro Ti can be used in many different configurations but the final performance characteristics of the

machine depend on the total solution provided by the table manufacturer.

Placement of system components

• Place all system components in position prior to making electrical, gas and interface connections. See

Mounting the CNC on page 39 for details.

• Ground all system components to earth. See Recommended grounding and shielding on page 43 for

grounding details.

Gear box ratio

Maximum linear speed

millimeter per minute/inch per minute

Gantry weight (kg/lb)

10:1 54966/2164 131/288

15:1 36652/1443 197/433

20:1 27483/1082 263/579

25:1 21996/866 329/724

WARNING!

Use a 2-man lift to position the EDGE Pro Ti CNC and avoid bodily injury.

Loading...

Loading...