EDGE Pro Ti CNC Instruction Manual 807660 59

Installation

Emergency stop (E-stop) connection

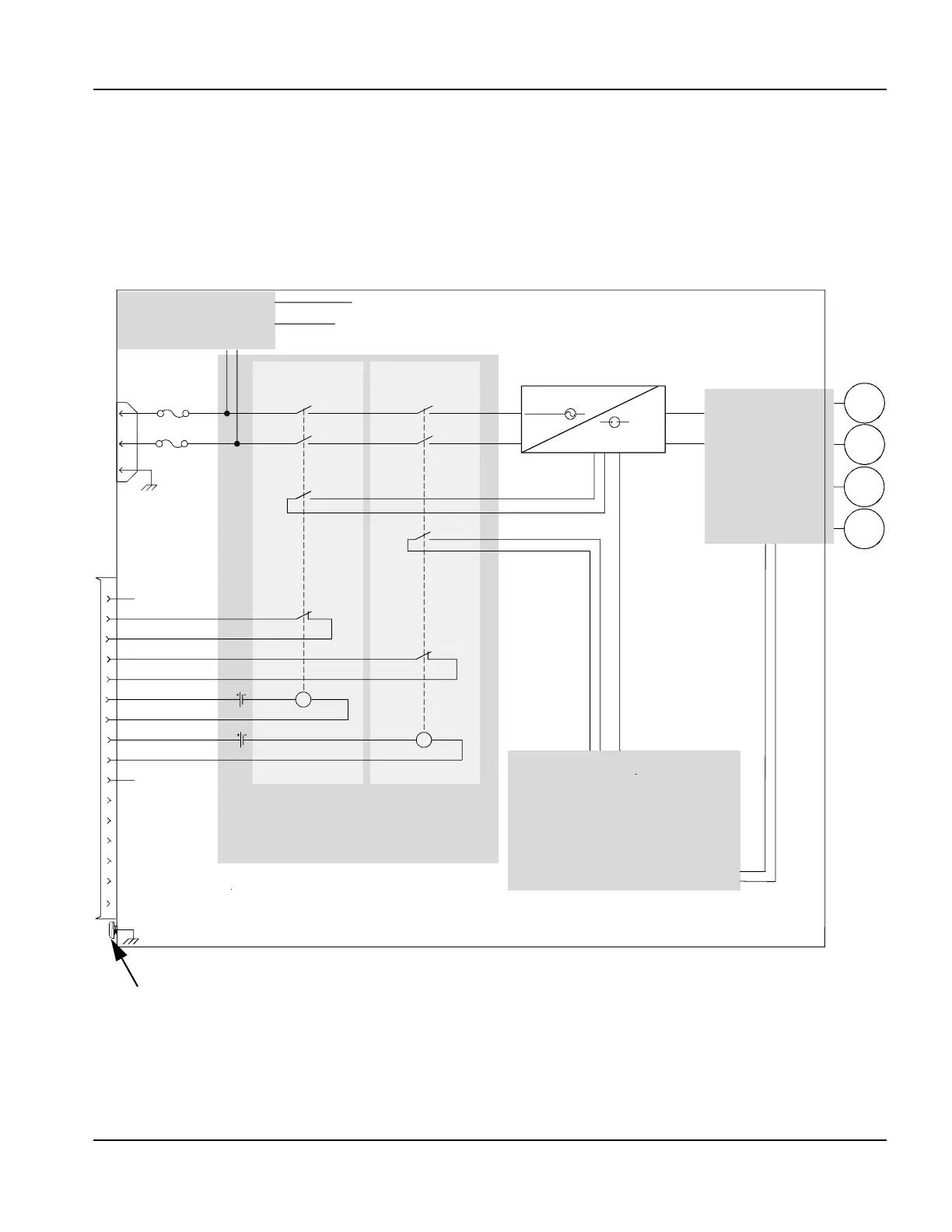

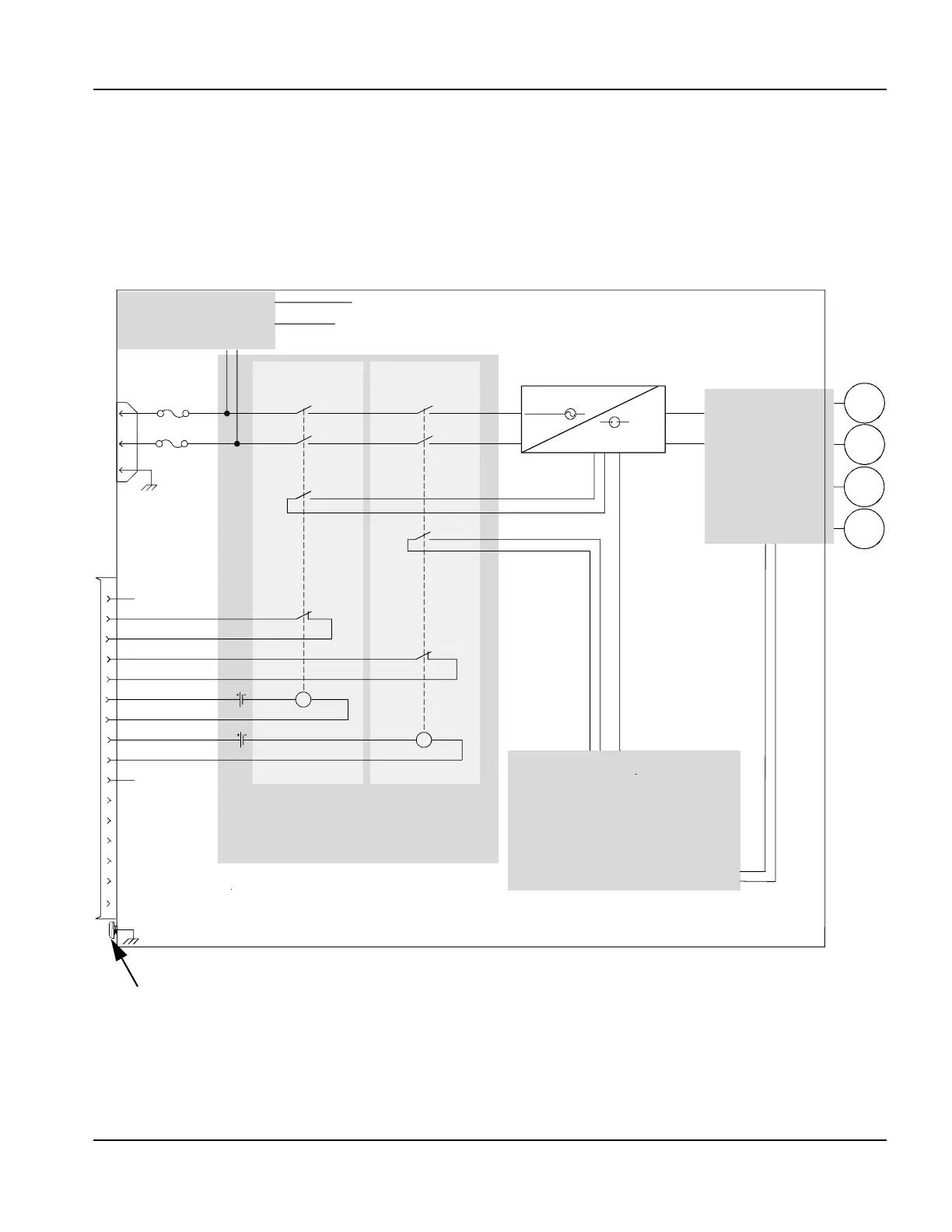

EDGE Pro Ti safety circuit

The EDGE Pro Ti CNC has a safety circuit that allows table manufacturers to implement E-stop or other safety measures

according the needs of their customers and their local and national safety regulations. Figure 21 illustrates this circuit.

Figure 20, illustrates an example of an E-stop design that might connect to the safety circuit within the EDGE Pro Ti

CNC through the E-stop connector on the rear panel of the CNC.

Figure 21 EDGE Pro Ti safety circuit

Power distribution

board

(page 121)

250 V, 10 A slow

blow fuse

1 +24 V

2 E-Stop monitor 1A

3 E-Stop monitor 1B

7 24 V coil 1B

6 24 V coil 1A

5 E-Stop monitor 2B

4 E-Stop monitor 2A

10 Field ground

9 24 V coil 2B

8 24 V coil 2A

AC

DC

Power

good

Servo board

(page 137)

current control

and

Z axis brake

M1

M2

M3

M4

60 V enable

E-stop

12 Not connected

11 Not connected

15 Not connected

14 Not connected

13 Not connected

Power good bit

E-stop input bit

I/O board to CNC

motherboard

(page 120)

Surge and safety

relay board

(page 142)

EDGE Pro Ti CNC

Relay LS1 with

force-guided

contacts

Relay LS2 with

force-guided

contacts

Normally open

Normally open

Normally closed

Normally closed

J6

CPC

EMI ground screw. Connect the ring terminal

from the E-stop cable shield.

16 Cable shield

Loading...

Loading...