EDGE Pro Ti CNC Instruction Manual 807660 73

Installation

I/O connection

Configuring I/O

The EDGE Pro Ti I/O circuitry provides inputs through optoisolators and outputs through relays. Contacts for both

normally open and normally closed outputs are available.

Use the DIP switch on the Relay I/O board (141278) to configure I/O.

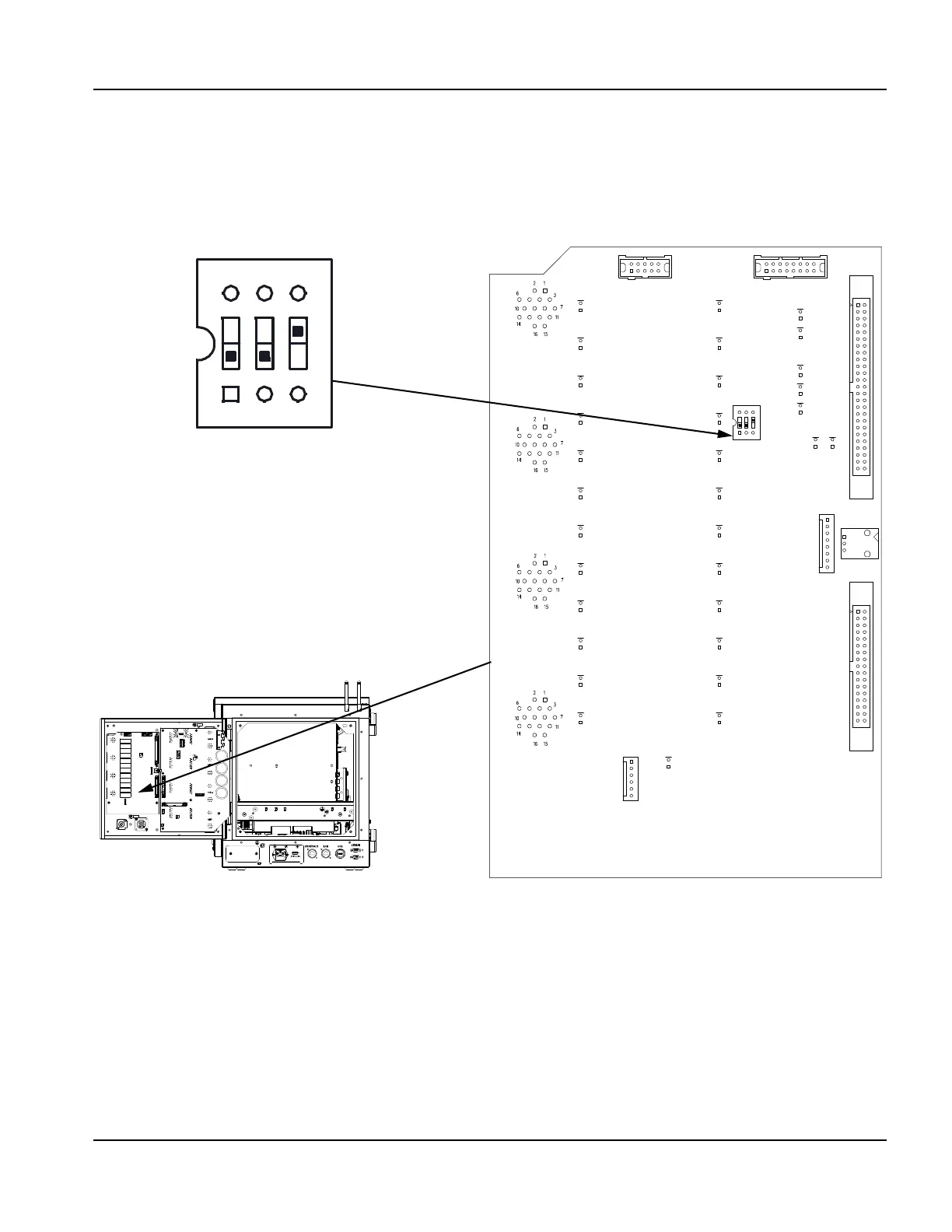

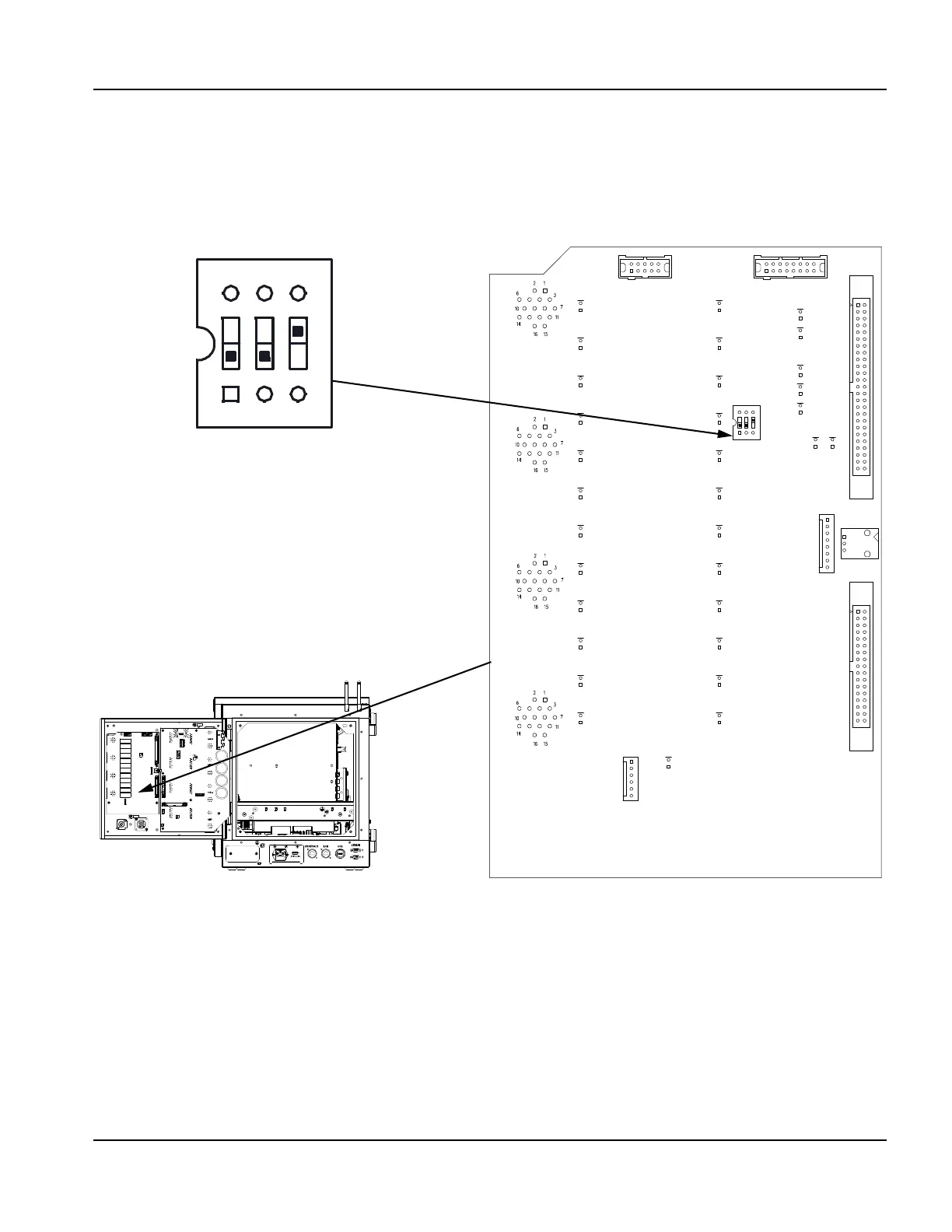

Figure 35 I/O configuration DIP switch

Shared inputs

General inputs 11 and 12 are shared with the limit switch inputs. However, the Sensor Ti lifter does not use limit switches

so position 1 and 2 must remain in the OFF (default) position. In this case, inputs 11 and 12 are available on the I/O

interface CPC connector as general purpose inputs.

If you are using a custom lifter with upper and lower limit switches, change position 1 and 2 to the ON position and select

sourced input mode (position 3 in the OFF position); this changes all general purpose I/O to sourced inputs. Wire the

limit switches to the lifter interface DB-9 connector.

Regardless of the type of lifter you install, do not wire to both the CPC inputs 11 and 12 and to the DB-9 lifter interface

connector inputs 11 and 12 simultaneously.

1

OFF

2

3

Default settings on the DIP switch

ON

12 3

On

Use lower limit

switch

Upper limit

switch

Dry contact

inputs (default)

Off

I/O 12

(default)

I/O 11

(default)

Sourced inputs

Loading...

Loading...