66 EDGE Pro Ti CNC Instruction Manual 807660

Installation

Motor connection

Regeneration circuit

When rapid deceleration of a motor brake creates additional, excessive voltage on the 60 VDC bus, the regeneration

circuit turns on a 10 Ohm resistor to divert the excess braking energy and lower the voltage. When the bus voltage

decreases, the resistor turns off.

When the resistor circuit turns on or off, the circuit sends an input signal to Phoenix software to report the change in

status. This signal is fixed as Input 14 in Phoenix software.

Users can monitor the regeneration circuit in the Watch Window on the Main screen in Phoenix software by turning on

the Regen Active status in the Watch Window setup. The oscilloscope function also allows users to monitor the

operation of the regeneration circuit. For more information on setting up the Watch Window or using the oscilloscope

function, refer to the Phoenix Software Operator’s Manual (806400).

The regeneration circuit should not be active for more than 25% of a single cut. See “Troubleshooting” on page 112 for

more information.

Motor cable

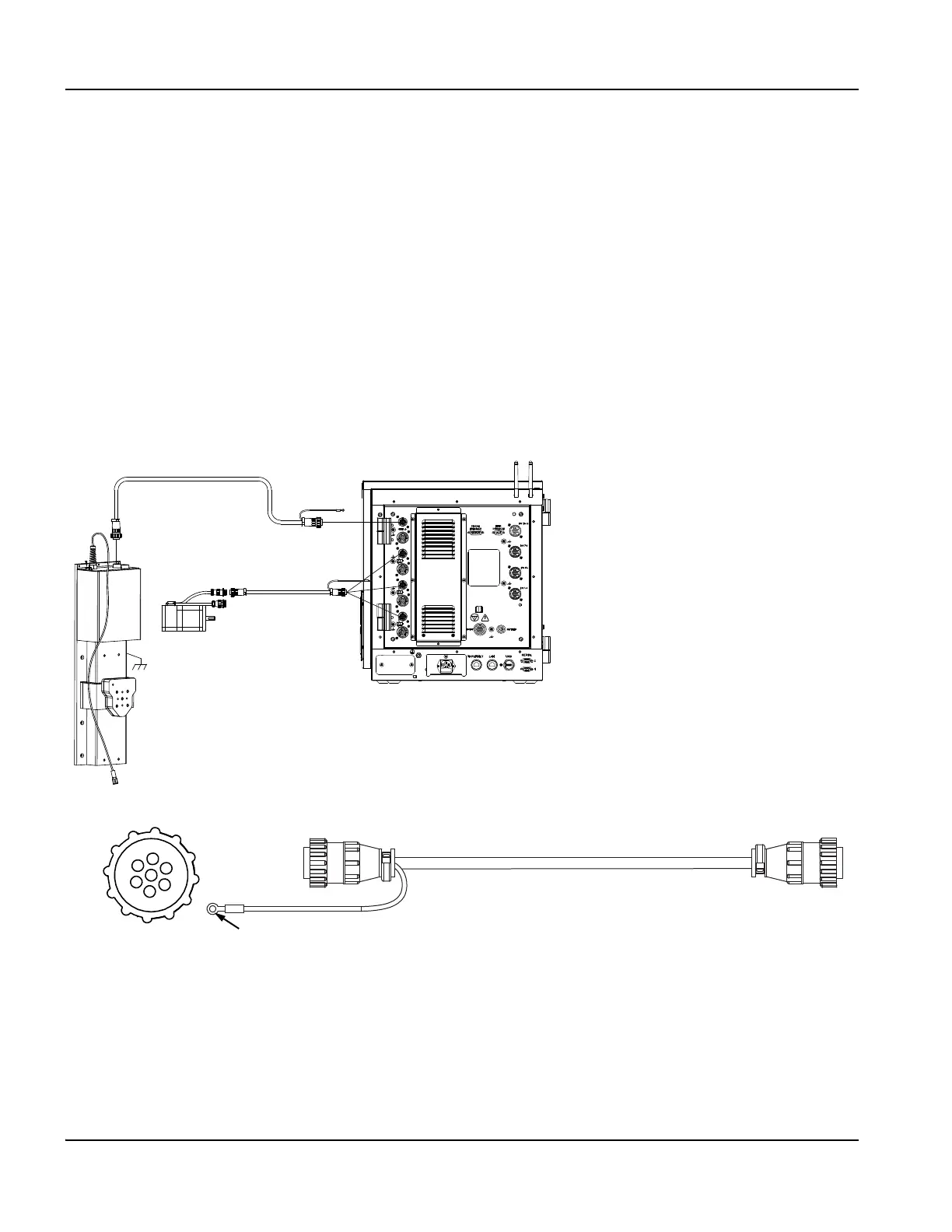

Figure 28 Motor cable from the CNC to the axes

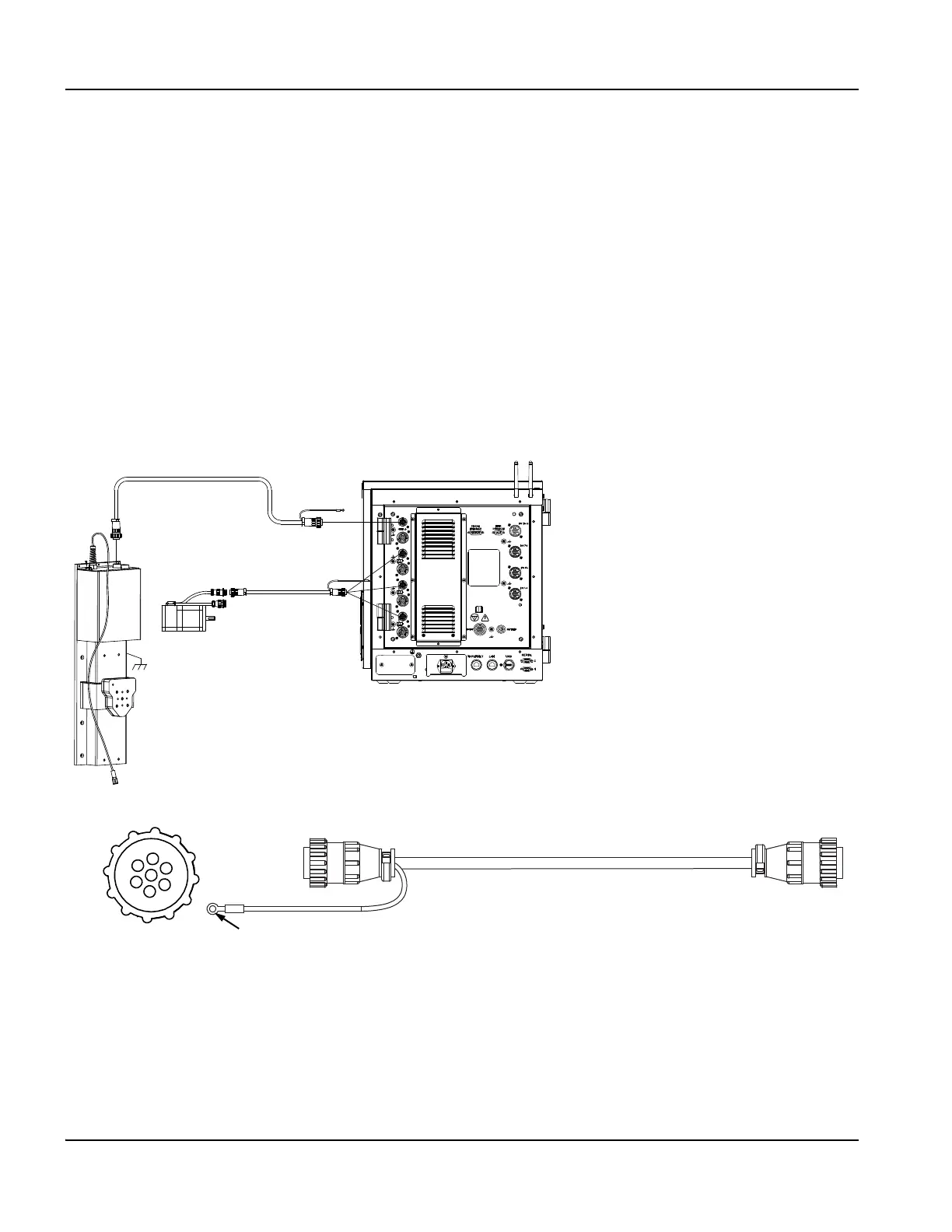

Figure 29 Motor cable

Motor cable to

axes 1, 2, and 3

Motor cable to

axis 4

Diameter = 11.6mm (0.458 in.)

Bend radius = 150 mm (6.0 in.)

Connect to motor connector ground stud

1

7

Loading...

Loading...