EDGE Pro Ti CNC Instruction Manual 807660 63

Installation

Motor connection

Motor connection

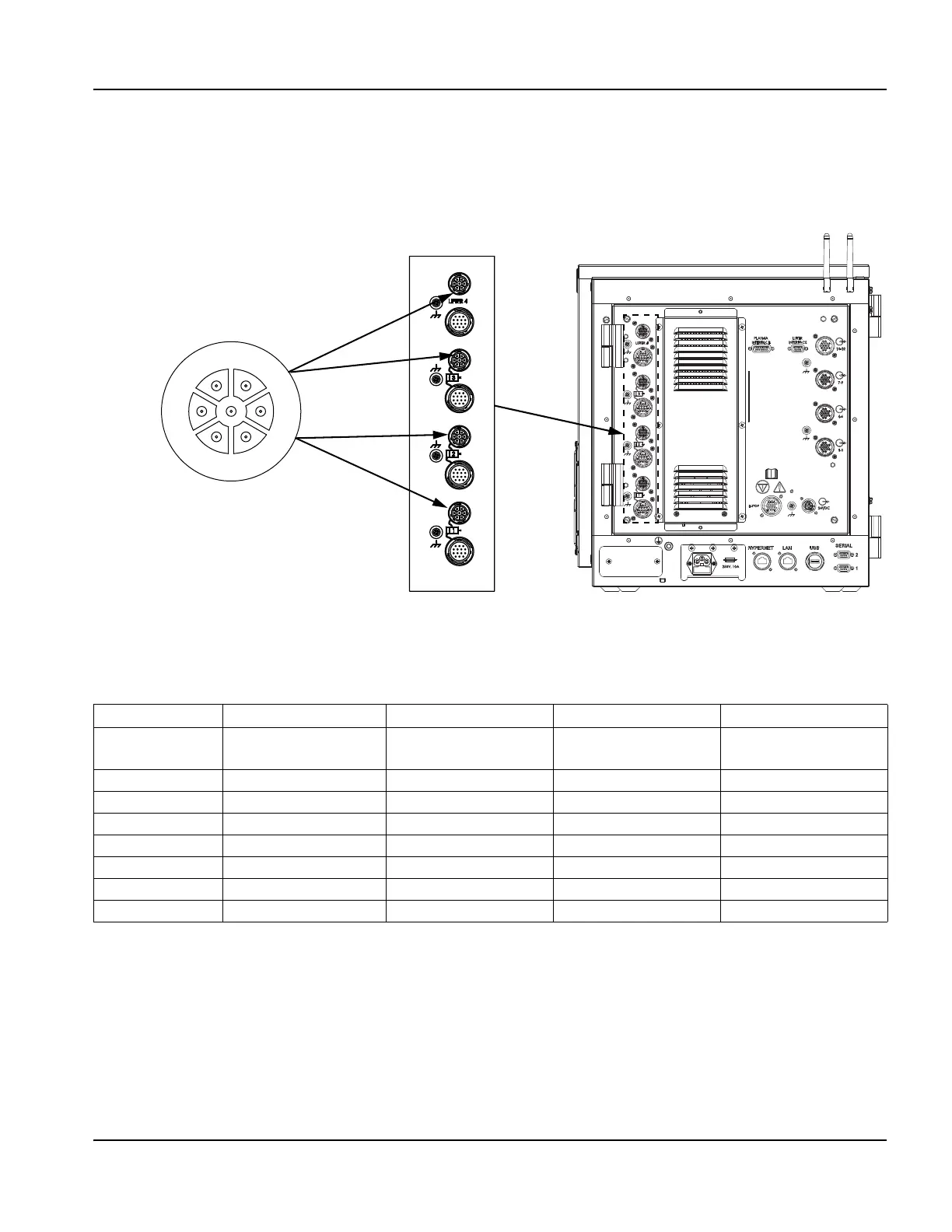

Install the motor cables between the Axis 4 motor connector and the motor connector on the Sensor Ti and between the

Axis 3, Axis 2, and Axis 1 motor connectors on the rear of the EDGE Pro Ti and the motor connector on the remaining

axis motors (031143). For more information about the motor cable, see Motor cable on page 66.

Figure 25 Ti motor interfaces

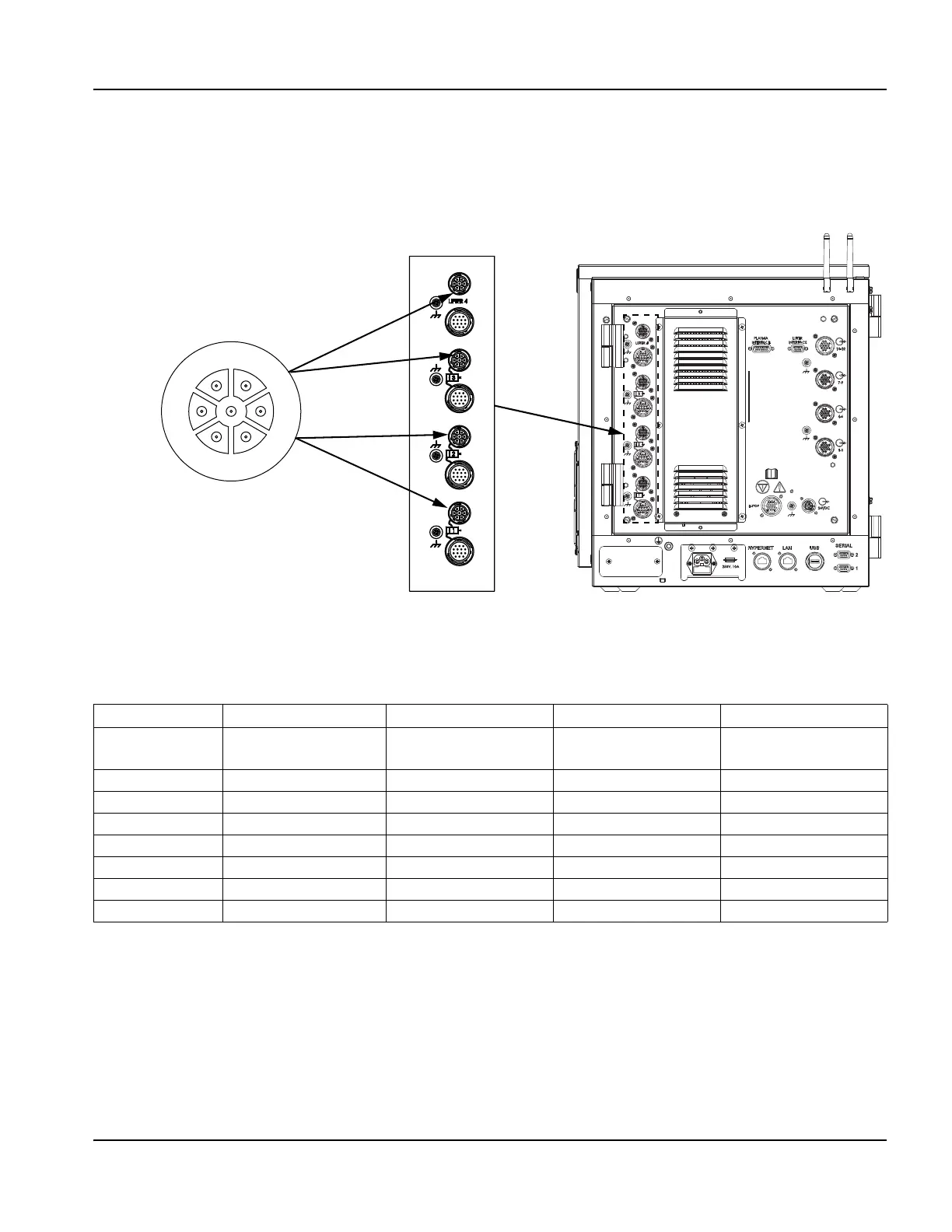

Table 7 Pinouts for motor interfaces

Note:

• Select brushed or brushless mode for the motor on each axis using the DIP switch on the Ti servo board

(141281) inside the back door of the CNC. A single EDGE Pro Ti can have both brush and brushless

motors if switches are set properly. For more information, see Axis configuration on page 64.

• Axis 4 is the only axis that supports a lifter. It is the only axis that supplies the 24 VDC that is required to

disable a lifter’s electromechanical power-off brake.

• For optimum noise immunity, cable shields should be tied externally to the CNC enclosure.

Pin no. Axis 4 – Lifter Axis 3 (Dual gantry) Axis 2 (Y or X) Axis 1 (X or Y)

Motor

connectors

J16 J15 J14 J13

1 Motor/brake A Motor/brake A Motor/brake A Motor/brake A

2 Motor/brake B Motor/brake B Motor/brake B Motor/brake B

3 Motor/brake C Motor/brake C Motor/brake C Motor/brake C

4 Brake+ (24 VDC) Brake+ (dry contact) Brake+ (dry contact) Brake+ (dry contact)

5 Brake- (common) Brake- (dry contact) Brake- (dry contact) Brake- (dry contact)

6 Shield Shield Shield Shield

7 Shield Shield Shield Shield

Axis 1

12

5

3

76

Axis 2

Axis 3

Axis 4 – lifter

Motor connector

Loading...

Loading...