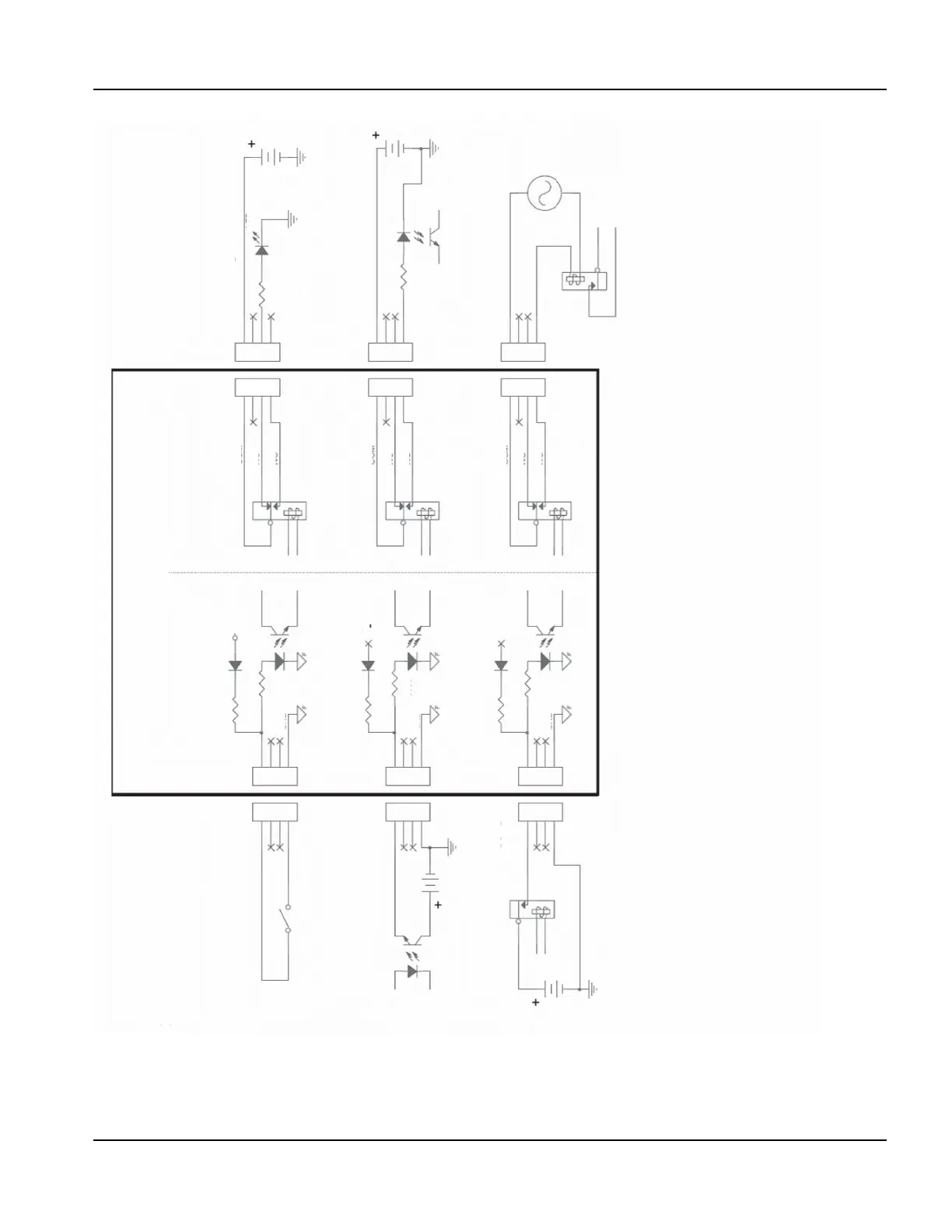

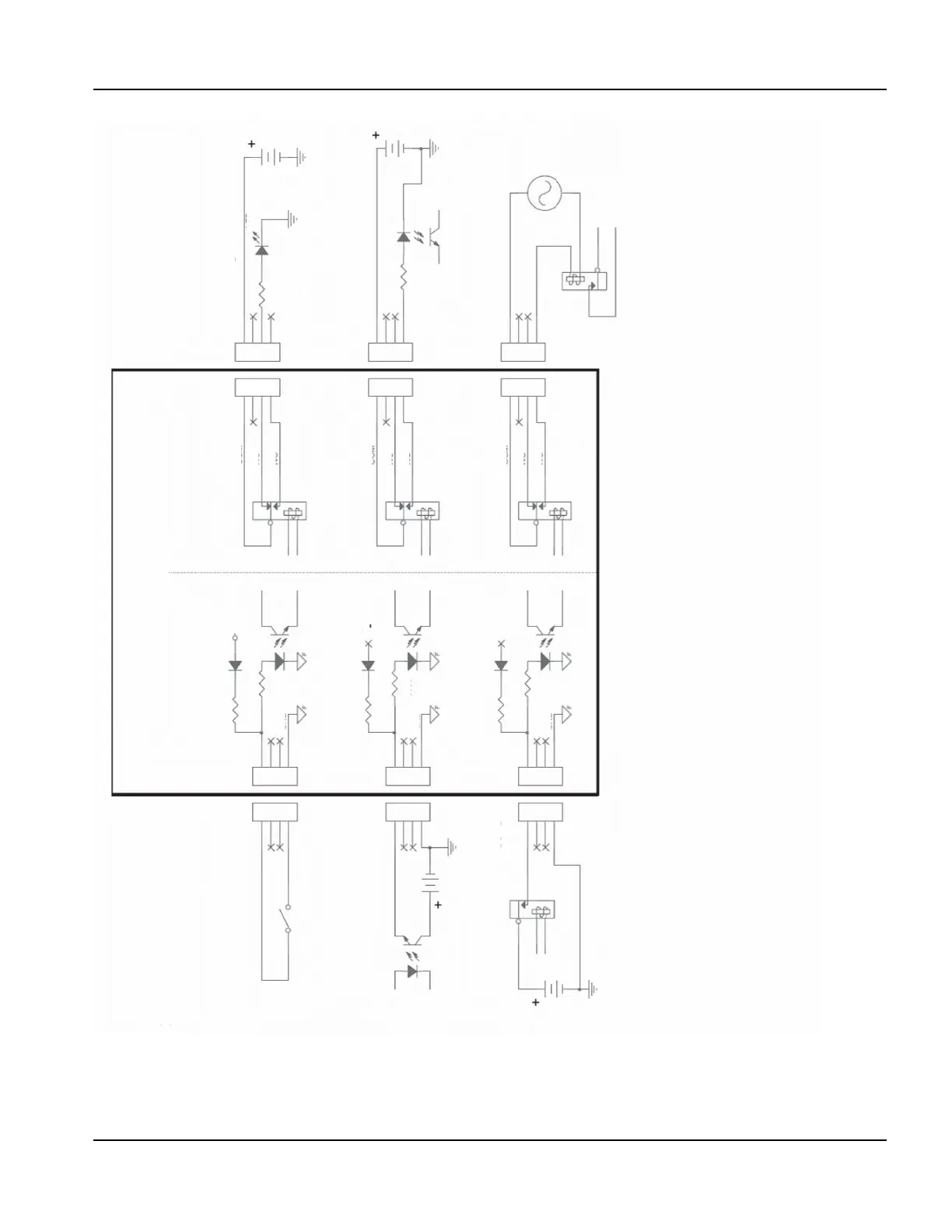

Internal Circuitry

Outputs

Inputs

Example Inputs

External circuitry

Example Outputs

External circuitry

Dry contact inputs

Note: Logic level reversal

Normal sourced inputs

Use external +12 V supply

Dry contact inputs

DIP Switch 1-C closed

Normal sourced inputs

DIP Switch 1-C open

Normal sourced inputs

DIP Switch 1-C open

Use external +12V supply and

normally closed contact

Use external +5 V supply and

normally open contact

Use external 24 VAC and normally

open contact

Normal sourced inputs

Use external +12 V supply

Resistor

Optoisolator

Optoisolator

Relay

Relay SPDT

Relay SPDT

Relay SPDT

Relay

Resistor

External grounds

24 VAC

Switch

12 V

24 V

External ground

12 V

External

ground

Ground

5 V

LED

common

normally closed

normally open

common

normally closed

common

normally closed

normally open

normally open

24 V Field

Ground

Ground

Open

Open

3900

3900

3900

3900

3900

3900

Note:

• To prevent damage, do not apply more than 24 VDC to any optoisolator input and verify the correct signal

polarity.

• Do not exceed the following voltage and amperage ratings through any relay output:

• For outputs 1-12 and Plasma Start: 30 VAC or VDC/1 A. The rating is the same for both AC or DC.

• For the brakes 1-4: 30 VDC/1 A or 30 VAC/0.5 A.

• For Hold Ignition: 30 VDC/10 mA, polarity is important.

Loading...

Loading...