IS810N-INT Series Servo System User Manual (Brief) Chapter 7 Troubleshooting

- 236 -

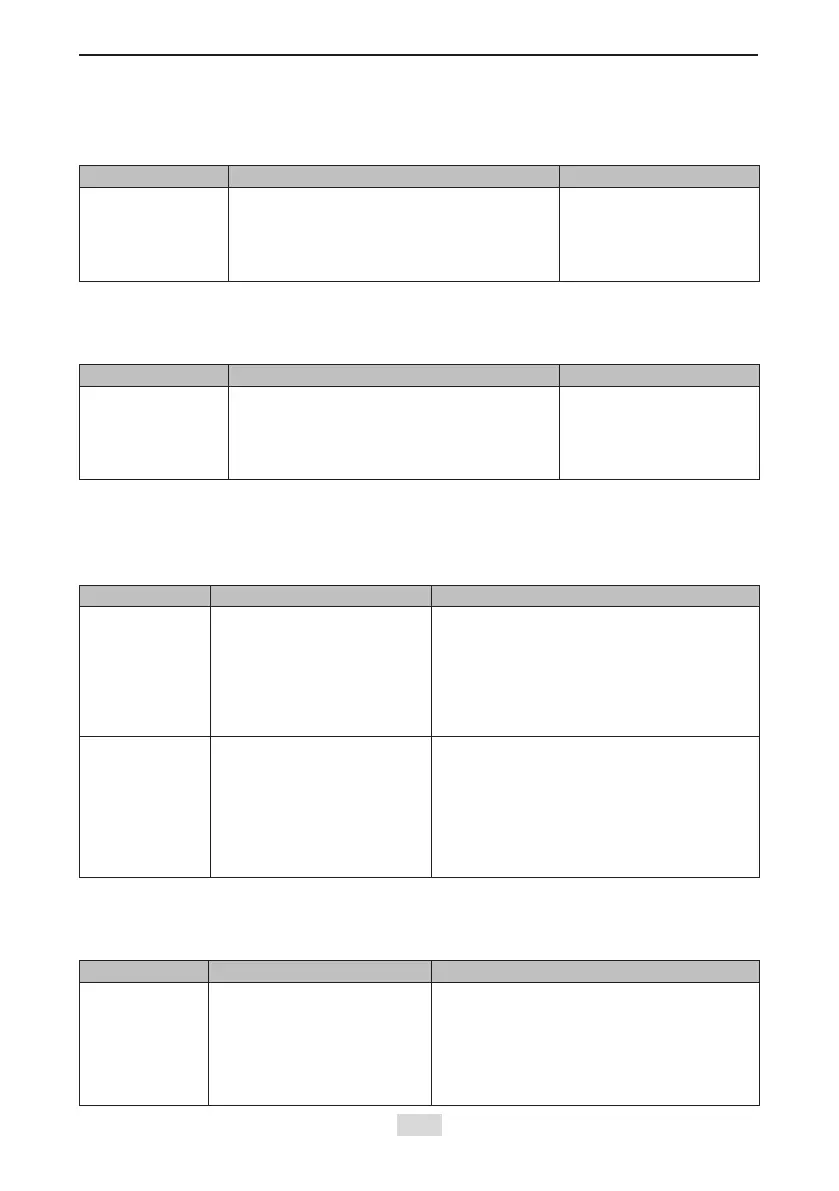

E1.121: invalid S-ON command

Cause:

When some auxiliary functions are used, a redundant S-ON signal is given.

Probable Cause Conrming Method Corrective Action

When the servo

drive is enabled

internally, the S-ON

signal is turned on

via communication.

Check whether the S-ON signal is sent

from the host controller when the auxiliary

functions (200D-03h, 200D-04h, 200D-0Ch)

are used.

Turn off the S-ON signal

from the host controller.

E1.122: product matching fault in the absolute position mode

Cause:

The motor does not match in the absolute position mode or the motor SN is set incorrectly.

Probable Cause Conrming Method Corrective Action

The motor does not

match in absolute

position mode or

the motor SN is set

incorrectly.

View the motor nameplate to check whether

the motor is a multi-turn absolute encoder

motor.

Check whether H0000 (Motor SN) is correct.

Set H0000 (Motor SN)

correctly according to the

motor nameplate or use a

matching motor.

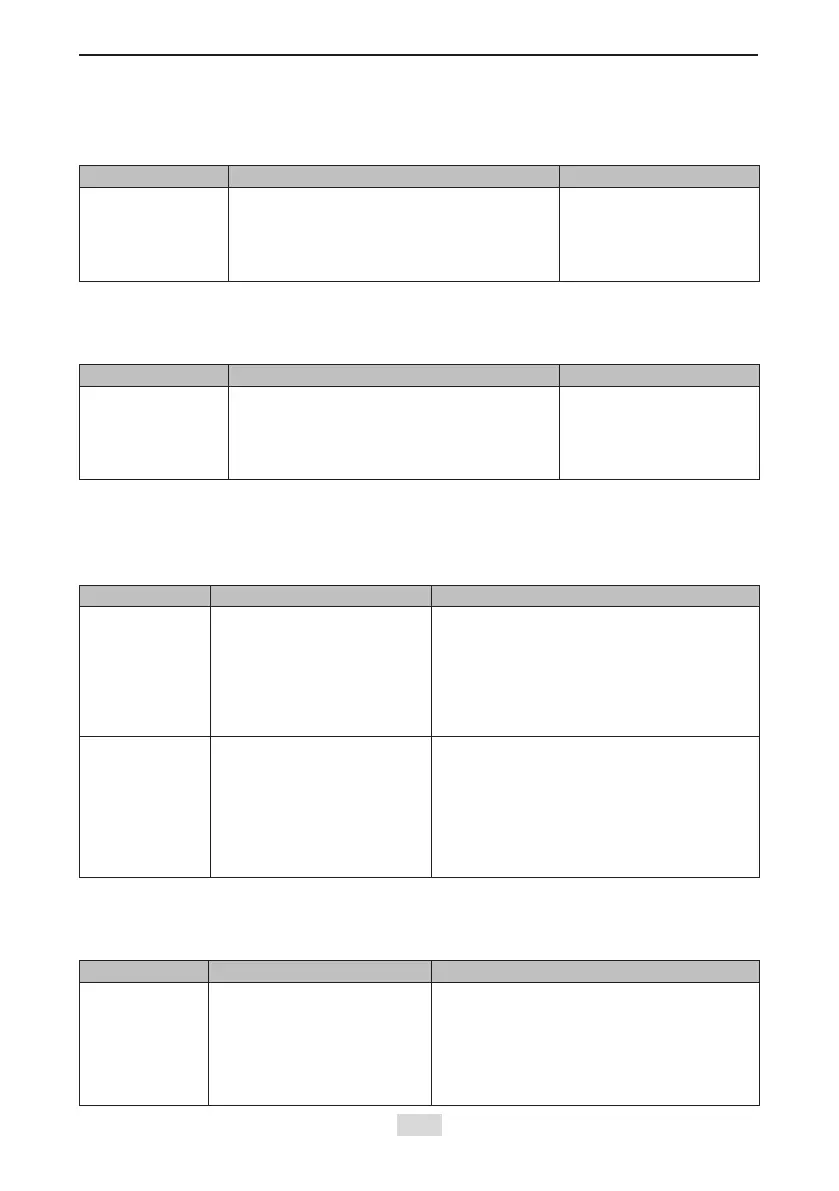

E1.130: DI function setting error

Cause:

The same function is allocated to different DIs.

The set values are not supported.

Probable Cause Conrming Method Corrective Action

1. The same

function is

allocated to

different DIs.

View 2003-03h, 2003-05h,

and 2003-07h to 2003-11h

to check whether they are

allocated with the same non-

zero DI function No.

Allocate parameters that have been

allocated with the same non-zero DI function

No. with different DI functions. Then turn

on the control power again to allow the

modications to take effect. You can also

turn the S-ON signal off and give the reset

signal to make the modication take effect.

2. DI function

set values are

incorrect.

Check whether the set values

in 2003-03h, 2003-05h, and

2003-07h to 2003-11h do not

meet the requirements.

Requirements for set values:

Axis No. + Supported DI

function No.

Set values according to the requirements for

set values. Then turn on the control power

again to allow the modications to take

effect. You can also turn the S-ON signal

off and give the reset signal to make the

modication take effect.

E1.131: DO function setting error

Cause:

The set values are not supported.

Probable Cause Conrming Method Corrective Action

DO function

set values are

incorrect.

Check whether the set values

in 2004-01h and 2004-03h do

not meet the requirements.

Requirements for set values:

Axis No. + Supported DO

function No.

Set values according to the requirements for

set values. Then turn on the control power

again to allow the modications to take

effect. You can also turn the S-ON signal

off and give the reset signal to make the

modication take effect.

Loading...

Loading...