The reaction to the warning is freely adjustable. All setting options for configurable

errors are available.

The default setting is "Warning". This means: upon reaching the pre-warning tem-

perature, bit 2 is set in ru02 warning bits and with respective setting of the warning

mask also bit 7 in the status word.

pn06 defines how the reference level for generating the overtemperature warning

is determined (for the description of pn06 see chapter 4.4.3 Overtemperature

heatsink (OH)).

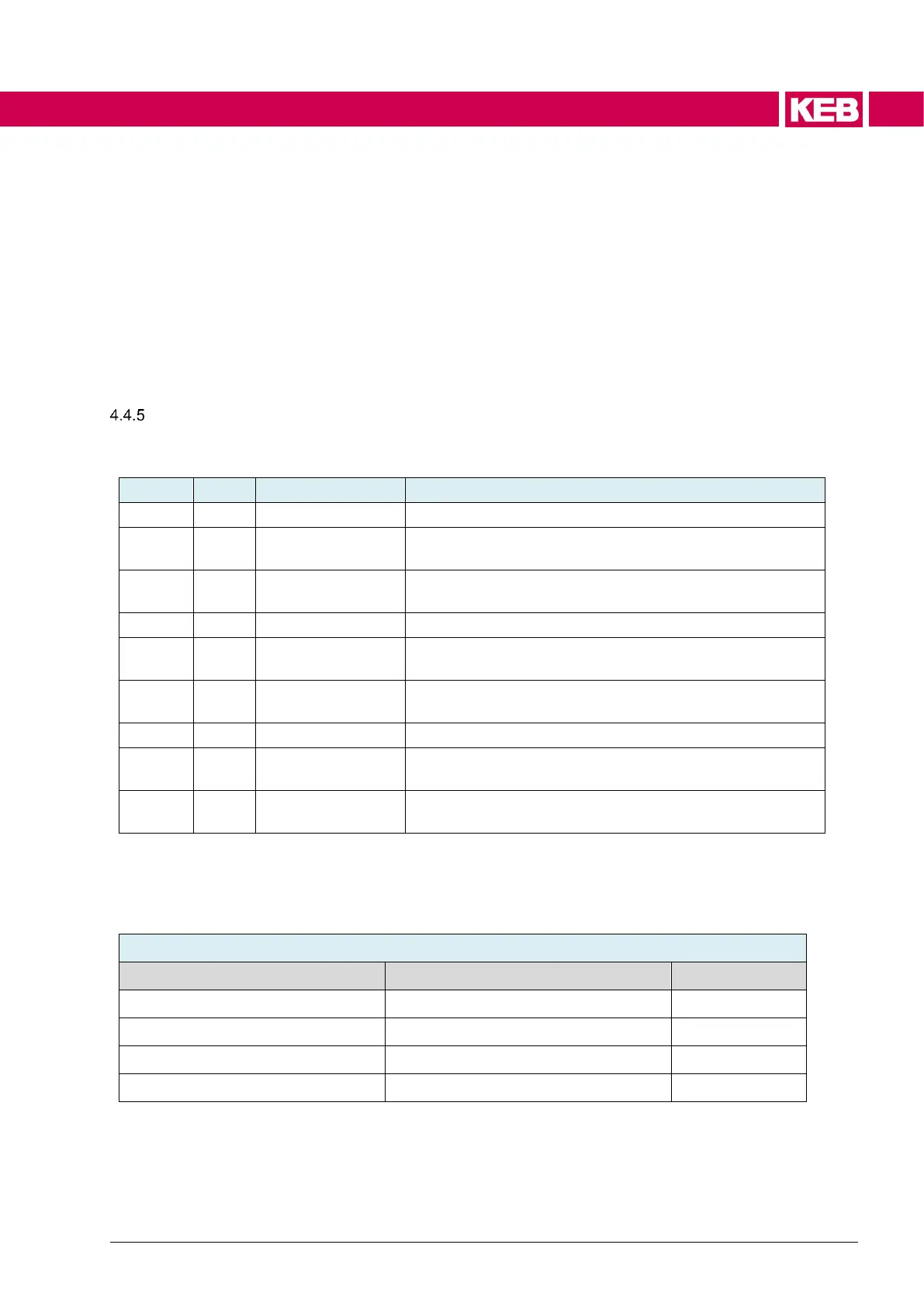

Overtemperature motor (dOH)

The monitoring of the motor temperature can be influenced via the following ob-

jects:

Display of the motor temperature

0 = KTY 84-130, 1 = PTC, 2 = via encoder, 3 = KTY 83

110, 4 = PT1000, 5 = freely defined sensor characteristic

Motor temperature at which a warning is triggered

(not valid for PTC evaluation)

Error reaction (=> see Chapter 4.3.1 Errors)

Only active for PTC: time between triggering of the PTC

(sets the warning bit) and triggering of error dOH

Motor temperature at which an error is triggered

(not valid for PTC evaluation)

Display of the warnings bit-coded (=> 4.3.3 Warnings)

Mask for warning bit in the status word (=> 4.3.3 Warn-

ings)

Parameter structure for the definition of a customer-spe-

cific characteristic for detection of the motor temperature

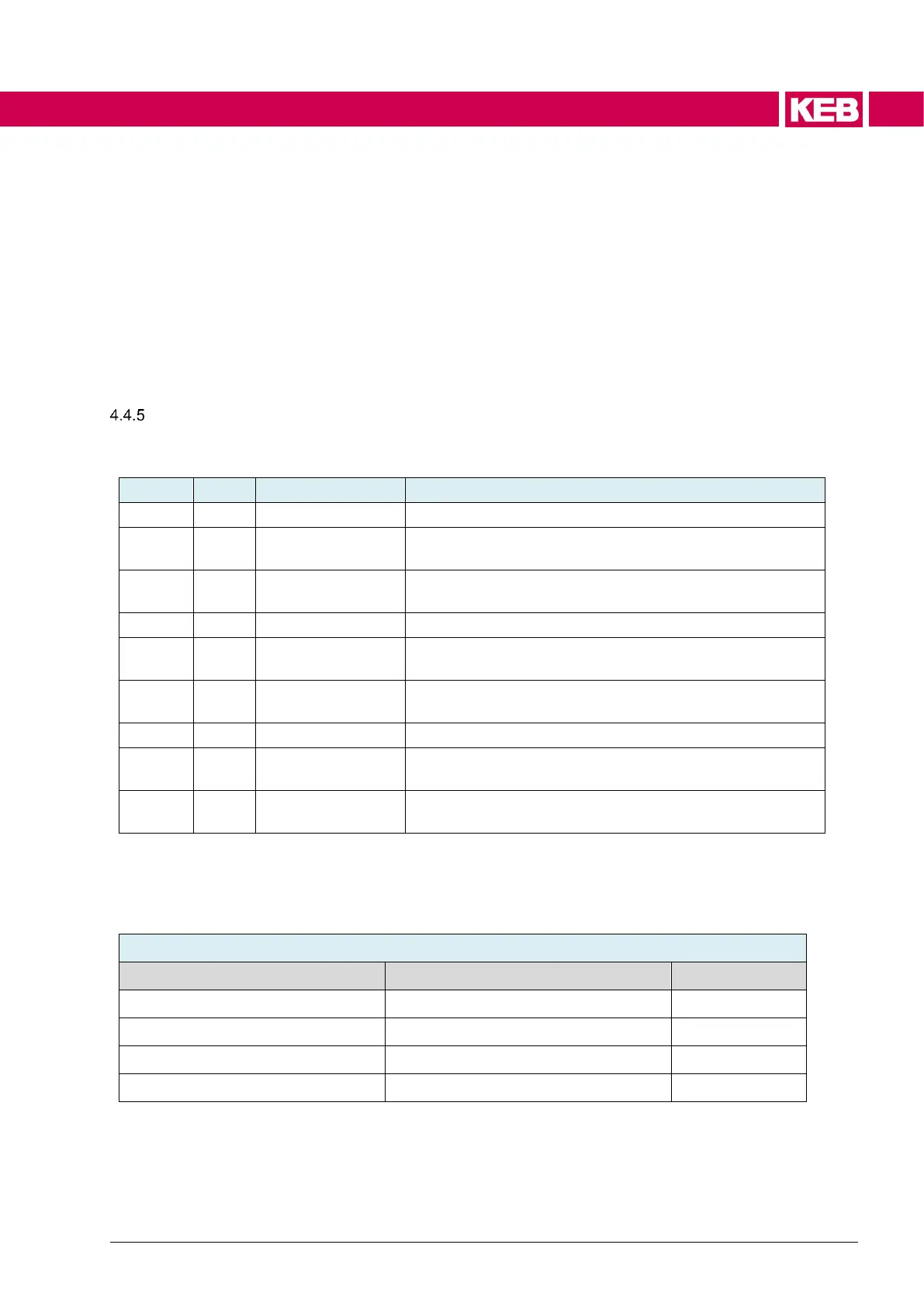

4.4.5.1 PTC evaluation

Values of ru28 motor temperature when using a PTC sensor:

PTC according to DIN EN 60947-0

0.75…1.5kΩ reset resistance

Transition T1-T2 open => closed

1.65k…4kΩ response resistance

Transition T1-T2 closed => open

Loading...

Loading...