134 Kollmorgen - December 2011

MMC Smart Drive Hardware Manual - 460V 3 PHASE MMC SMART DRIVE NEXTGEN

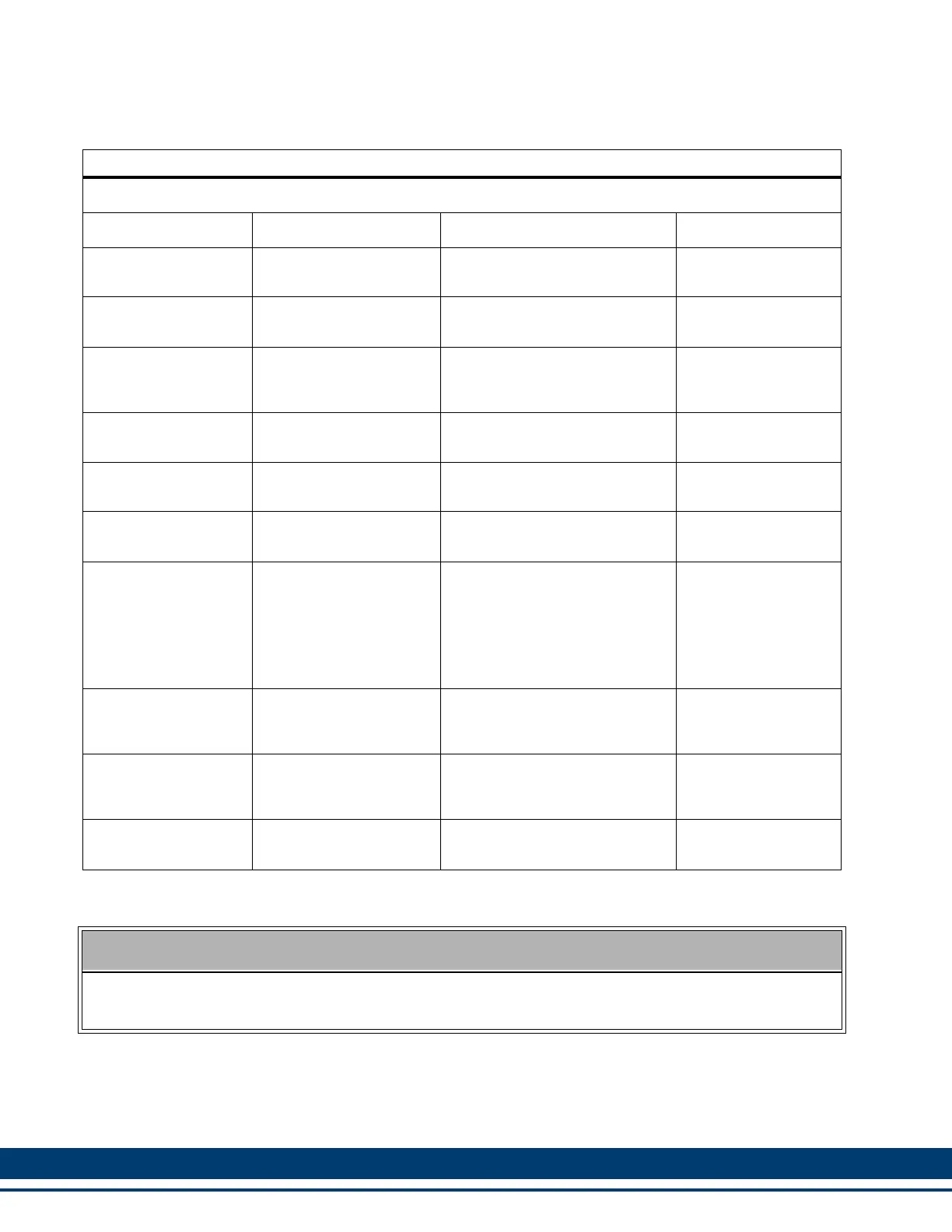

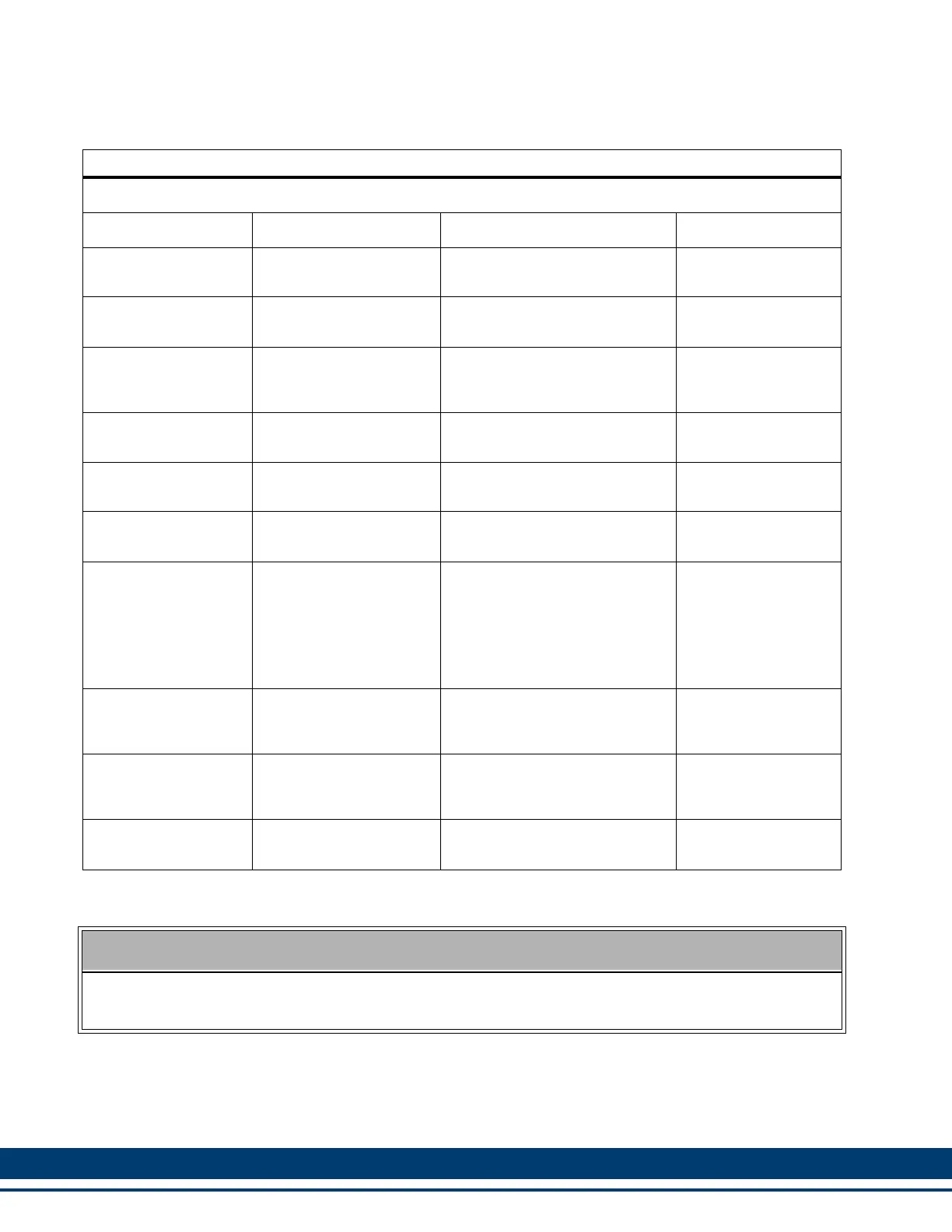

Table 6-4: Pin Description for Feedback Connector (F1)

F1 Feedback Signals

Signal Type Signal Name Notes Pin

Incremental Encoder

Inputs

A1, A1/, B1, B1/, I1, I1/

Differential A quad B encoder

signals.

12, 13, 14, 15, 6, 7

Sinewave Encoder In-

puts

Sin, Sin/, Cos, Cos/ Sinewave Encoder signals 12, 13, 14, 15

Sinewave Encoder

Data Channel In/Out

RS-485 Data +, RS-485

Data -, RS-485 Clock+,

RS-485 Clock-

RS-485 signals for connecting

the Sinewave Encoder Data

Channel to the drive

6, 7, 2, 3

SFD Communication

Channel (future)

Com+, Com- SFD communication signals 6, 7

Resolver Inputs Sin+, Sin-, Cos+, Cos-

Resolver stator feedback sig-

nals

12, 13, 14, 15

Resolver Outputs Carrier+, Carrier-

Resolver rotor excitation sig-

nals.

6, 7

Temperature Input Temperature

Thermostat (normally- closed)

or Thermistor (Phillips KTY84-

130 PTC or equivalent recom-

mended) input for detecting

over temperature conditions

within the motor. These inputs

are shared with F2.

8, 9

+5V Encoder Power

Outputs

+5V Source

Regulated +5VDC for powering

the attached encoder (350ma

max).

10

+5V Encoder Power

Sense Lines

+5V Sense+, +5V

Sense-

These signals should be tied to

the +5V power and ground lines

at the encoder.

4, 5

Signal and Power

Common

Common

Return path for feedback sig-

nals and +5V power output

11

PROVIDING 8VDC ENCODER POWER

Some Encoders, specifically the Stegmann Hiperface, require 8VDC power to operate. 8VDC Power

can be provided on pins 10 and 11 by connecting the +5V Sense Lines (pins 4 & 5) together.

Loading...

Loading...