236 Kollmorgen - December 2011

MMC Smart Drive Hardware Manual - MOTOR CABLES & CONNECTORS

Doubling the minimum bending radius for reeling applications can triple cable life at

the maximum recommended tension. Therefore, the largest possible bending radius

should be used to increase cable life.

9.1.2 Cable Tension

Cable tension plays an extremely important role in determining cable life in reeling.

The copper conductors are the principle strength member in flexible cable

constructions. Even if strain relief fittings are used on the cable ends, most of the

tension will still be supported by the copper conductors.

The effects of tension on a cable are dependent upon the pounds per cross-sectional

area of the copper conductors. Larger AWG wires and/or more conductors can handle

more tension than smaller AWG wires and/or fewer conductors.

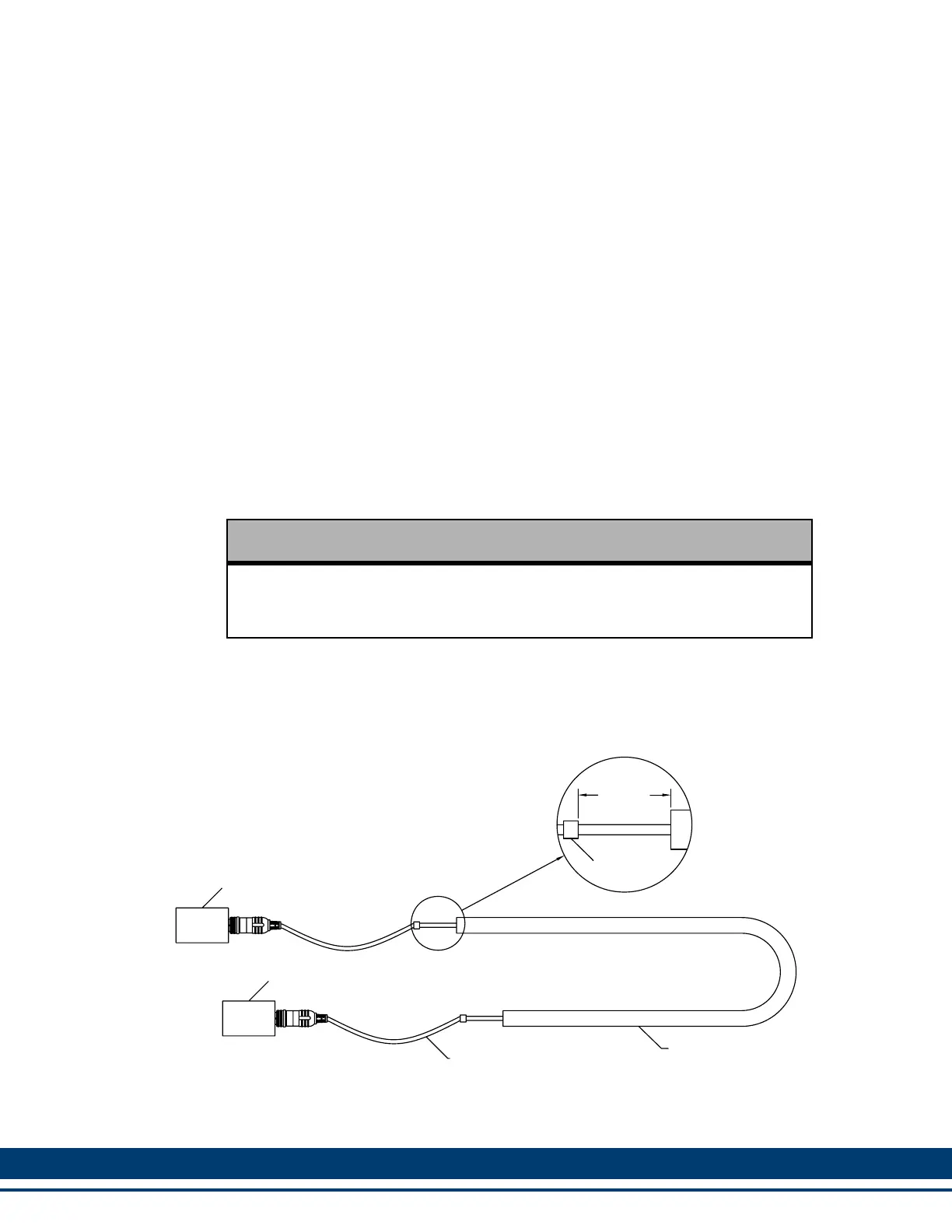

9.2 Flex Cable Installation

Cables should be fixed on both ends to relieve them of tensile loads and prevent any

loads from being applied to the molded connectors. At a minimum, the cables have to

be fixed on the moving end of the track. A distance of 3 to 6 inches from the track to

the fixation point is recommended (See Figure 9-1).

Figure 9-1: Flex Cable Installation

Observe the following precautions when installing flex cables:

WARNING: CABLE DAMAGE

Failure to properly isolate Flex, Pull, and Torsional forces from the connector

ends will result in electrical and mechanical breakdown. Over clamping at the

fixation point can result in cable damage.

.ONFLEXINGAREA.OSTRESSBETWEEN

FIXATIONPOINTANDCONNECTORMOUNTING

4RACK

#ONNECTOR-OUNTING

#ONNECTOR-OUNTING

TO

INCHES

&IXATION

POINT

Loading...

Loading...