Chapter 5 Positioning Instructions

5 - 78

•The range of the main axis setting of MST_AXIS is 0 ~ 9 as shown below. If this range is exceeded,

error code 355 is generated.

•To cancel the execution of speed synchronization instruction, run the stop instruction (APM_STP)

for the sub-axis.

•Speed synchronization control can be executed even when the Origin of the sub-axis has not be

determined.

•In speed synchronization, the sub-axis is synchronized to the main axis. Therefore, even if the

control mode of the sub-axis is set up position control, it repeats start and stop according to the

operation of the main axis, and the direction of rotation of the sub-axis is the same as that of the

main axis.

•If the M code of the sub-axis is ON at the execution of the speed synchronization instruction, error

code 353 is outputted to STAT.

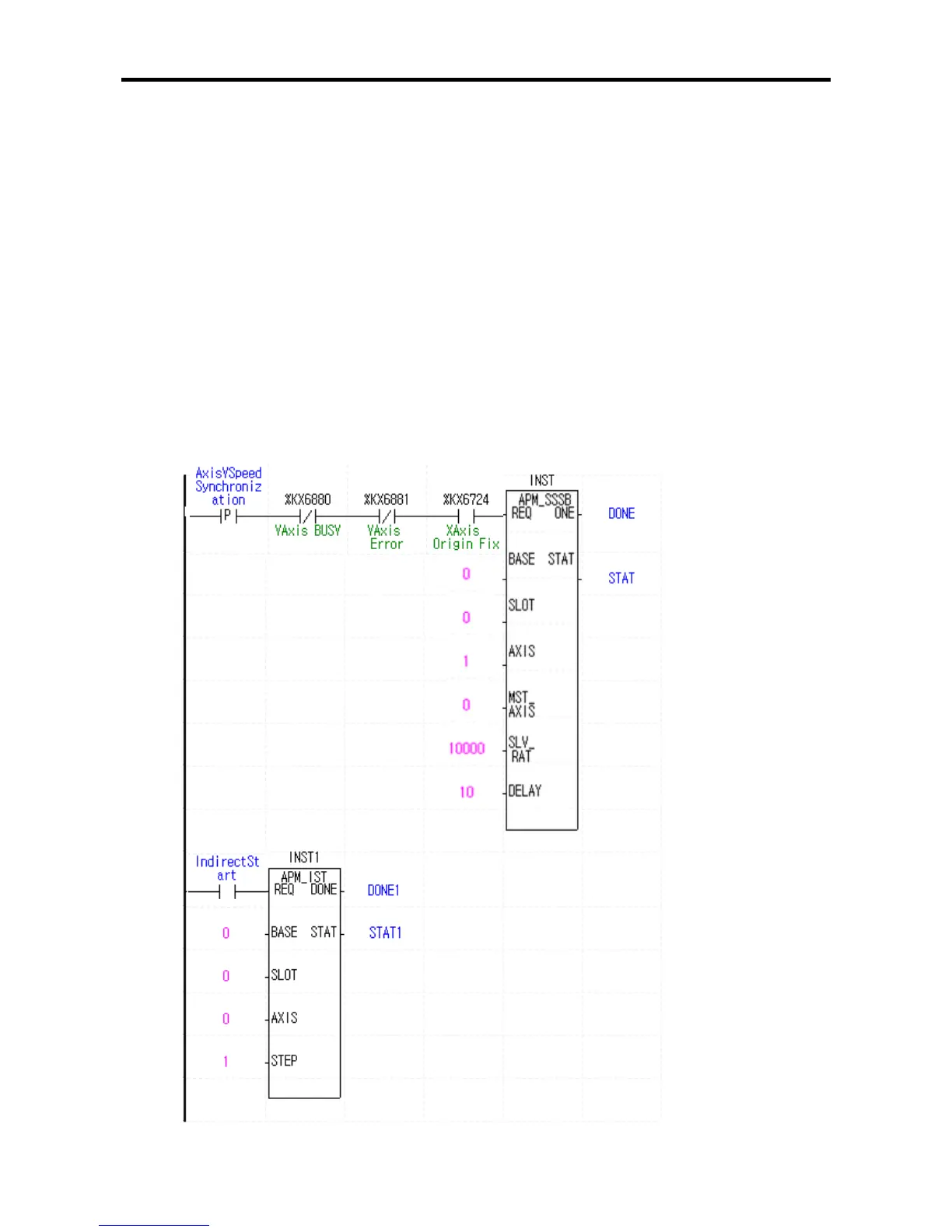

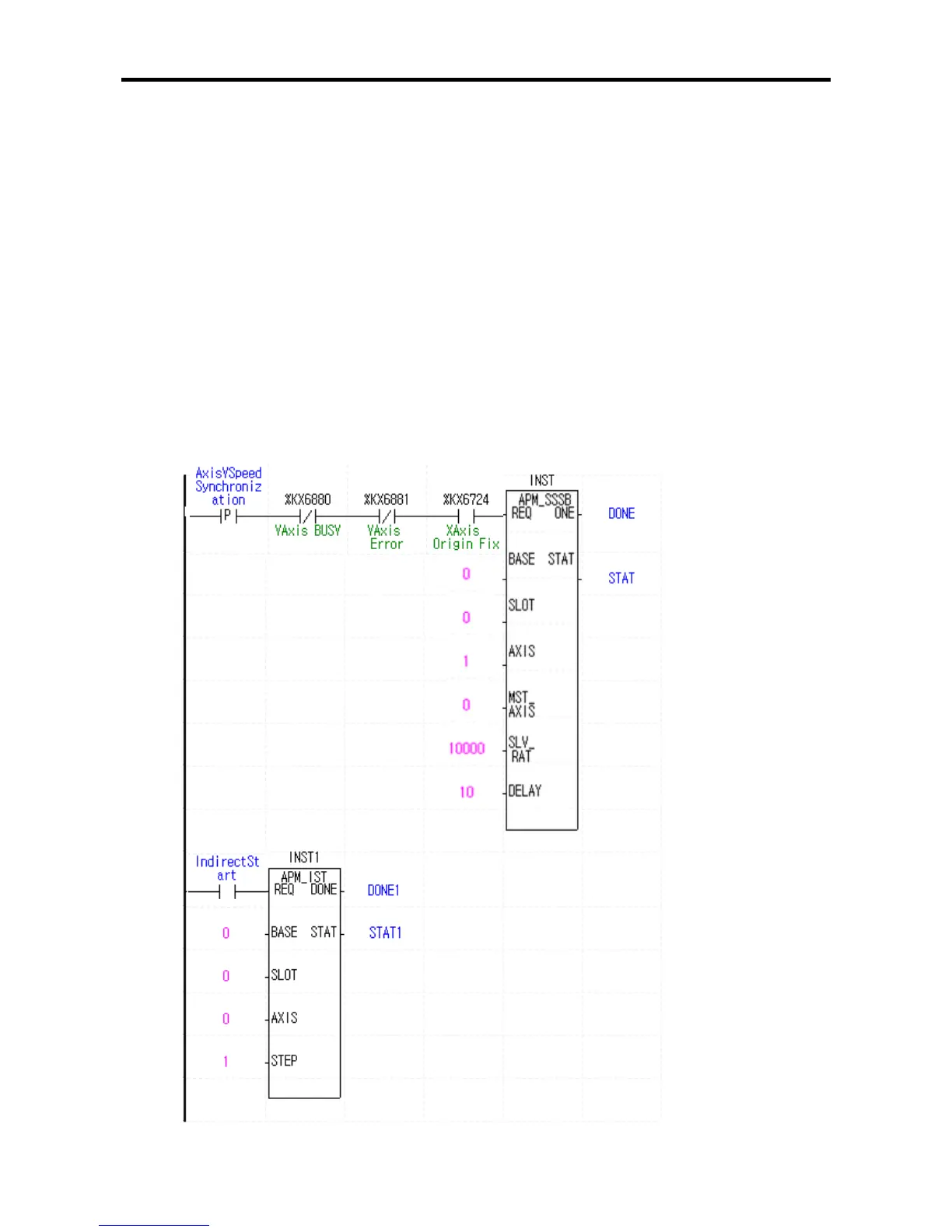

(2) Sample Instruction

•The program below is to show exemplary operation of speed synchronization start instruction.

(a) Sample Program

•In the sample program below with the Y-axis as the sub-axis and the X-axis as the main axis, the

speed synchronization start-up is executed at the synchronization ratio of

100.00[%] and delay time of 10[㎳] when the main axis is started-up.

Loading...

Loading...