MAN B&W 5.03

Page of 3

MAN Diesel

MAN B&W S90MC-C/ME-C7/8, S80MC-C/ME-C7 198 44 93-9.3

Crane beam for overhaul of turbocharger

For the overhaul of a turbocharger, a crane beam

with trolleys is required at each end of the turbo-

charger.

Two trolleys are to be available at the compressor

end and one trolley is needed at the gas inlet end.

Crane beam no. is for dismantling of turbo-

charger components.

Crane beam no. 2 is for transporting turbocharger

components.

See Figs. 5.03.0a and 5.03.02.

The crane beams can be omitted if the main en-

gine room crane also covers the turbocharger

area.

The crane beams are used and dimensioned for

lifting the following components:

• Exhaust gas inlet casing

• Turbocharger inlet silencer

• Compressor casing

• Turbine rotor with bearings

178 52 340.1

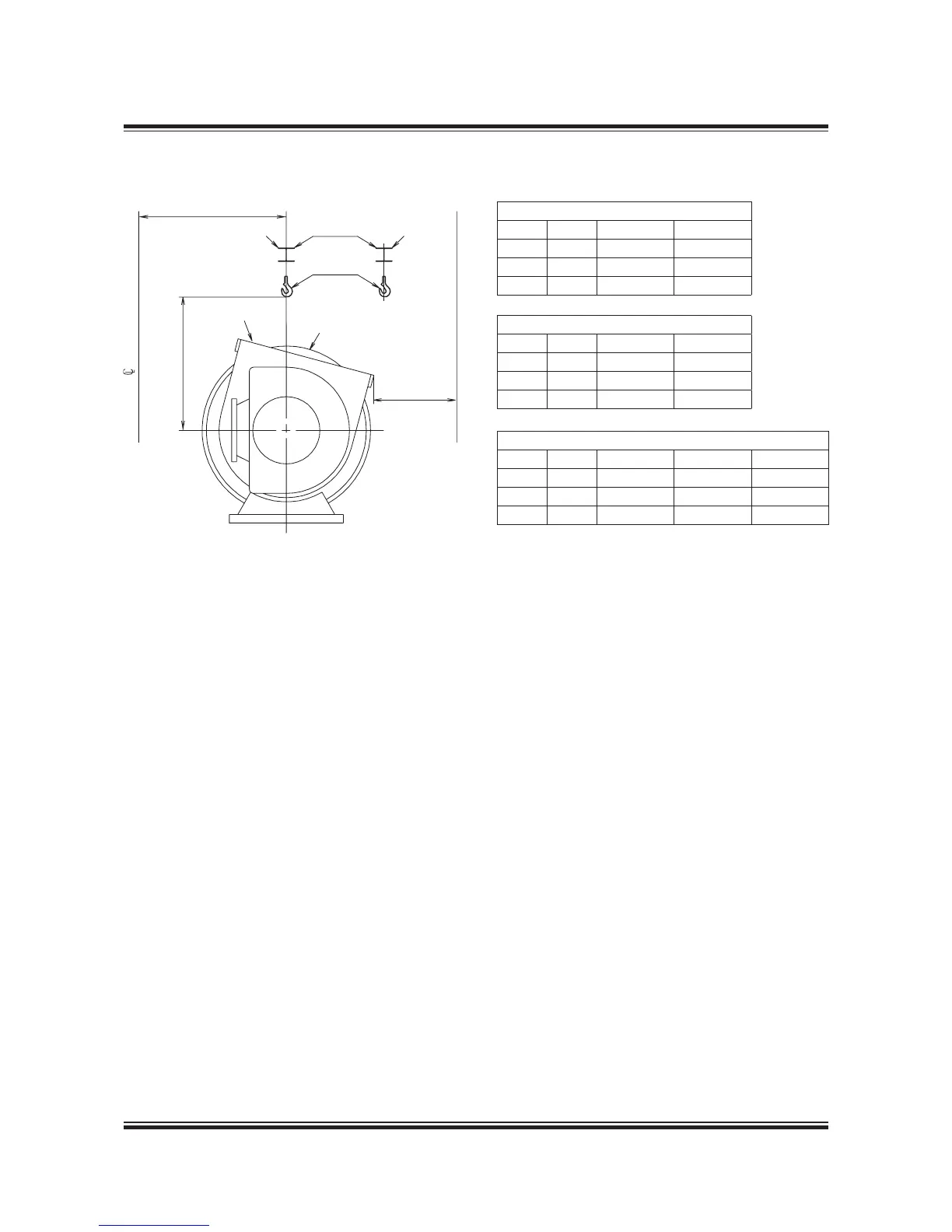

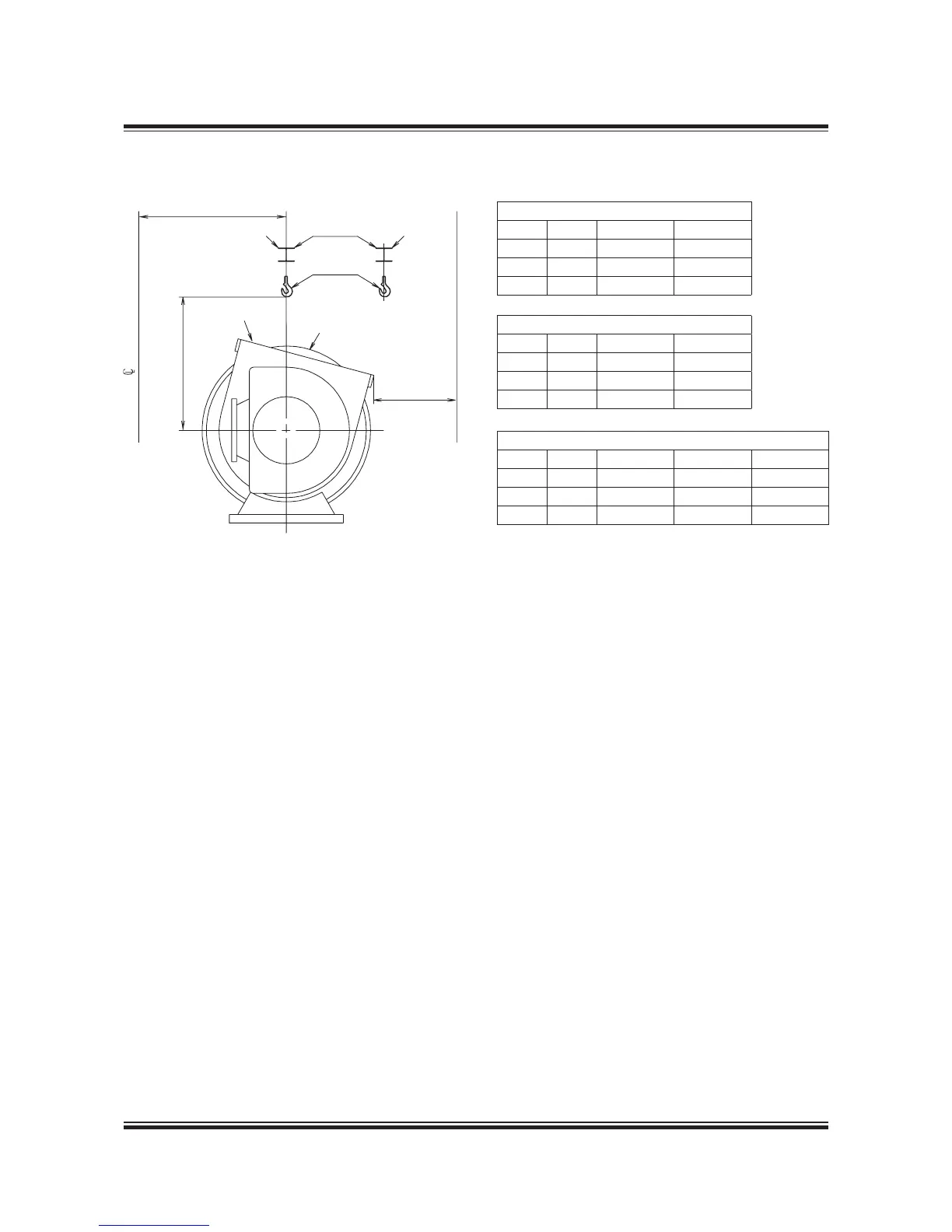

Fig. 5.03.01a: Required height and distance

The crane beams are to be placed in relation

to the turbocharger(s) so that the components

around the gas outlet casing can be removed in

connection with overhaul of the turbocharger(s).

The crane beam can be bolted to brackets that

are fastened to the ship structure or to columns

that are located on the top platform of the engine.

The lifting capacity of the crane beam for the

heaviest component ‘W’, is indicated in Fig.

5.03.0b for the various turbocharger makes. The

crane beam shall be dimensioned for lifting the

weight ‘W’ with a deection of some 5 mm only.

HB indicates the position of the crane hook in the

vertical plane related to the centre of the turbo-

charger. HB and b also species the minimum

space for dismantling.

For engines with the turbocharger(s) located on

the exhaust side, EoD No. 4 59 22, the letter

‘a’ indicates the distance between vertical cen-

trelines of the engine and the turbocharger.

Loading...

Loading...