MAN B&W 6.04

Page of 12

MAN Diesel

MAN B&W ME/MEC/MEGI engines 198 43 012.2

Freshwater Generator

If a freshwater generator is installed and is utilis-

ing the heat in the jacket water cooling system,

it should be noted that the actual available heat

in the jacket cooling water system is lower than

indicated by the heat dissipation gures valid for

nominal MCR (L

1

) given in the List of Capacities.

This is because the latter gures are used for

dimensioning the jacket water cooler and hence

incorporate a safety margin which can be needed

when the engine is operating under conditions

such as, e.g. overload. Normally, this margin is

10% at nominal MCR.

Calculation Method

For a derated diesel engine, i.e. an engine having

a specied MCR (M) and/or a matching point (O)

different from L

1

, the relative jacket water heat dis-

sipation for point M and O may be found, as previ-

ously described, by means of Fig. 6.04.02.

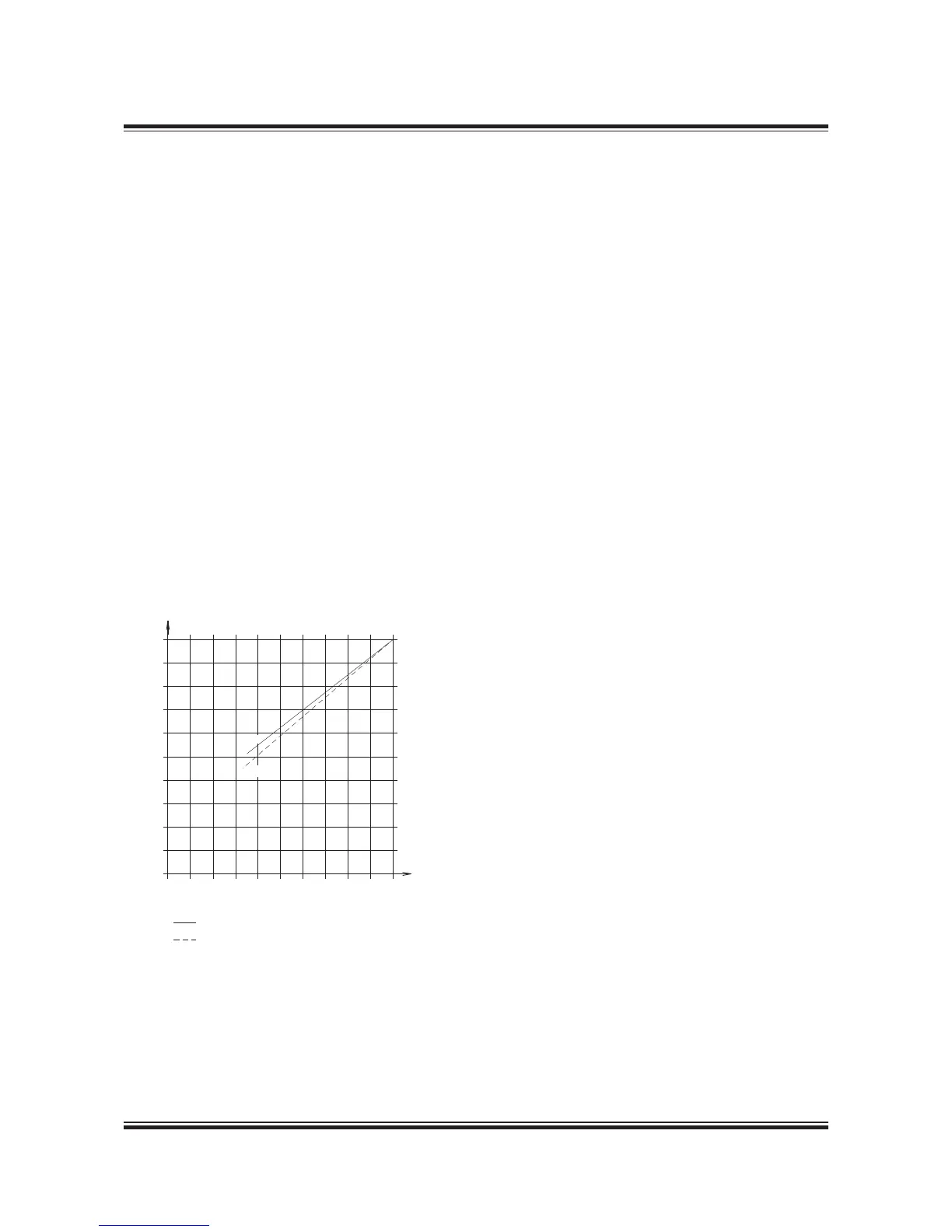

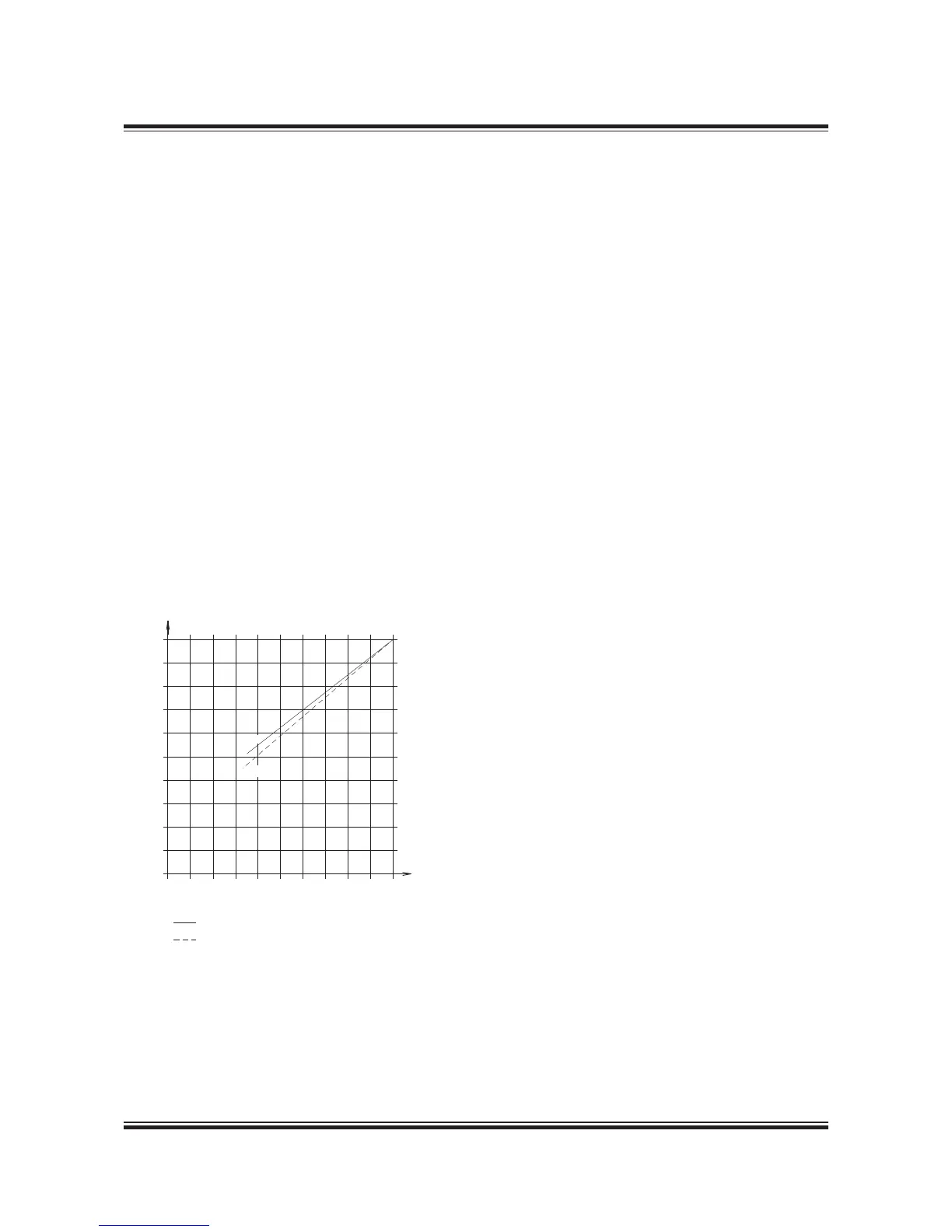

At part load operation, lower than matching pow-

er, the actual jacket water heat dissipation will be

reduced according to the curves for xed pitch

propeller (FPP) or for constant speed, controllable

pitch propeller (CPP), respectively, in Fig. 6.04.04.

With reference to the above, the heat actually

available for a derated diesel engine may then be

found as follows:

1. Engine power between matching and speci-

ed power.

For powers between specied MCR (M) and

matching power (O), the diagram Fig. 6.04.02

is to be used, i.e. giving the percentage cor-

rection factor ‘Q

jw%

’ and hence for matching

power P

O

:

Q

jw,O

= Q

jw,L1

x

Q

jw%

___

100

x 0.9 (0.88) [1]

2. Engine power lower than matching power.

For powers lower than the matching power,

the value Q

jw,O

found for point O by means of

the above equation [1] is to be multiplied by

the correction factor k

p

found in Fig. 6.04.04

and hence

Q

jw

= Q

jw,O

x k

p

1%/0% [2]

Part load correction factor for jacket

cooling water heat dissipation

Engine load, % of matching power (O)

FPP : Fixed pitch propeller

CPP : Controllable pitch propeller, constant speed

k

p

1.0

0.9

0.8

0.7

0.6

0.

0.4

0.3

0.2

0.1

0

0 10 20 30 40 0 60 70 80 90

100%

FPP

CPP

178 06 643.2

Fig. 6.04.04: Correction factor ‘kp’ for jacket cooling

water heat dissipation at part load, relative to heat dis-

sipation at matching power

FPP : k

p

= 0.742 x

P

S

__

P

O

+ 0.28

CPP : k

p

= 0.822 x

P

S

__

P

O

+ 0.178

where

Q

jw

= jacket water heat dissipation

Q

jw,L1

= jacket water heat dissipation at nominal

MCR (L

1

)

Q

jw%

= percentage correction factor from

Fig. 6.04.02

Q

jw,O

= jacket water heat dissipation at matching

power (O), found by means of equation [1]

k

p

= part load correction factor from Fig. 6.04.04

0.9 = factor for safety margin of cooler, tropical

ambient conditions

The heat dissipation is assumed to be more or less

independent of the ambient temperature conditions,

yet the safety margin/ambient condition factor of

about 0.88 instead of 0.90 will be more accurate for

ambient conditions corresponding to ISO tempera-

tures or lower. The heat dissipation tolerance from

1% to 0% stated above is based on experience.

Loading...

Loading...