K90ME, S80ME-C, S70ME-C/ME-GI, S60ME-C/ME-GI, S50ME-C 198 42 98-7.2

MAN B&W Diesel A/S 6.04

Page 1 of 12

Auxiliary Machinery Capacities

The dimensioning of heat exchangers (coolers) and

pumps for derated engines can be calculated on

the basis of the heat dissipation values found by

using the following description and diagrams. Those

for the nominal MCR (L

1

), may also be used if

wanted.

The nomenclature of the basic engine ratings and

coolers, etc. used in this section is shown in Fig.

6.01.01 and 6.01.02.

Cooler heat dissipations

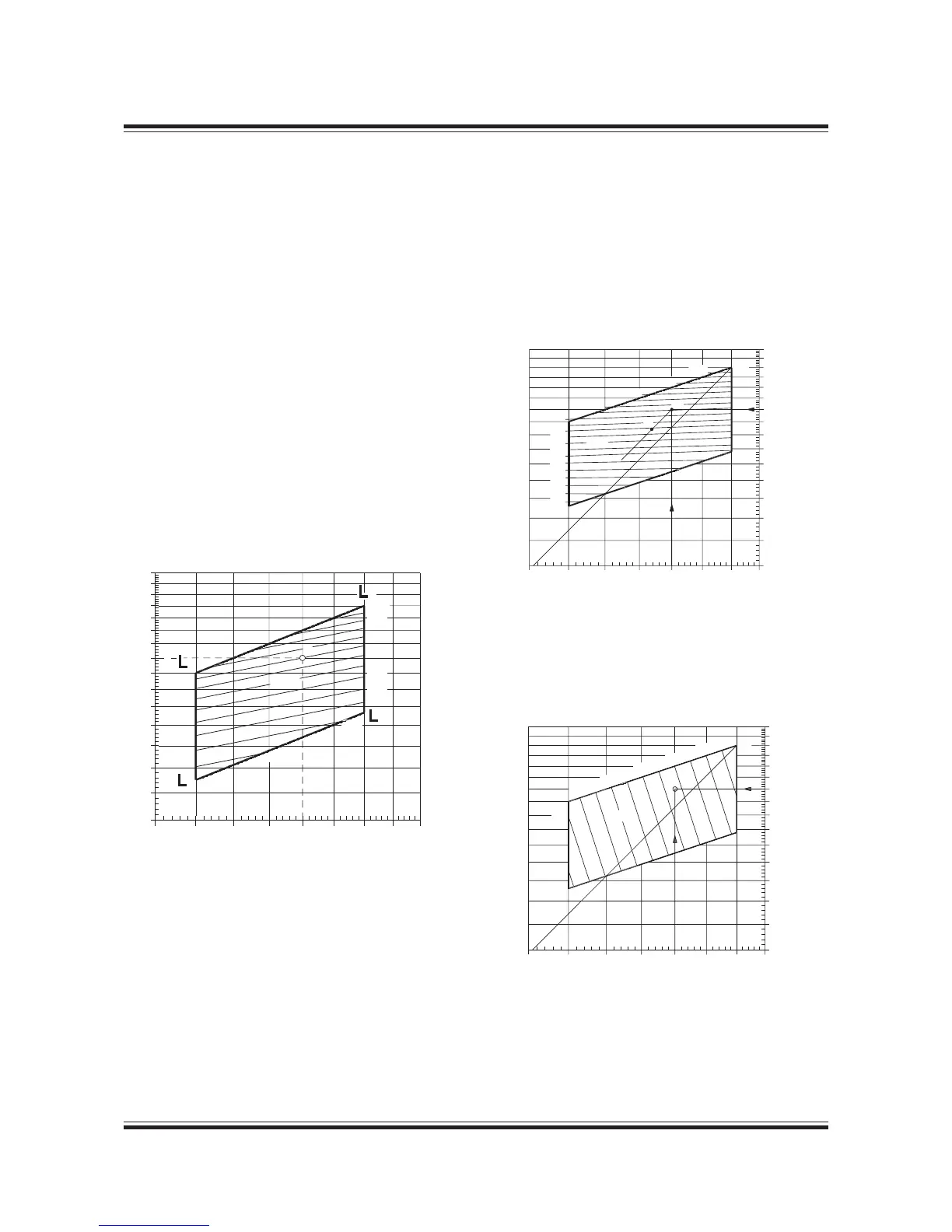

For the specified MCR (M) the following three dia-

grams in Figs. 6.04.01, 6.04.02 and 6.04.03 show re-

duction factors for the corresponding heat dissipa-

tions for the coolers, relative to the values stated in

the ‘List of Capacities’ valid for nominal MCR (L

1

).

3

4

2

1

M

Q

air%

40%

45%

100%

90%

80%

70%

60%

55%

50%

The percentage power (P

M%

) and speed (n

M%

) of L

1

ie: P

M%

= P

M

/P

L

1

x 100%

n

M%

= n

M

/n

L

1

x 100%

for specified MCR (M) of the derated engine is used

as input in the above-mentioned diagrams, giving

the % heat dissipation figures relative to those in

the ‘List of Capacities’,

Q

air%

= 100 x (P

M

/P

L1

)

1.68

x (n

M

/n

L1

)

– 0.83

x k

O

k

O

= 1 + 0.27 x (1 – P

O

/P

M

)

178 24 57-6.0

Fig. 6.04.01: Scavenge air cooler, heat dissipation Q

air%

in

point M, in % of the L

1

value Q

air, L

1

and valid for P

O

= P

M

.

If matching point O lower than M, an extra correction k

O

is used

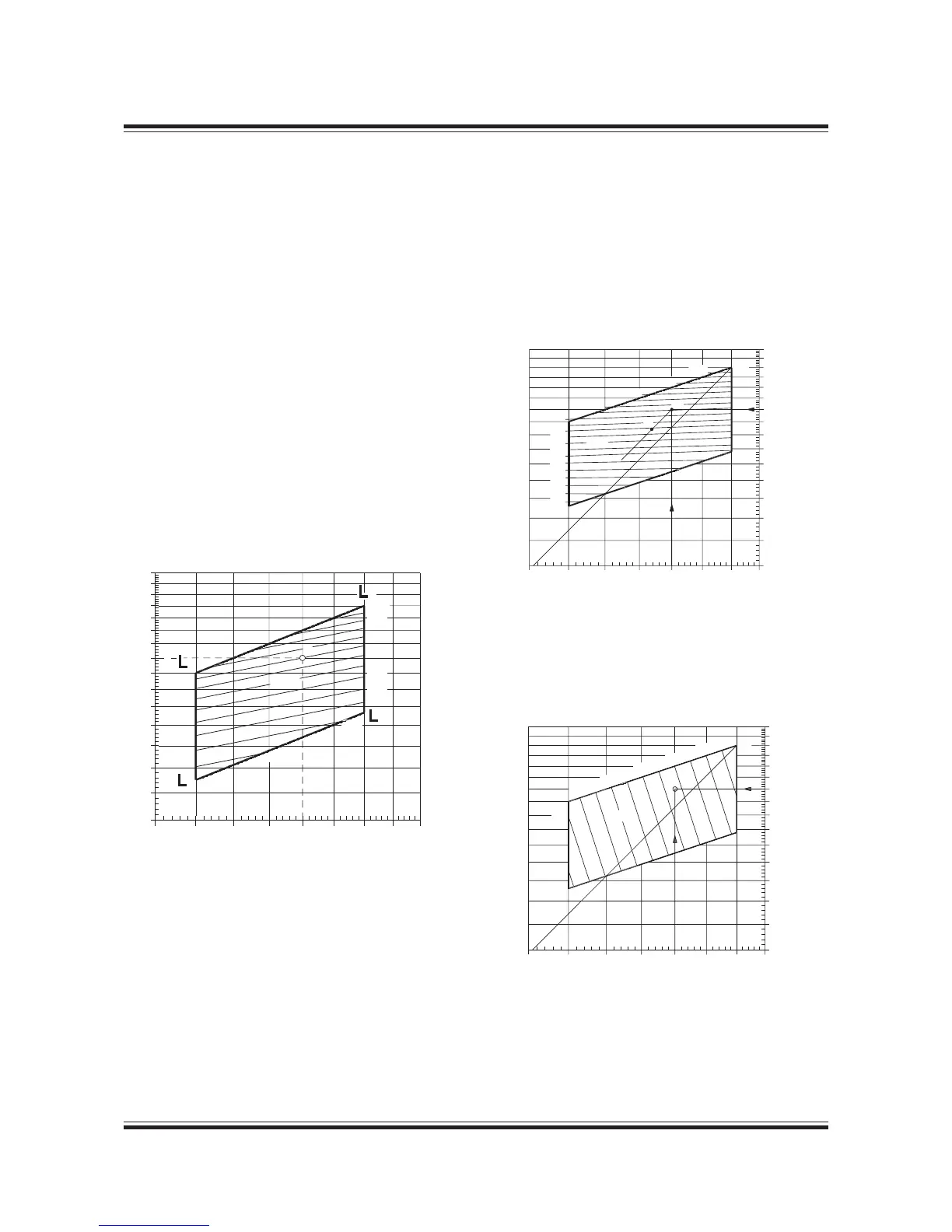

P

M%

110%

100%

90%

80%

70%

60%

50%

40%

Specified MCR

power, % af L

1

M

Q

lub%

78

76

80%

82%

84%

86%

88%

90%

92%

94%

96%

98%

L

1

Q

jw%

= e

(– 0.0811 x ln (n

M%

)

+ 0.8072 x ln (P

M%

) + 1.2614)

Fig. 6.04.02: Jacket water cooler, heat dissipation Q

jw%

in

point M, in% of the L

1

value Q

jw, L

1

178 50 16-0.0

Q

lub%

= 67.3009 x ln (n

M%

) + 7.6304 x ln (P

M%

)

- 245.0714

Fig. 6.04.03: Lubricating oil cooler, heat dissipation Q

lub%

in poiunt M, in % of the L

1

value Q

lub, L

1

178 08 07-7.1

Loading...

Loading...