MAN B&W 14.05

Page of

MAN Diesel

MAN B&W S80MC-C7/8, S80MEC7/8 198 40 220.2

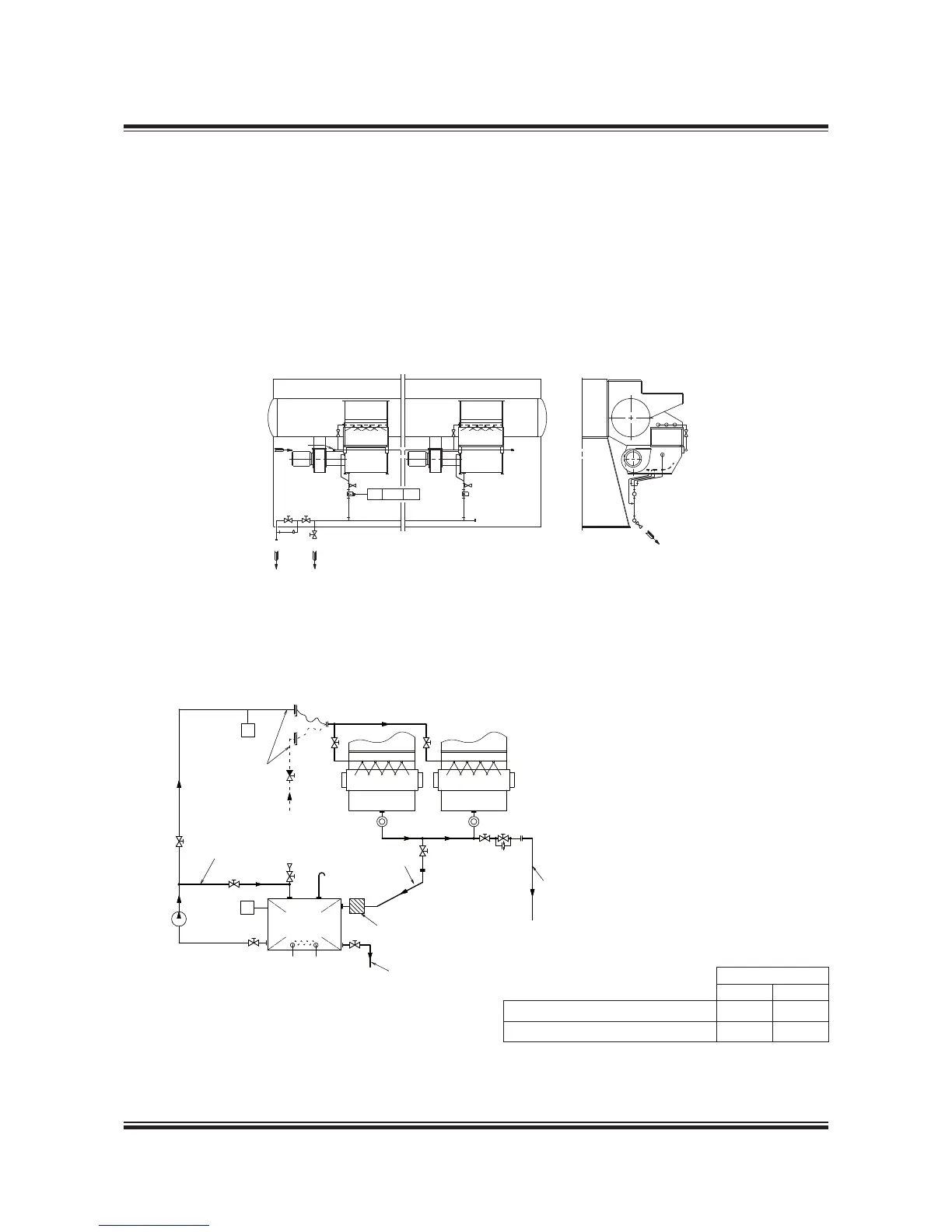

The air side of the scavenge air cooler can be

cleaned by injecting a grease dissolvent media

through ‘AK’ to a spray pipe arrangement tted to

the air chamber above the air cooler element.

Sludge is drained through ‘AL’ to the bilge tank

and the polluted grease dissolvent returns from

‘AM’ through a lter, to the chemical cleaning

tank. The cleaning must be carried out while the

engine is at standstill. The piping delivered with

and tted on the engine is shown in Fig 4.05.0

‘Air cooler cleaning pipes’.

The letters refer to list of ‘Counteranges‘

The item no refer to ‘Guidance values automation’

178 50 601.1

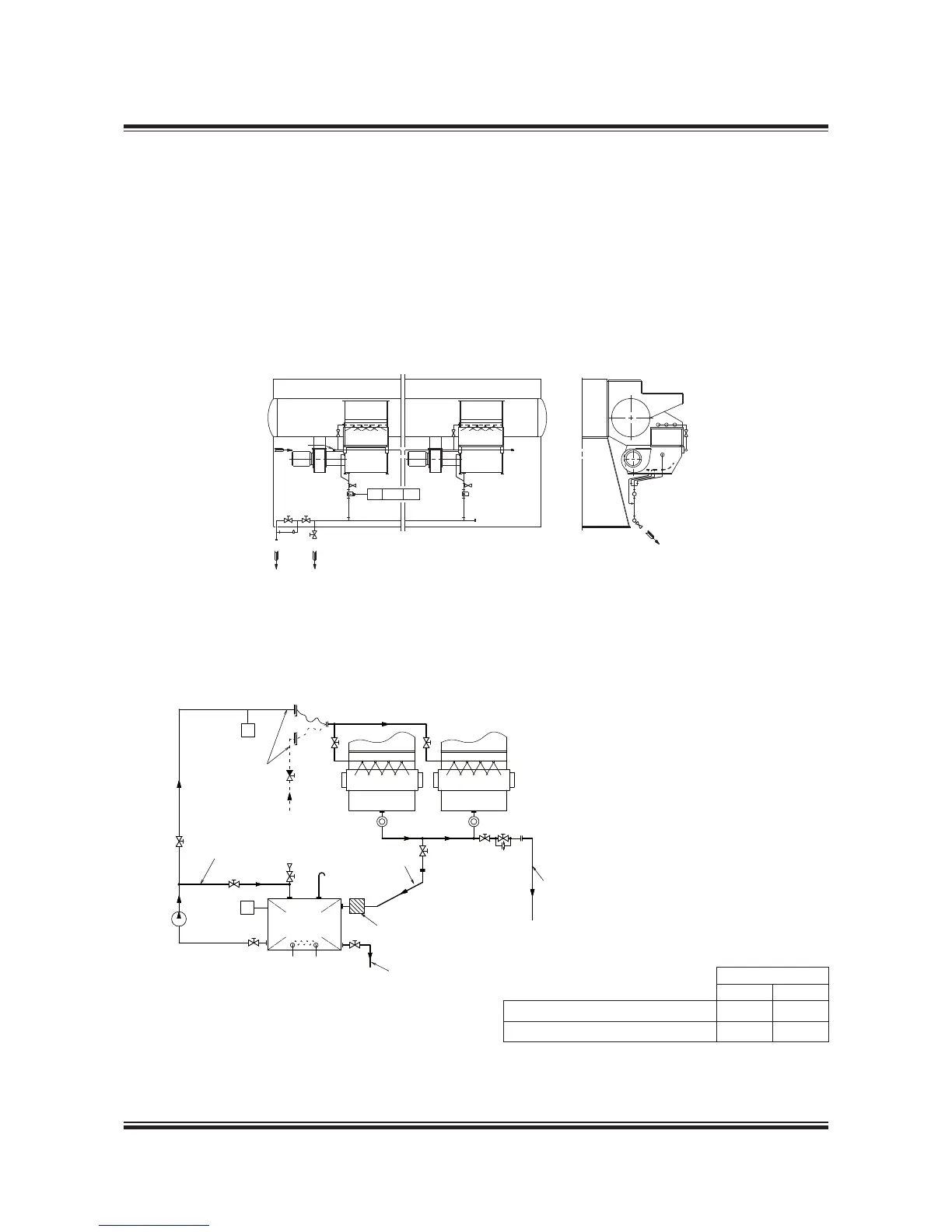

Fig. 14.05.01: Air cooler cleaning pipes

079 61 05-4.1.0a

The letters refer to list of ‘Counteranges‘

Fig. 14.05.02: Air cooler cleaning system

Scavenge Air Cooler Cleaning System

No. of cylinders

6 7-8

Chemical tank capacity 0.6 m

3

0.9 m

3

Circulation pump capacity at 3 bar 2 m

3

/h 3 m

3

/h

Air Cooler Cleaning Unit, option: 4 55 665

Loading...

Loading...