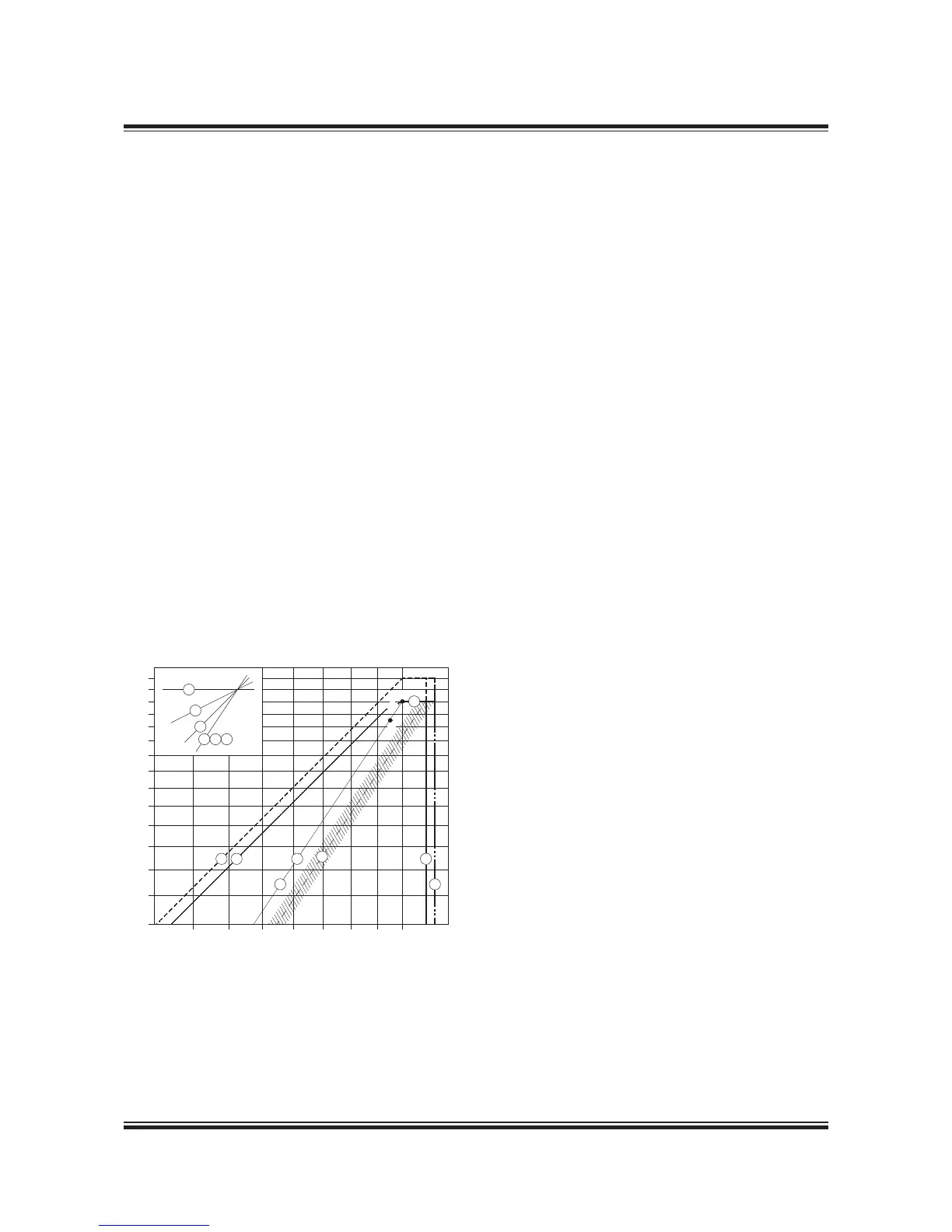

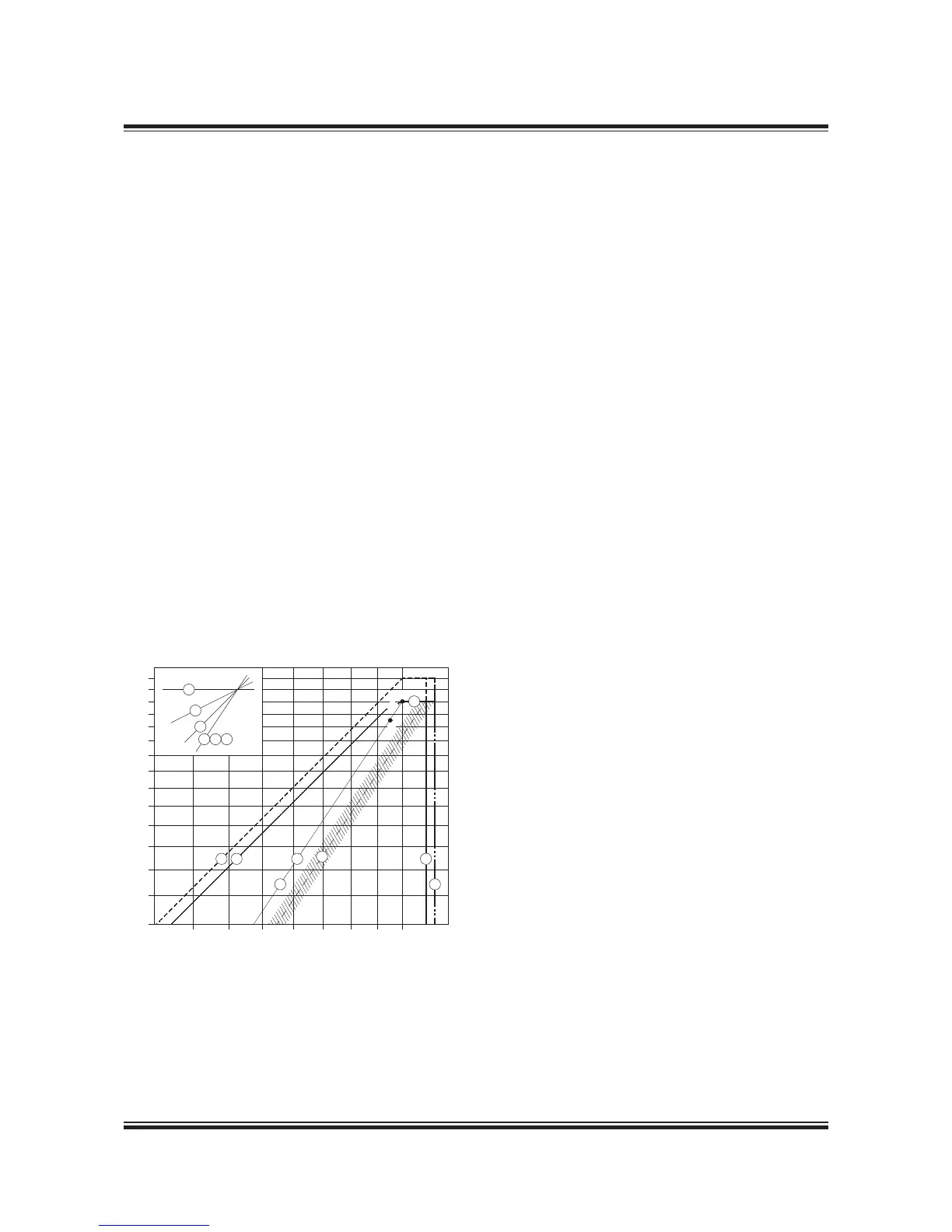

A 00% reference point

M Specied MCR

O Matching point

Fig. 2.04.02: Standard engine load diagram

Regarding ‘i’ in the power function P = c x n

i

, see page 2.0

178 05 427.3

Engine Load Diagram

Denitions

The engine’s load diagram denes the power and

speed limits for continuous as well as overload

operation of an installed engine having a specied

MCR point M that conrms the ship’s specication.

Point A is a 00% speed and power reference

point of the load diagram, and is dened as the

point on the propeller curve (line ), the layout

curve of the engine through the matching point

O, having the specied MCR power. Normally,

point M is equal to point A, but in special cases,

for example if a shaft generator is installed, point

M may be placed to the right of point A on line 7.

However, MAN Diesel may always consider point

A as the engine’s MCR for shop test.

In most cases, the points M and A are identical.

The service points of the installed engine incorpo-

rate the engine power required for ship propulsion

and shaft generator, if installed.

Operating curves and limits for continuous

operation

The continuous service range is limited by four

lines:

4, 5, 7 and 3 (9), see Fig. 2.04.02. The propeller

curves, line , 2 and 6 in the load diagram are also

described below.

Line 1:

Propeller curve through specied MCR (M), en-

gine layout curve (i = 3).

Line 2:

Propeller curve, fouled hull and heavy weather

– heavy running (i = 3).

Line 3 and line 9:

Line 3 represents the maximum acceptable speed

for continuous operation, i.e. 05% of A.

During trial conditions the maximum speed may

be extended to 07% of A, see line 9.

The above limits may in general be extended to

05% and during trial conditions to 07% of the

nominal L

speed of the engine, provided the tor-

sional vibration conditions permit.

The overspeed setpoint is 09% of the speed

in A, however, it may be moved to 09% of the

nominal speed in L

, provided that torsional vibra-

tion conditions permit.

Running at low load above 00% of the nominal L

speed of the engine is, however, to be avoided for

extended periods. Only plants with controllable

pitch propellers can reach this light running area.

Line 4:

Represents the limit at which an ample air supply

is available for combustion and imposes a limita-

tion on the maximum combination of torque and

speed (i = 2).

Line 5:

Represents the maximum mean effective pressure

level (mep), which can be accepted for continuous

operation (i = ).

Loading...

Loading...