MAN B&W 7.05

Page of

MAN Diesel

MAN B&W S90MEC, S80MEC, K80MEC 198 41 179.0

Fuel oil lter

The lter can be of the manually cleaned duplex

type or an automatic lter with a manually cleaned

bypass lter.

If a double lter (duplex) is installed, it should

have sufcient capacity to allow the specied full

amount of oil to ow through each side of the lter

at a given working temperature with a max. 0.

bar pressure drop across the lter (clean lter).

If a lter with backushing arrangement is

installed, the following should be noted. The re-

quired oil ow specied in the ‘List of capacities’,

i.e. the delivery rate of the fuel oil supply pump

and the fuel oil circulating pump, should be in-

creased by the amount of oil used for the back-

ushing, so that the

fuel oil pressure at the inlet to the main engine can

be maintained during cleaning.

In those cases where an automatically cleaned

lter is installed, it should be noted that in order

to activate the cleaning process, certain makers

of lters require a greater oil pressure at the inlet

to the lter than the pump pressure specied.

Therefore, the pump capacity should be adequate

for this purpose, too.

The fuel oil lter should be based on heavy fuel oil

of: 10 cSt at 80 °C = 700 cSt at 50 °C = 7000 sec

Redwood I/100 °F.

Fuel oil ow .........................see ‘List of capacities’

Working pressure .......................................... 10 bar

Test pressure ...................... according to class rule

Absolute neness .......................................... 50 µm

Working temperature .................. maximum 150 °C

Oil viscosity at working temperature ............15 cSt

Pressure drop at clean lter ........maximum 0. bar

Filter to be cleaned at a pressure

drop at ........................................maximum 0.5 bar

Note:

Absolute neness corresponds to a nominal ne-

ness of approximately 30 µm at a retaining rate of

90%.

The lter housing shall be tted with a steam jack-

et for heat tracing.

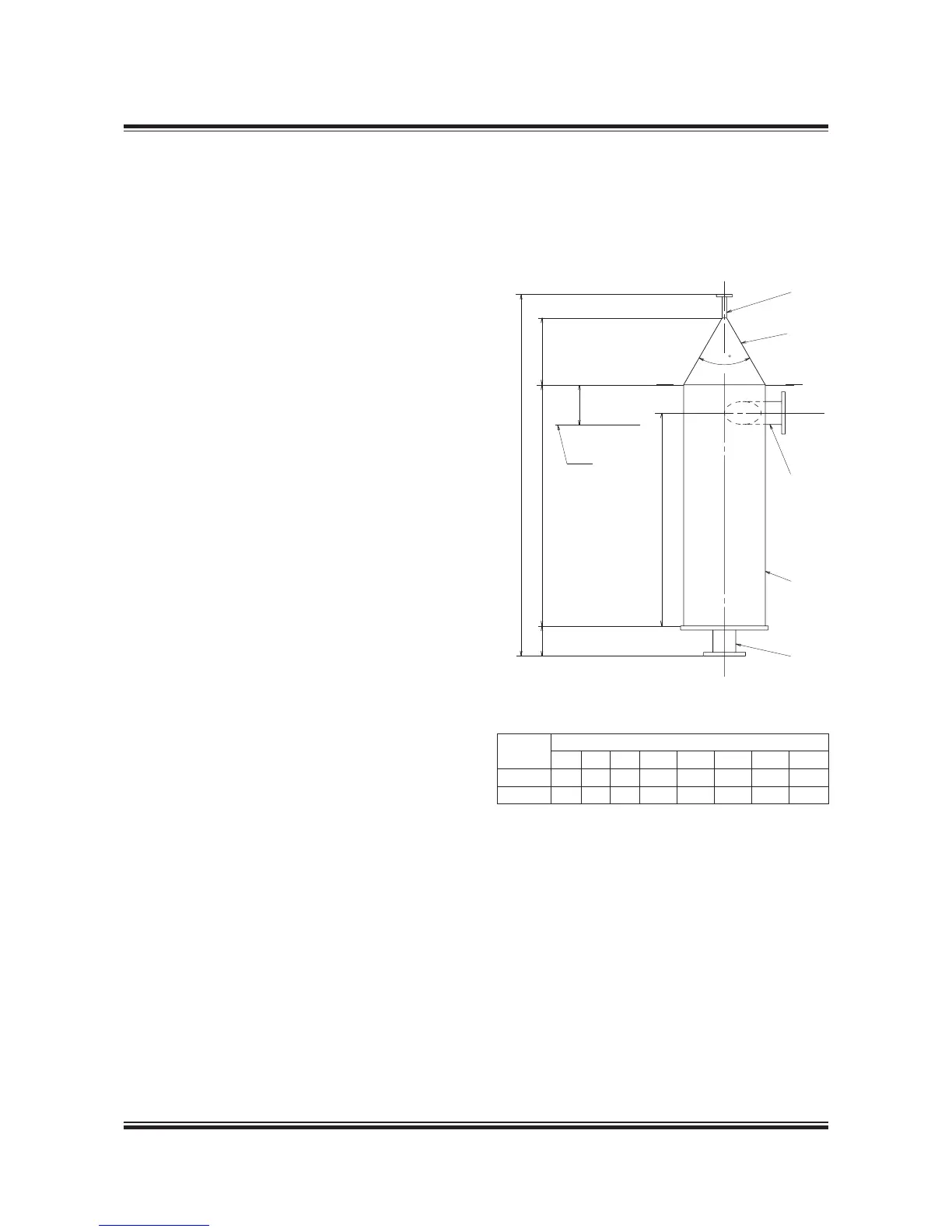

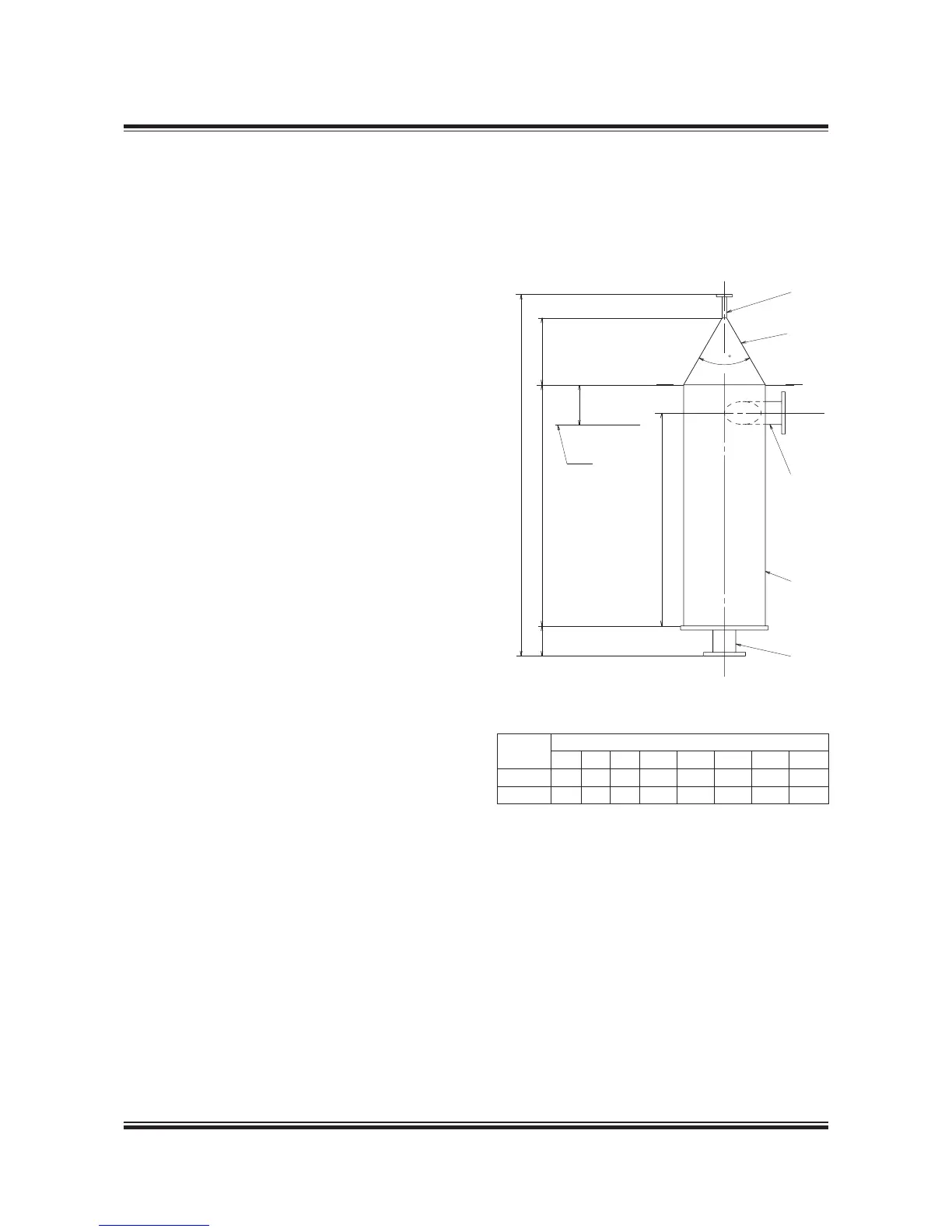

Fuel oil venting box

The design is shown on ‘Fuel oil venting box’, see

Fig. 7.05.02

Flow m

/h Dimensions in mm

Q (max.)* D1 D2 D H1 H2 H H4 H5

11.5 400 90 15 150 1,200 .5 1,800 1,100

19.5 400 125 15 150 1,200 .5 1,800 1,100

Fig. 07.05.02: Fuel oil venting box

Flushing of the fuel oil system

Before starting the engine for the rst time, the

system on board has to be ushed in accordance

with MAN B&W’s recommendations ‘Flushing of

Fuel Oil System’ which is available on request.

* The actual maximum ow of the fuel oil circulation pump

178 38 393.2

Loading...

Loading...