MAN B&W 15.01

Page of

MAN Diesel

MAN B&W K108MEC6, K98MC/ME6/7, K98MC-C/MEC6/7,

S90MC-C/MEC7/8, K90MC-C/ME-C6, K90ME/MEC9, S80MC6,

S80MC-C7/8, S80MEC7/8/9, K80MC-C6, K80MEC6/9, S70MC6,

S70MC-C/MEC/MEGI7/8, L70MC-C/MEC7/8

198 40 472.3

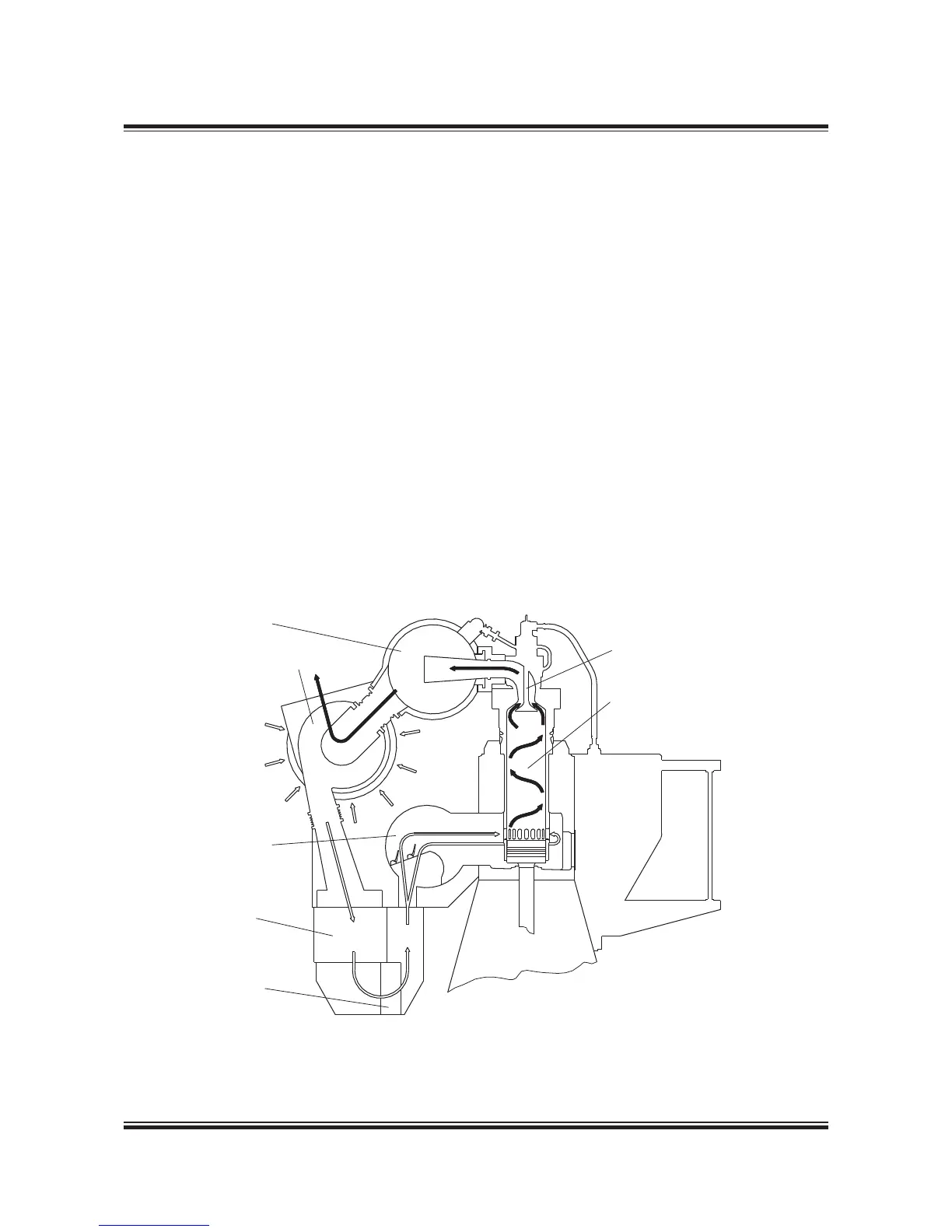

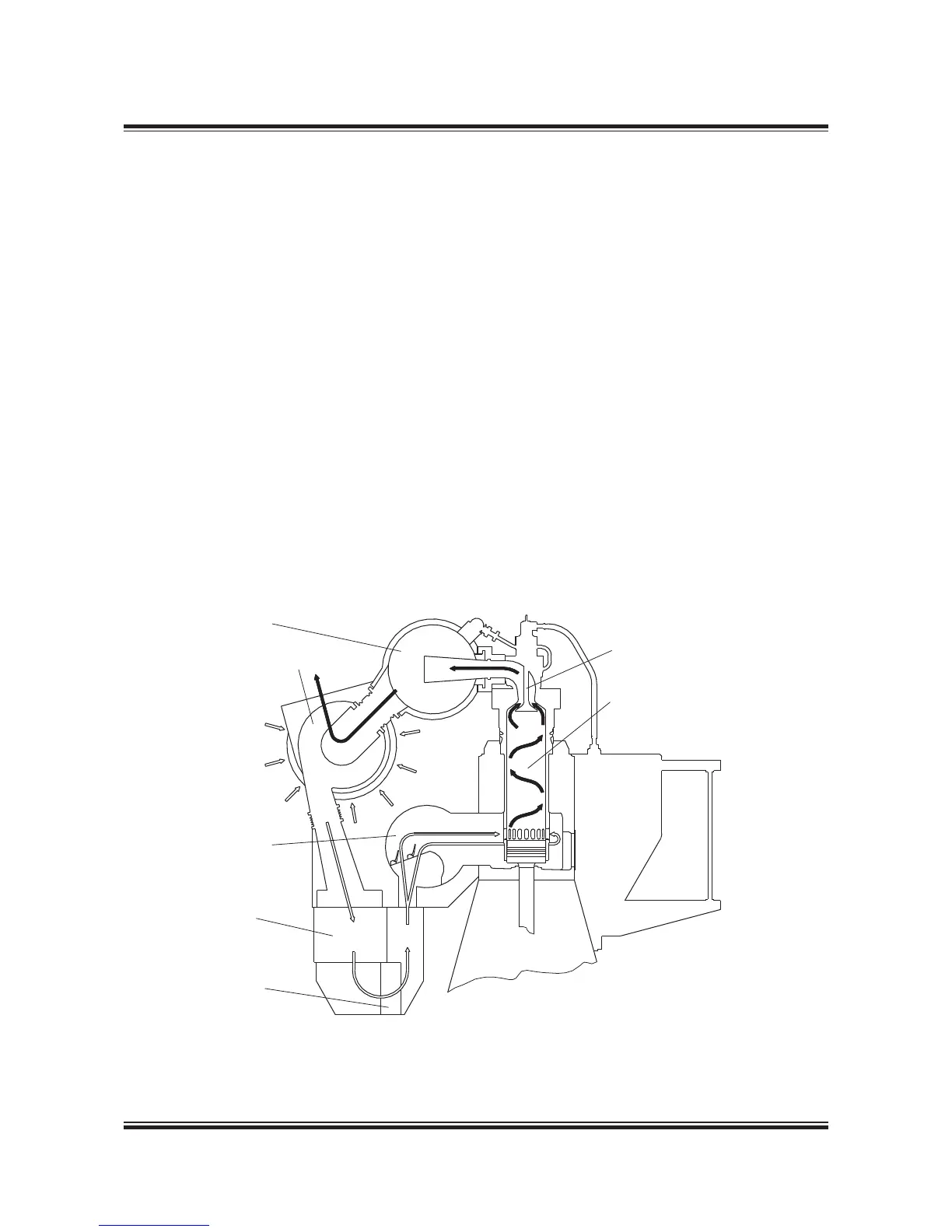

Exhaust Gas System

The exhaust gas is led from the cylinders to the

exhaust gas receiver where the uctuating pres-

sures from the cylinders are equalised and from

where the gas is led further on to the turbocharger

at a constant pressure. See g. 5.0.0.

Compensators are tted between the exhaust

valve housings and the exhaust gas receiver and

between the receiver and the turbocharger. A pro-

tective grating is placed between the exhaust gas

receiver and the turbocharger. The turbocharger

is tted with a pickup for monitoring and remote

indication of the turbocharger speed.

The exhaust gas receiver and the exhaust pipes

are provided with insulation, covered by steel

plating.

Turbocharger arrangement and cleaning systems

The turbochargers are located on the exhaust

side of the engine.

The engine is designed for the installation of the

MAN Diesel turbocharger types TCA (4 59 0),

ABB turbocharger type TPL (4 59 02), or MHI tur-

bocharger type MET (4 59 03).

All makes of turbochargers are tted with an ar-

rangement for water washing of the compressor

side, and soft blast cleaning of the turbine side,

see Figs. 5.02.02, 5.02.03 and 5.02.04. Wash-

ing of the turbine side is only applicable on MAN

Diesel and ABB turbochargers.

178 07 274.1

Fig. 15.01.01: Exhaust gas system on engine

Loading...

Loading...