MAN B&W 2.04

Page of

MAN Diesel

MAN B&W ME/ME-C/ME-GI engines

198 38 97-3.6

Example 6:

Engines running at constant speed with con-

trollable pitch propeller (CPP)

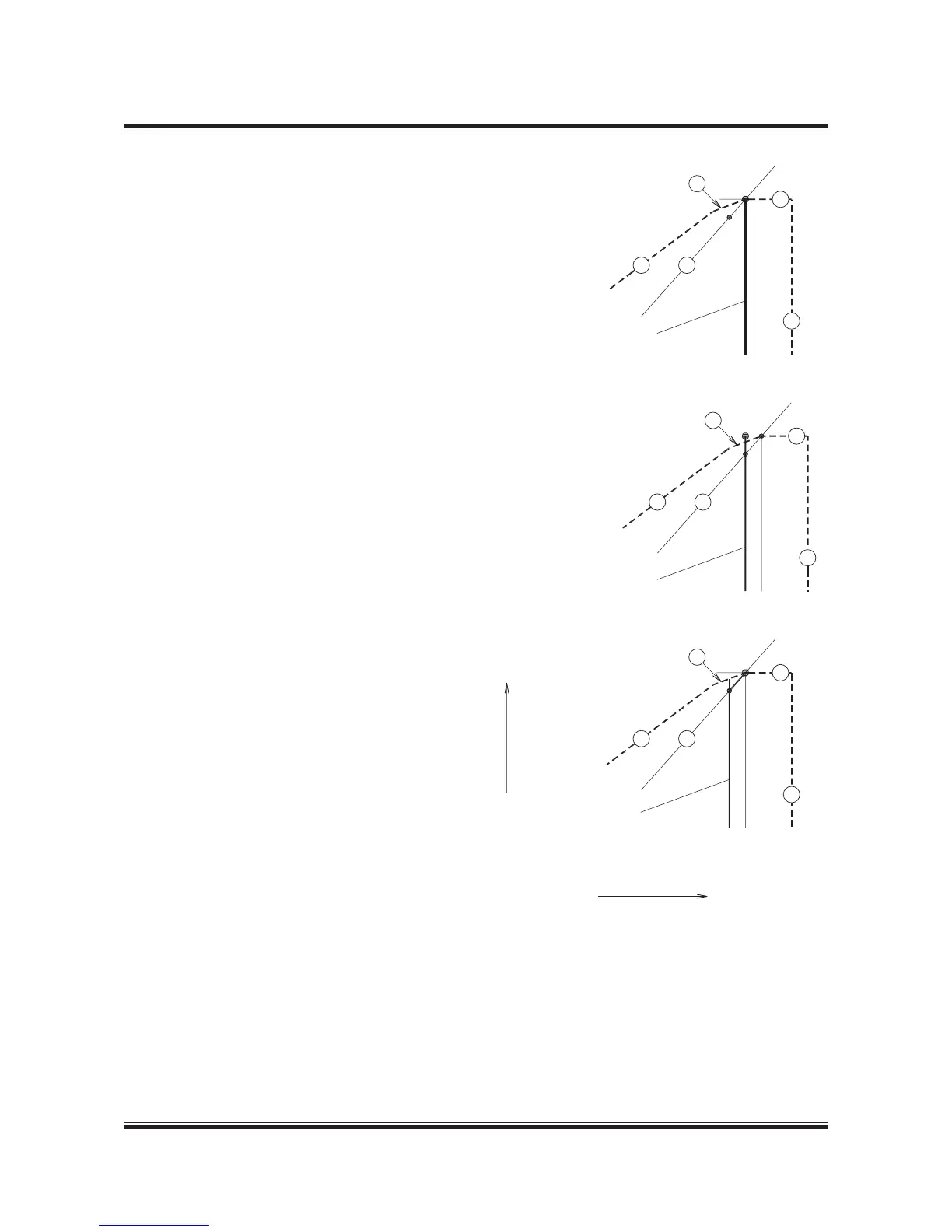

Fig. A Constant speed curve through M, normal

and correct location of the matching point O

Irrespective of whether the engine is operating on

a propeller curve or on a constant speed curve

through M, the matching point O must be located

on the propeller curve through the specied MCR

point M or, in special cases, to the left of point M.

The reason is that the propeller curve through

the matching point O is the layout curve of the

engine, and the intersection between curve and

the maximum power line 7 through point M is

equal to 00% power and 00% speed, point A of

the load diagram in this case A=M.

In Fig. A the matching point O has been placed

correctly, and the stepup gear and the shaft gen-

erator, if installed, may be synchronised on the

constant speed curve through M.

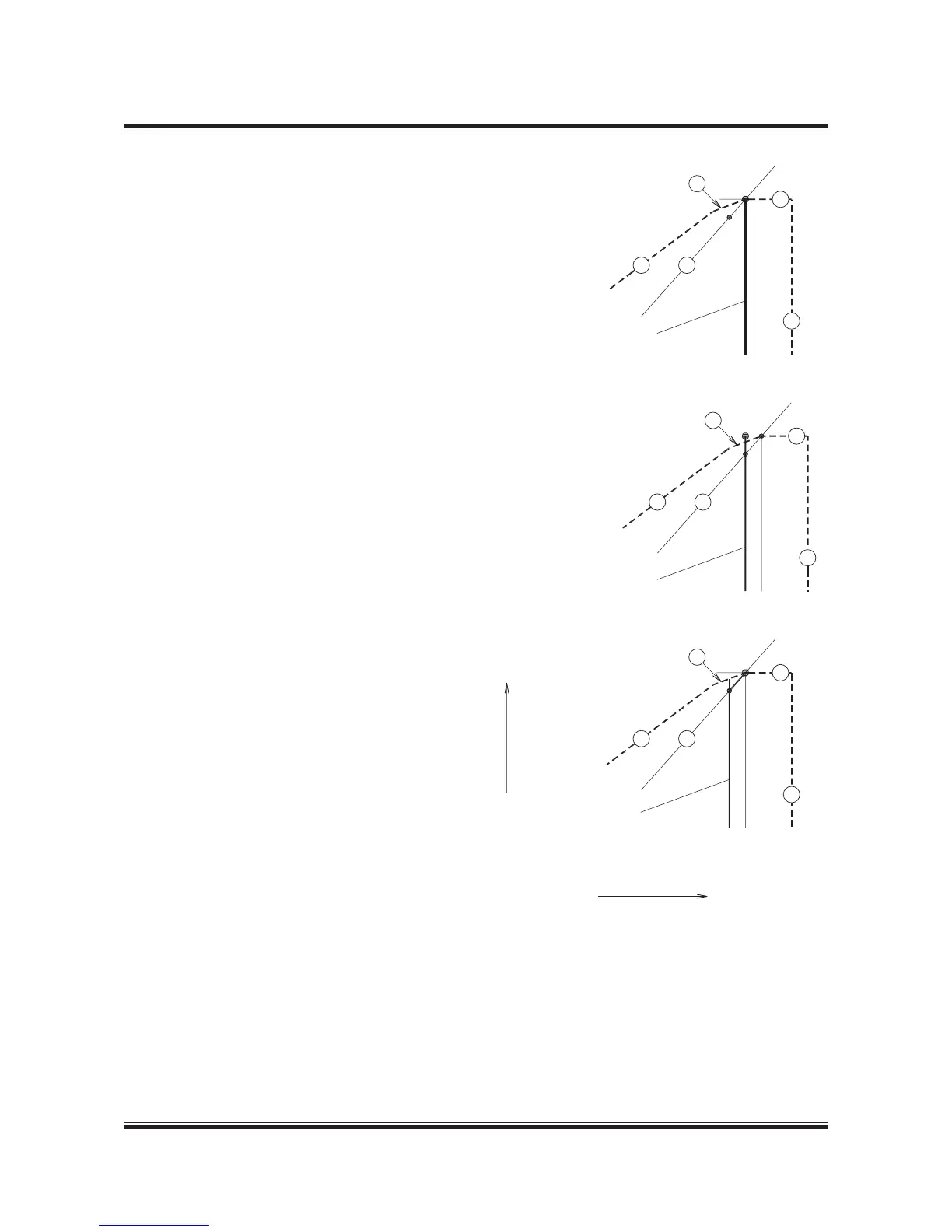

Fig. B: Constant speed curve through M, wrong

position of matching point O

If the engine has been servicematched at point O

on a constant speed curve through point M, then

the specied MCR point M would be placed out-

side the load diagram, and this is not permissible.

Fig. C: Recommended constant speed running

curve, lower than speed M

In this case it is assumed that a shaft generator,

if installed, is synchronised at a lower constant

main engine speed (for example with speed equal

to O or lower) at which improved CP propeller ef-

ciency is obtained for part load running.

In this layout example where an improved CP pro-

peller efciency is obtained during extended peri-

ods of part load running, the stepup gear and the

shaft generator have to be designed for the lower

constant engine speed that is applied.

Loading...

Loading...