S80ME-C 198 43 47-9.1

MAN B&W Diesel A/S 6.03

Page 1 of 3

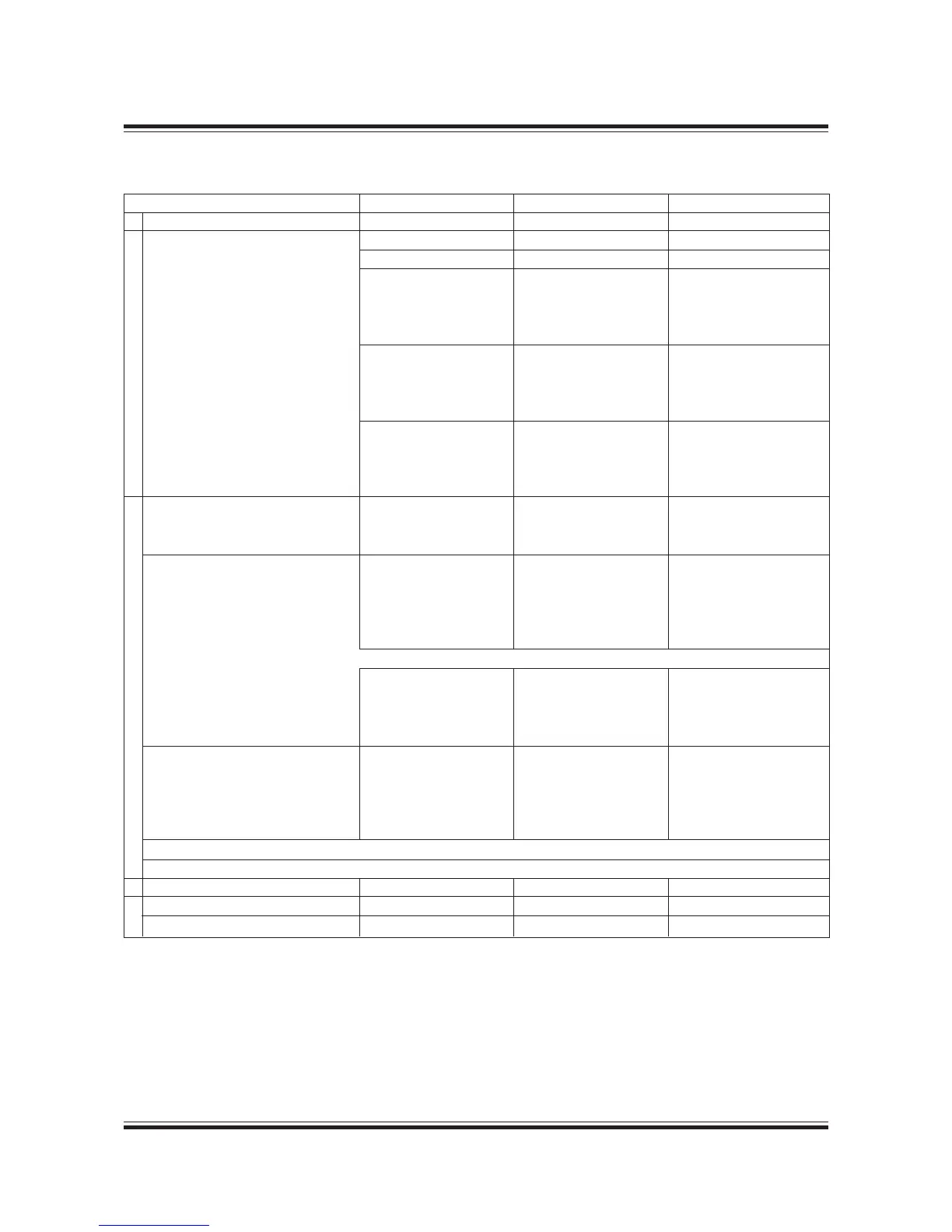

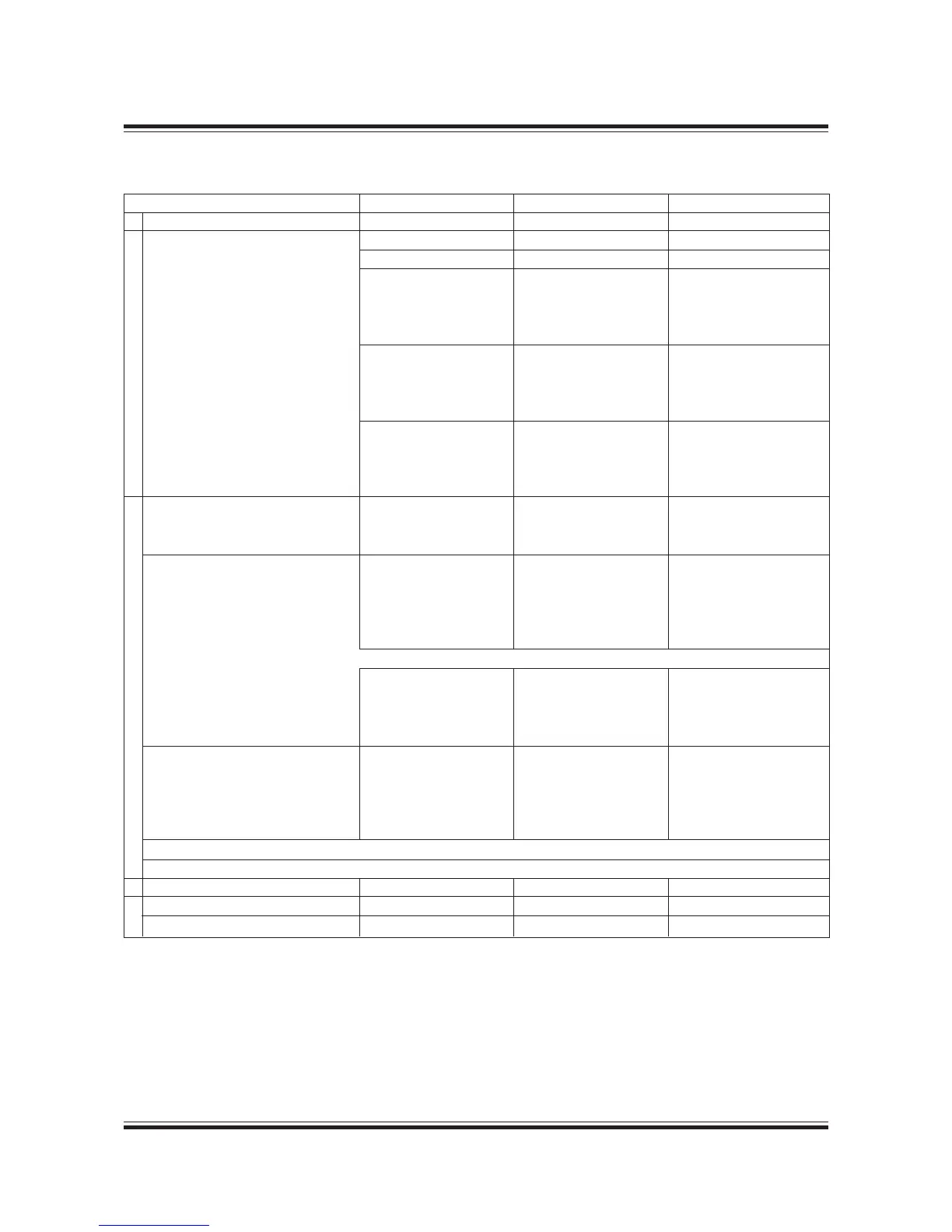

List of capacities, S80ME-C, High efficiency T/C and seawater cooling system

PumpsCoolers

* For main engine arrangements with built-on power take-off (PTO) of an MAN B&W recommended type and/or torsional vibration

damper the engine’s capacities must be increased by those stated for the actual system

** The exhaust gas amount and temperature must be adjusted according to the actual plant specification

1) Engines with MAN B&W turbochargers, type TCA 3) Engines with ABB turbochargers, type TPL

2) Engines with MAN B&W turbochargers, type NA 4) Engines with Mitsubishi turbochargers

Fig. 6.03.01: High efficiency turbocharger and seawater cooling system stated at the nominal MCR power (L

1

)

for engines complying with IMO’s NO

x

emission limitations

Cyl. 6 7 8

Nominal MCR at 76.0 r/min kW 23,280 27,160 31,040

Fuel oil circulating pump m

3

/h 9.1 10.7 12.2

Fuel oil supply pump m

3

/h 5.7 6.7 7.6

Jacket cooling pump m

3

/h 1) 200 230 265

2) 215 250 285

3) 200 230 265

4) 200 230 265

Seawater cooling pump* m

3

/h 1) 710 830 950

2) 730 840 960

3) 710 830 960

4) 710 830 950

Main lubricating oil pump* m

3

/h 1) 440 510 590

2) 445 520 590

3) 440 520 590

4) 440 510 590

Scavenge air cooler(s):

Heat dissipation approx. kW 9,160 10,690 12,210

Seawater flow m

3

/h 456 532 608

Lubricating oil cooler:

Heat dissipation approx.* kW 1) 1,750 2,090 2,410

2) 1,880 2,150 2,410

3) 1,810 2,130 2,510

4) 1,770 2,090 2,410

Lubricating oil flow* See above ‘Main lubricating oil pump’

Seawater flow m

3

/h 1) 254 298 342

2) 274 308 352

3) 254 298 352

4) 254 298 342

Jacket water cooler:

Heat dissipation approx. kW 1) 3,430 4,000 4,580

2) 3,590 4,160 4,730

3) 3,430 4,000 4,580

4) 3,430 4,000 4,580

Jacket cooling water flow See above ‘Jacket cooling water’

Seawater flow See above ‘Seawater quantity’

Fuel oil heater kW 240 280 320

Exhaust gas amount at 245º C** kg/h 216,000 252,000 288,000

Air consumption kg/h 58.9 68.7 78.6

Loading...

Loading...