MAN B&W 4.03

Page 3 of 6

MAN Diesel

198 43 156.2MAN B&W K108ME-C6, K98MC/MC-C/ME/ME-C6/7,

S90MC-C/ME-C7/8, K90ME/ME-C9, K90MC-C/ME-C6, S80MC6,

S80MC-C7/8, S80ME-C7/8/9, K80ME-C9, K80MC-C/ME-C6,

S70MCC/ME-C/ME-GI7/8, S70MC6, L70MCC/ME-C7/8,

S65ME-C/ME-GI8, S60MC6, S60MC-C/ME-C/ME-GI7/8,

L60MC-C/ME-C7/8, S50MC-C7/8, S50MC6, S50ME-B8/9

Crankshaft gear lubricated from the main engine lubricating oil system

The gures are to be added to the main engine capacity list:

Nominal output of generator kW 700 ,00 ,800 ,600

Lubricating oil ow m

3

/h 4. 4. 4.9 6.

Heat dissipation kW . 0.8 3. 45.0

RCF gear with separate lubricating oil system:

Nominal output of generator kW 700 ,00 ,800 ,600

Cooling water quantity m

3

/h 4. . 30.0 39.0

Heat dissipation kW 55 9 34 80

El. power for oil pump kW .0 5.0 8.0 .0

Dosage tank capacity m

3

0.40 0.5 0.69 0.95

El. power for Renkcontroller 4V DC ± 0%, 8 amp

From main engine:

Design lube oil pressure: .5 bar

Lube oil pressure at crankshaft gear: min. bar

Lube oil working temperature: 50 °C

Lube oil type: SAE 30

Fig. 4.03.02: Necessary capacities for PTO/RCF, BW III/RCF system

178 33 850.0

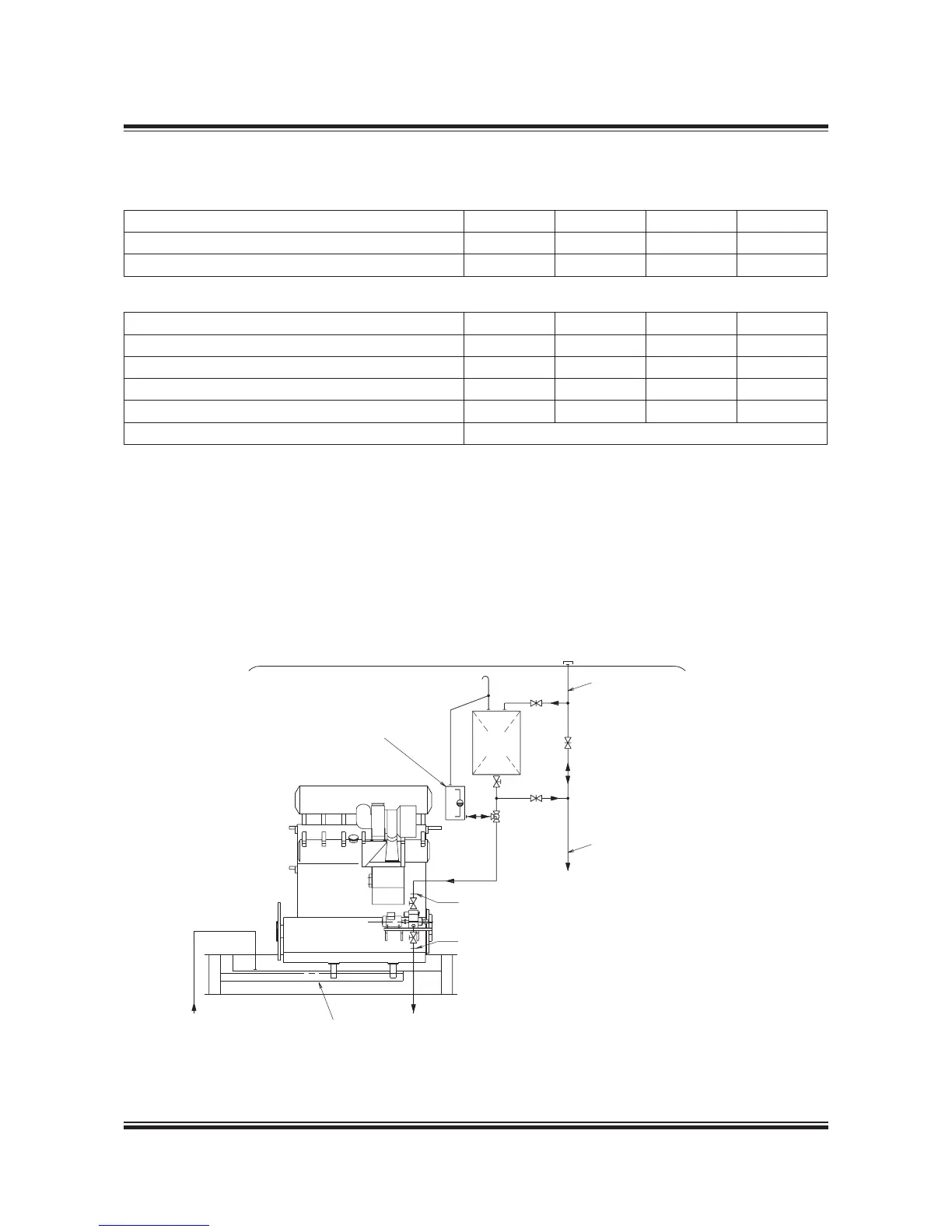

Cooling water inlet temperature: 36 °C

Pressure drop across cooler: approximately 0.5 bar

Fill pipe for lube oil system store tank (~ø3)

Drain pipe to lube oil system drain tank (~ø40)

Electric cable between Renk terminal at gearbox

and operator control panel in switchboard: Cable

type FMGCG 9 x x 0.5

The letters refer to the ‘List of anges’,

which will be extended by the engine builder,

when PTO systems are built on the main engine

Fig. 4.03.03: Lubricating oil system for RCF gear

178 25 235.0

Loading...

Loading...