The letters refer to list of ‘Counteranges’

* Venting for MAN B&W or Mitsubishi turbochargers only

198 99 844.4

The introduction of the ME engines has given rise

to the following modications:

• The camshaft has been omitted

• The mechanical type fuel pumps have been

replaced by the electronically controlled fuel

injection system

• A Hydraulic Power Supply (HPS) unit has been

introduced either mounted on the engine and en-

gine driven (EoD 440 60) or separately mounted

and electrically driven, option 4 40 660.

As a consequence, the main pipes for camshaft

lubrication and exhaust valve actuation have been

omitted.

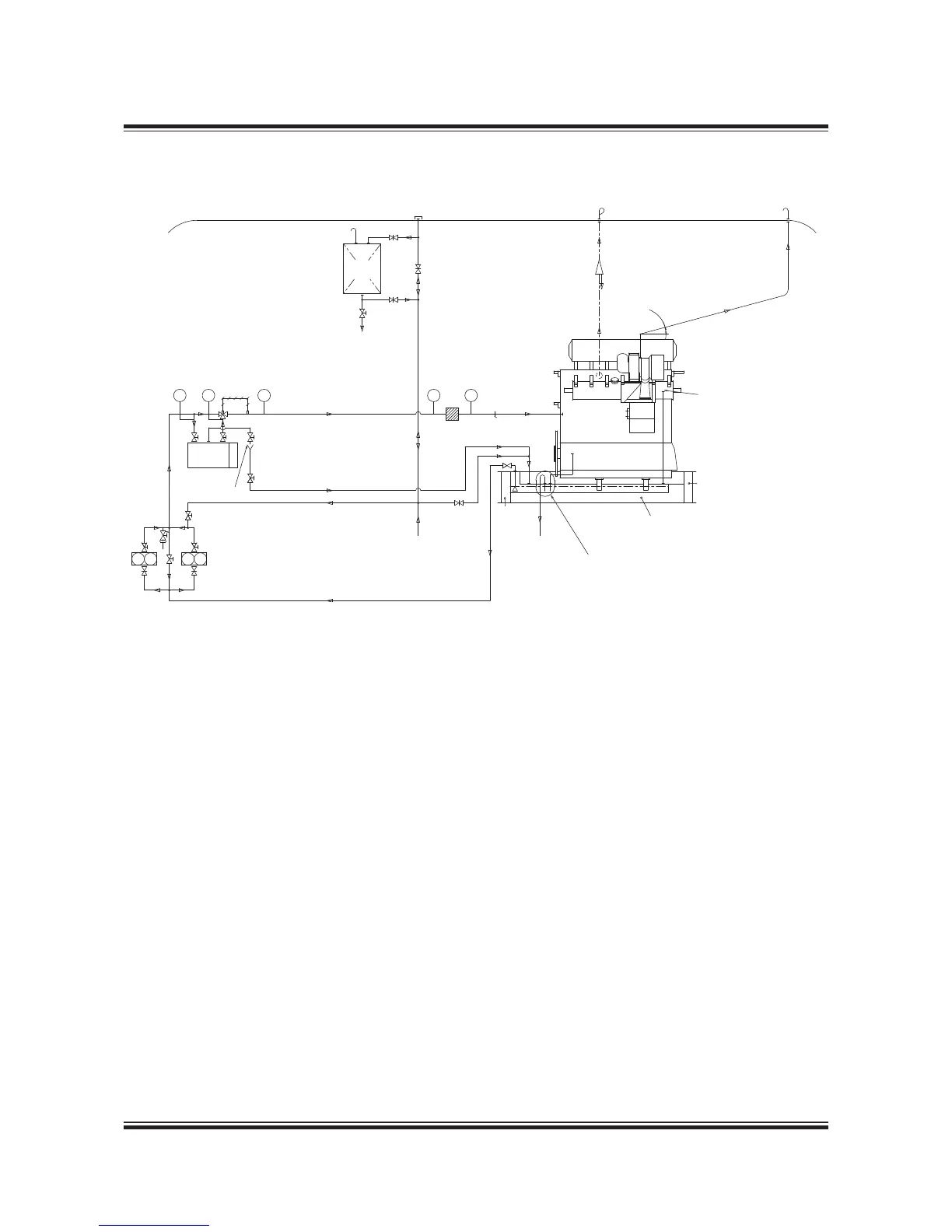

The lubricating oil is pumped from a bottom tank,

by means of the main lubricating oil pump (4 40 60),

to the lubricating oil cooler (4 40 605), a thermo-

static valve (4 40 60) and, through a fullow lter

(4 40 65), to the engine inlet RU, Fig. 8.0.0.

RU lubricates main bearings, thrust bearing, axial

vibration damper, piston cooling, crosshead bear-

ings, crankpin bearings. It also supplies oil to the

Hydraulic Power Supply unit and to moment com-

pensator and torsional vibration damper.

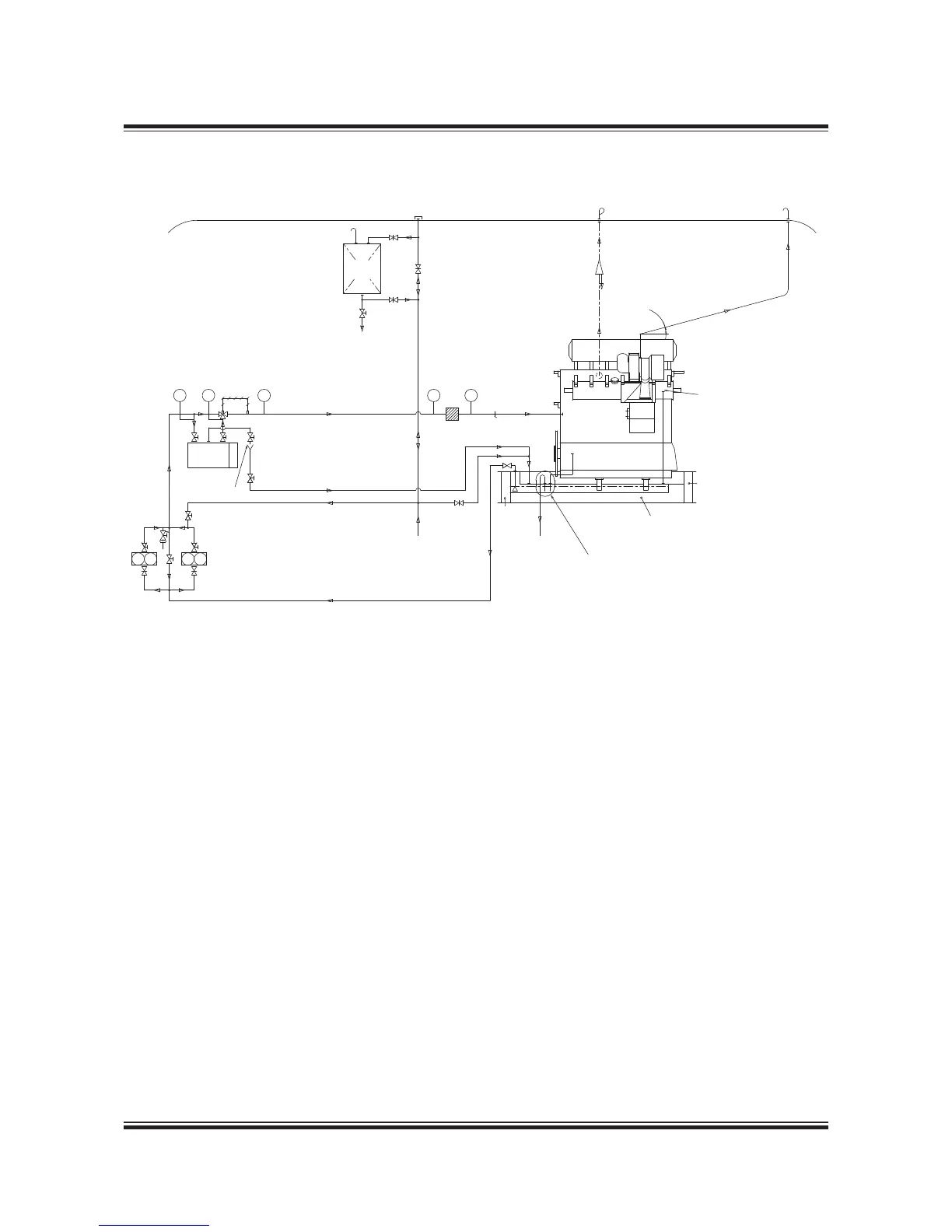

Lubrication of turbochargers

Turbochargers with slide bearings are normally

lubricated from the main engine system. AB is

outlet from the turbocharger, see Figs. 8.03.0 to

8.03.04, which are shown with sensors for UMS.

Figs. 8.03.0 to 8.03.04 show the lube oil pipe ar-

rangements for different turbocharger makes.

Fig. 8.01.01 Lubricating and cooling oil system

Loading...

Loading...