MAN B&W 6.04

Page 6 of 12

MAN Diesel

MAN B&W ME/MEC/MEGI engines 198 43 012.2

Jacket Cooling Water Temperature Control

When using a normal freshwater generator of the

singleeffect vacuum evaporator type, the fresh-

water production may, for guidance, be estimated

as 0.03 t/24h per 1 kW heat, i.e.:

M

fw

= 0.03 x Q

jw

t/24h 1%/0% [3]

where

M

fw

is the freshwater production in tons per 24

hours

and

Q

jw

is to be stated in kW

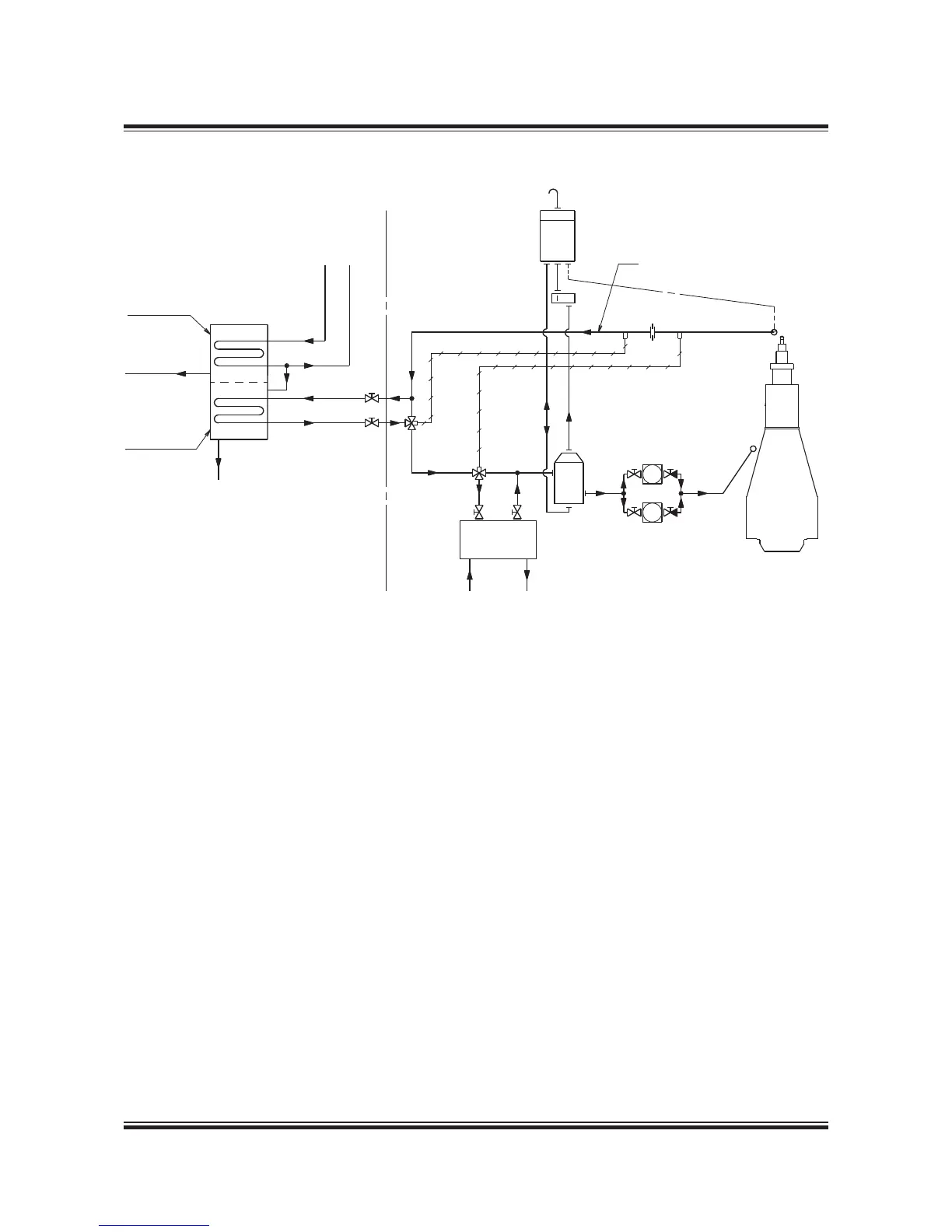

Valve A: ensures that T

jw

< 8° C

Valve B: ensures that T

jw

> 8 – ° C = 80° C

Valve B and the corresponding bypass may be omitted if, for example, the freshwater generator is equipped with an automatic

start/stop function for too low jacket cooling water temperature

If necessary, all the actually available jacket cooling water heat may be utilised provided that a special temperature control system

ensures that the jacket cooling water temperature at the outlet from the engine does not fall below a certain level

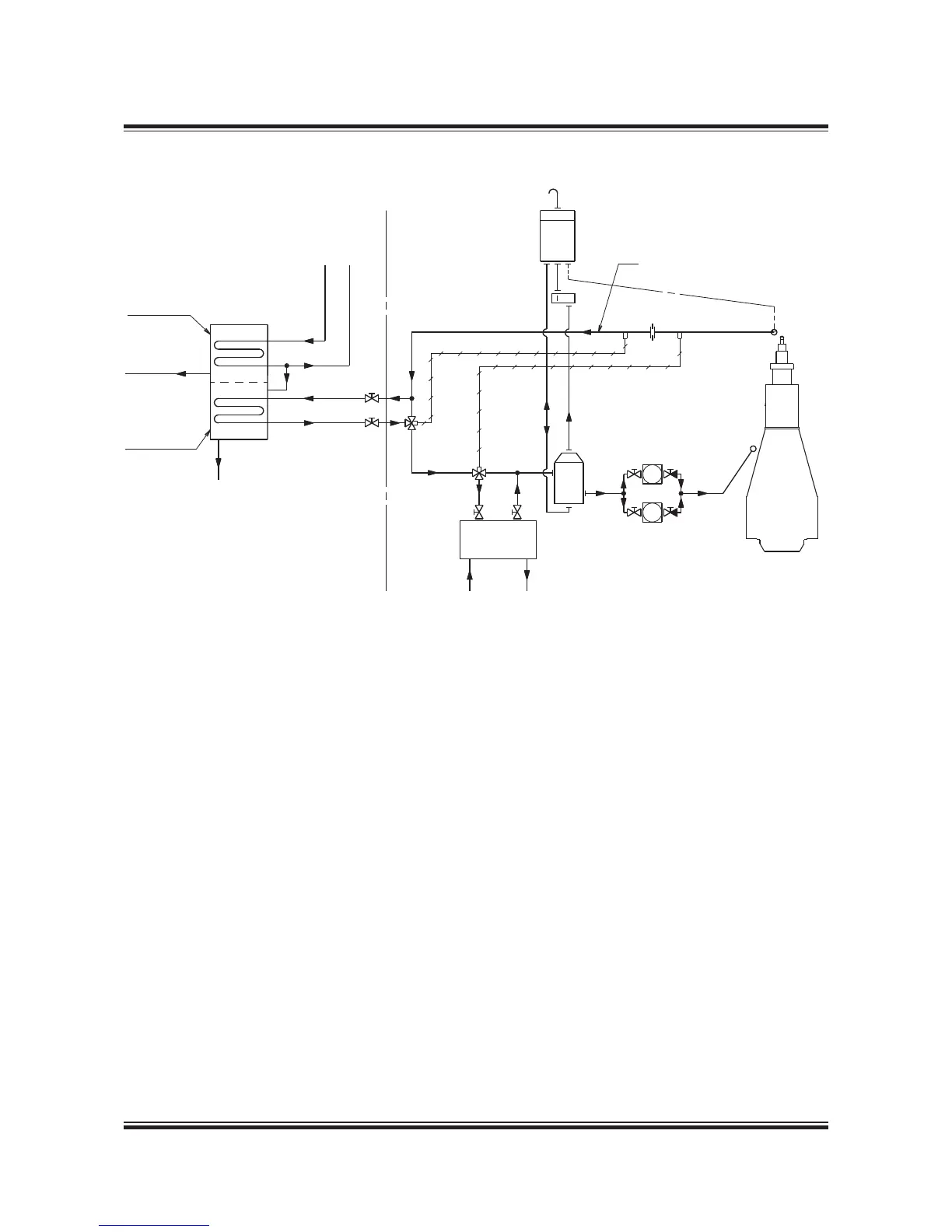

Fig. 6.04.05: Freshwater generators. Jacket cooling water heat recovery ow diagram

178 23 700.0

If necessary, all the actually available jacket cool-

ing water heat may be used provided that a special

temperature control system ensures that the jacket

cooling water temperature at the outlet from the

engine does not fall below a certain level. Such a

temperature control system may consist, e.g., of a

special bypass pipe installed in the jacket cooling

water system, see Fig. 6.04.0, or a special builtin

temperature control in the freshwater generator,

e.g., an automatic start/stop function, or similar.

If such a special temperature control is not applied,

we recommend limiting the heat utilised to maxi-

mum 0% of the heat actually available at specied

MCR, and only using the freshwater generator at

engine loads above 0%. Considering the cooler

margin of 10% and the minus tolerance of 1%,

this heat corresponds to 0 x(1.000.1)x0.9 = 38%

of the jacket water cooler capacity Q

jw,M

used for

dimensioning of the jacket water cooler.

Loading...

Loading...