MAN B&W 17.03

Page of 2

MAN Diesel

MAN B&W MC/MC-C/ME/ME-B/MEC/MEGI engines 198 42 221.4

178 57 45-6.0

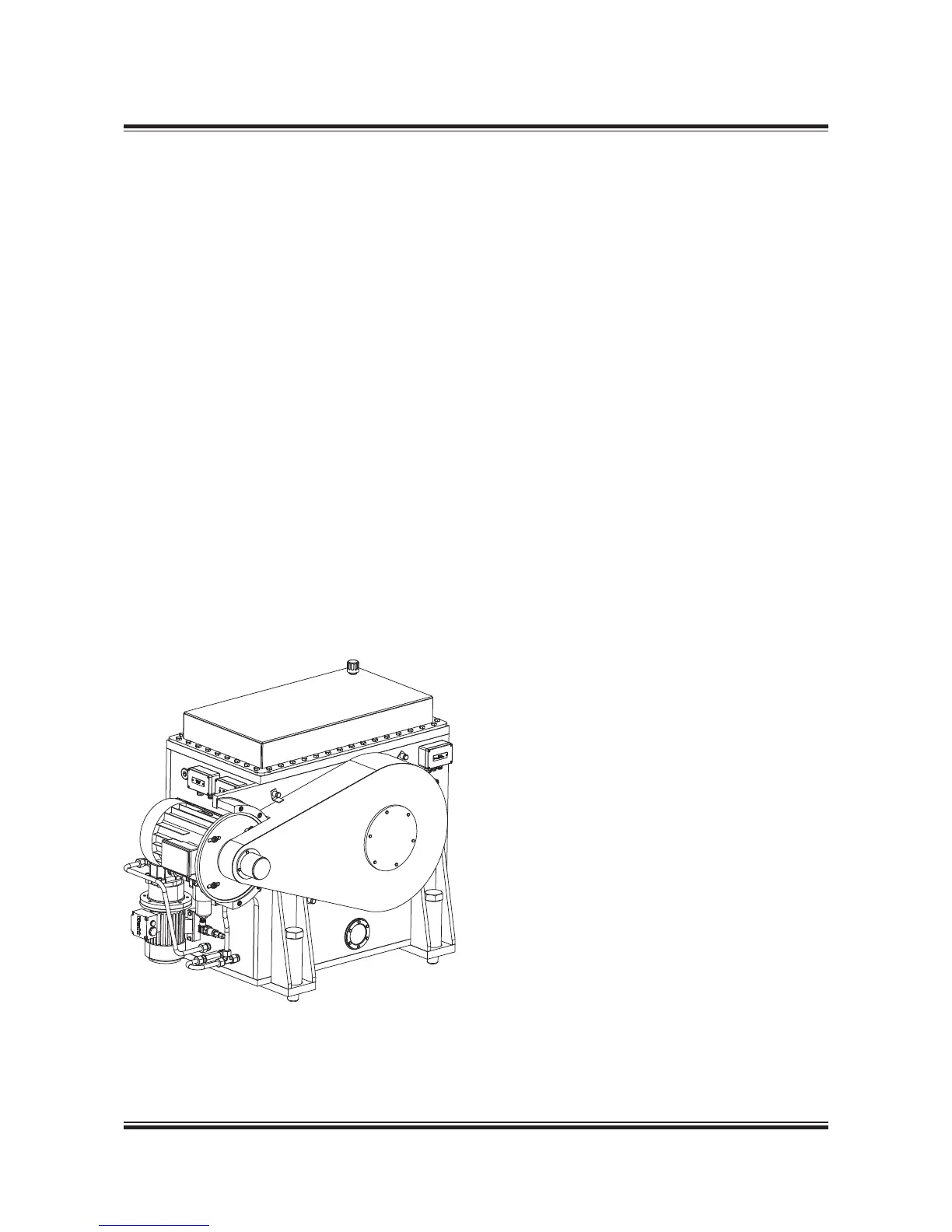

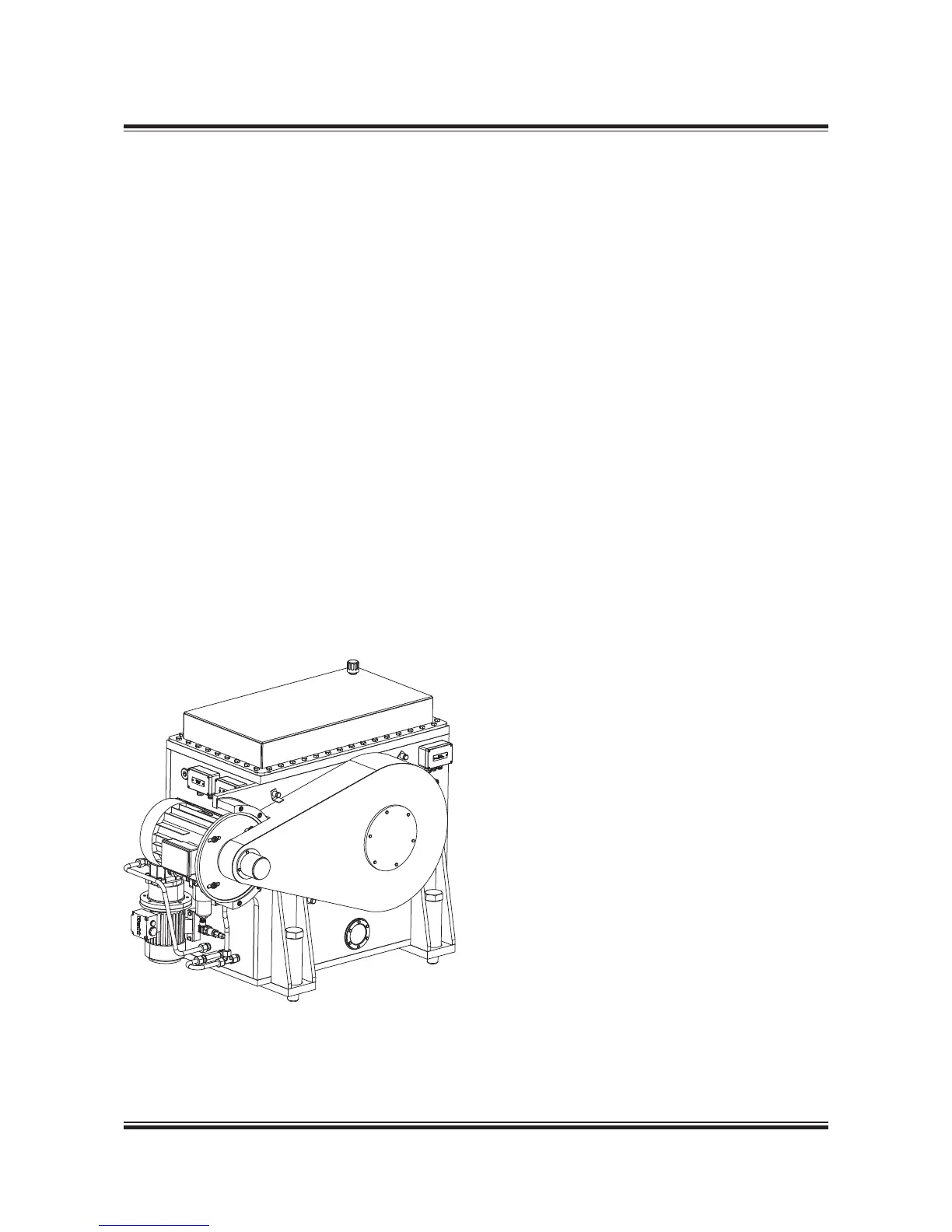

Fig. 17.03.01: MAN Diesel 1st or 2nd order electrically driven moment compensator, separately mounted,

option: 4 31 605.

Electric Driven Moment Compensator

If it is decided not to use chain driven moment

compensators and, furthermore, not to prepare

the main engine for compensators to be tted

later, another solution can be used, if annoying

vibrations should occur: An electrically driven

moment compensator synchronised to the cor-

rect phase relative to the external force or mo-

ment can neutralise the excitation.

This type of compensator needs an extra seating

tted, preferably, in the steering gear room where

vibratory deections are largest and the effect of

the compensator will therefore be greatest.

The electrically driven compensator will not give

rise to distorting stresses in the hull, but it is more

expensive than the engine-mounted compensa-

tors. It does, however, offer several advantages

over the engine mounted solutions:

• When placed in the steering gear room, the

compensator is not as sensitive to the position-

ing of the node as the compensators 2) and 3)

mentioned in Section 7.02.

• The decision whether or not to install compen-

sators can be taken at a much later stage of a

project, since no special version of the engine

structure has to be ordered for the installation.

• No preparation for a later installation nor an ex-

tra chain drive for the compensator on the fore

end of the engine is required. This saves the

cost of such preparation, often left unused.

• Compensators could be retrot, even on ships

in service, and also be applied to engines with a

higher number of cylinders than is normally con-

sidered relevant, if found necessary.

• The compensator only needs to be active at

speeds critical for the hull girder vibration. Thus,

it may be activated or deactivated at specied

speeds automatically or manually.

• Combinations with and without moment com-

pensators are not required in torsional and axial

vibration calculations, since the electrically

driven moment compensator is not part of the

mass-elastic system of the crankshaft.

Furthermore, by using the compensator as a vi-

bration exciter a ship’s vibration pattern can easily

be identied without having the engine running,

e.g. on newbuildings at an advanced stage of

construction. If it is veried that a ship does not

need the compensator, it can be removed and re-

used on another ship.

It is a condition for the application of the rotating

force moment compensator that no annoying lon-

gitudinal hull girder vibration modes are excited.

Based on our present knowledge, and conrmed

by actual vibration measurements onboard a ship,

we do not expect such problems.

Loading...

Loading...