MAN B&W 17.05

Page of

MAN Diesel

MAN B&W ME/ME-B/MEC/MEGI engines 198 45 170.5

As the deection shape for the Htype is equal

for each cylinder the N

th

order Htype guide force

moment for an Ncylinder engine with regular r-

ing order is:

N x M

H(one cylinder)

For modelling purposes the size of the forces in

the force couple is:

Force = M

H

/L [kN]

where L is the distance between crankshaft level

and the middle position of the crosshead guide

(i.e. the length of the connecting rod.)

As the interaction between engine and hull is at

the engine seating and the top bracing positions,

this force couple may alternatively be applied in

those positions with a vertical distance of (L

Z

).

Then the force can be calculated as:

Force

Z

= M

H

/L

Z

[kN]

Any other vertical distance may be applied, so as

to accomodate the actual hull (FEM) model.

The force couple may be distributed at any

number of points in the longitudinal direction. A

reasonable way of dividing the couple is by the

number of top bracing and then applying the forc-

es at those points.

Force

Z, one point

= Force

Z, total

/N

top bracing, total

[kN]

Xtype Guide Force Moment (M

X

)

The Xtype guide force moment is calculated

based on the same force couple as described

above. However as the deection shape is twist-

ing the engine each cylinder unit does not contrib-

ute with an equal amount. The centre units do not

contribute very much whereas the units at each

end contributes much.

A socalled ‘Bimoment’ can be calculated (Fig.

17.05.01):

‘Bimoment’ = Σ [forcecouple(cyl.X) x distX]

in kNm

2

The Xtype guide force moment is then dened

as:

M

X

= ‘BiMoment’/L kNm

For modelling purpose the size of the four (4) forc-

es can be calculated:

Force = M

X

/L

X

[kN]

where:

L

X

is the horizontal length between ‘force points’

Similar to the situation for the Htype guide force

moment, the forces may be applied in positions

suitable for the FEM model of the hull. Thus the

forces may be referred to another vertical level L

Z

above crankshaft centre line. These forces can be

calculated as follows:

Force

Z, one point

=

M

x

x L

_____

L x L

[kN]

In order to calculate the forces it is necessary

to know the lengths of the connecting rods = L,

which are:

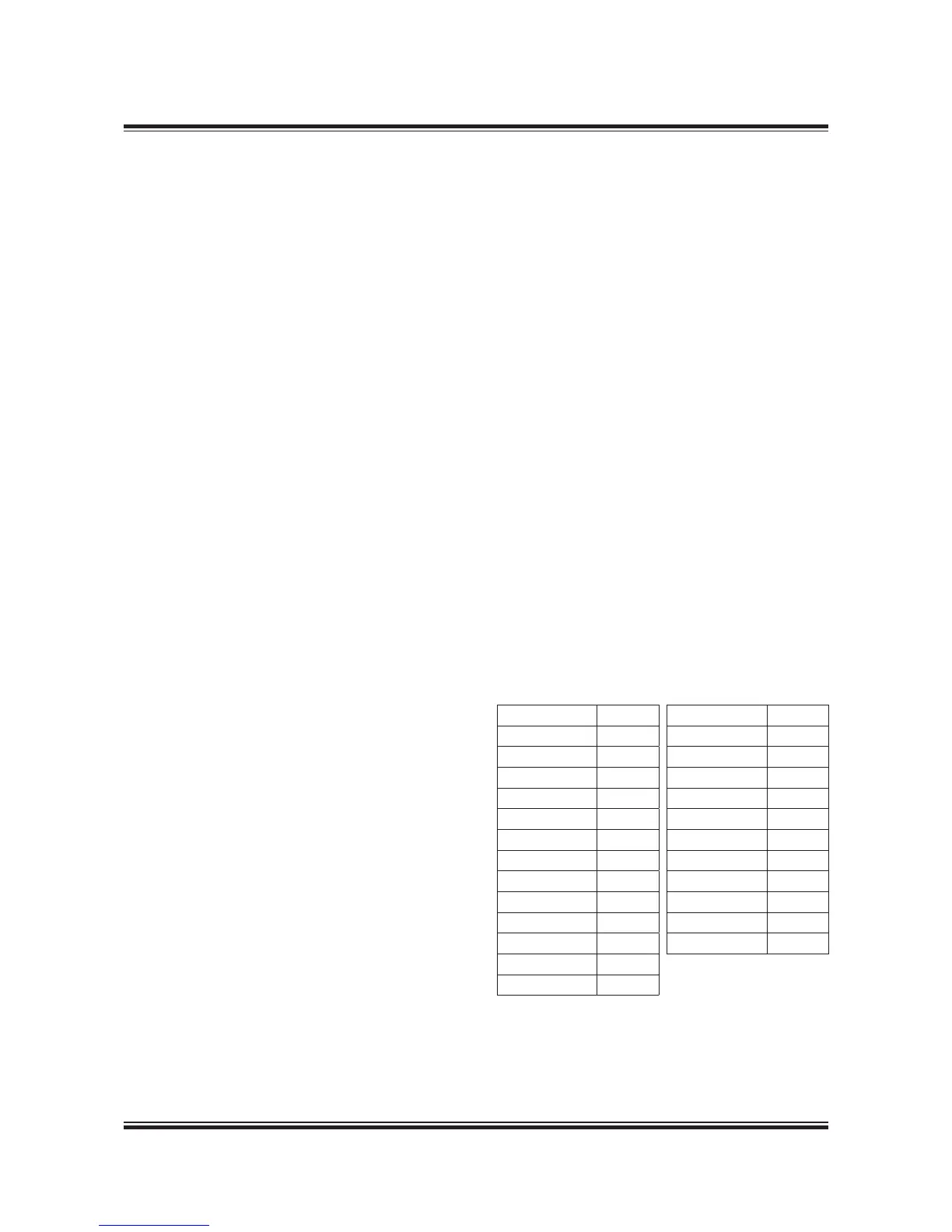

Engine Type L in mm

K108MEC6 ,400

K98ME6/7 ,220

K98MEC6/7 ,090

S90MEC7/8 ,270

K90ME9 ,20

K90ME-C9 ,120

K90MEC6 ,159

S80MEC9 ,450

S80MEC7/8 ,280

K80MEC9 2,975

K80MEC6 2,920

S70ME-C7/8 2,870

S70MEGI7/8 2,870

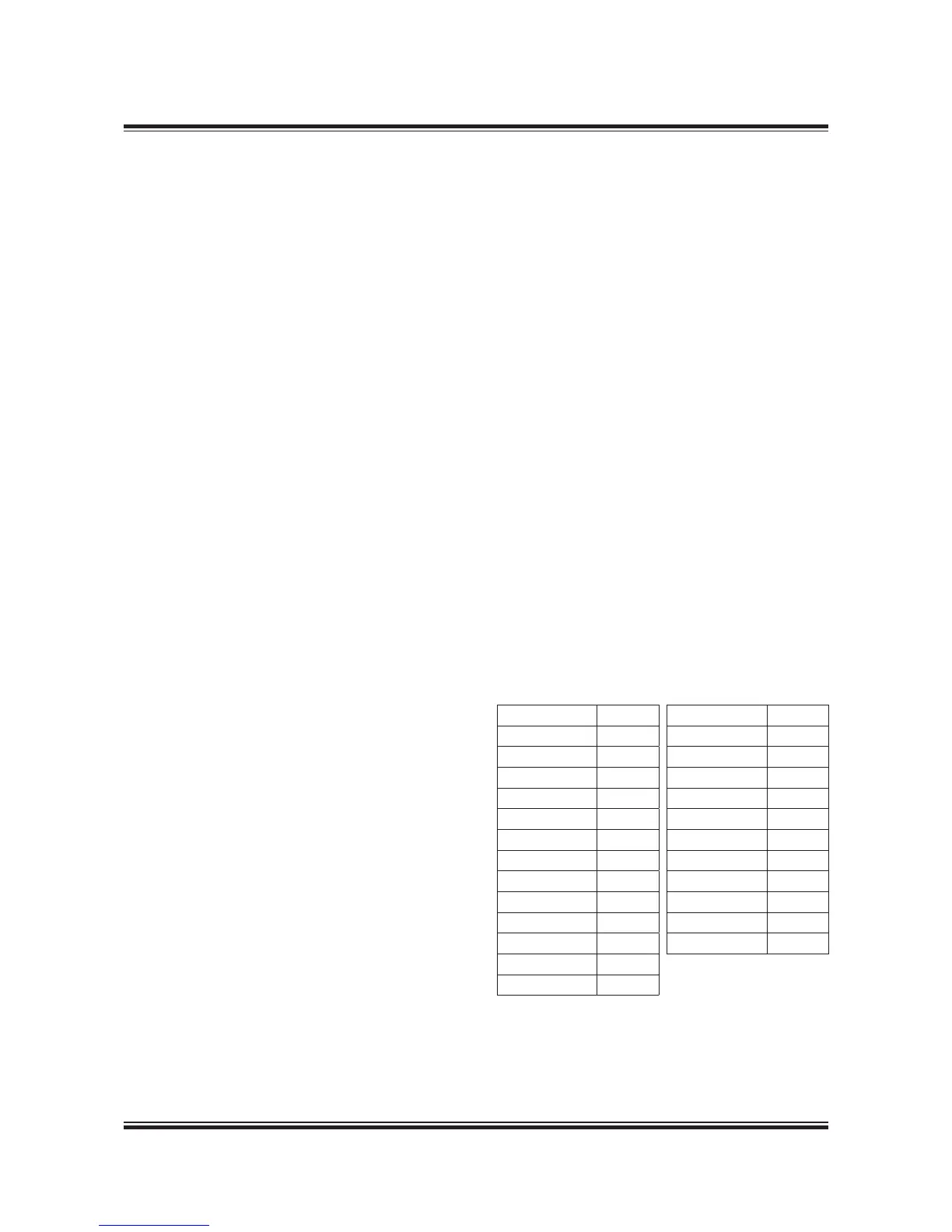

Engine Type L in mm

L70MEC7/8 2,660

S65MEC8 2,70

S65MEGI8 2,70

S60MEC7/8 2,460

S60MEGI7/8 2,460

L60MEC7/8 2,280

S50MEC7/8 2,050

S50ME-B9 2,114

S50ME-B8 2,050

S40ME-B9 1,770

S5ME-B9

1,550

Loading...

Loading...