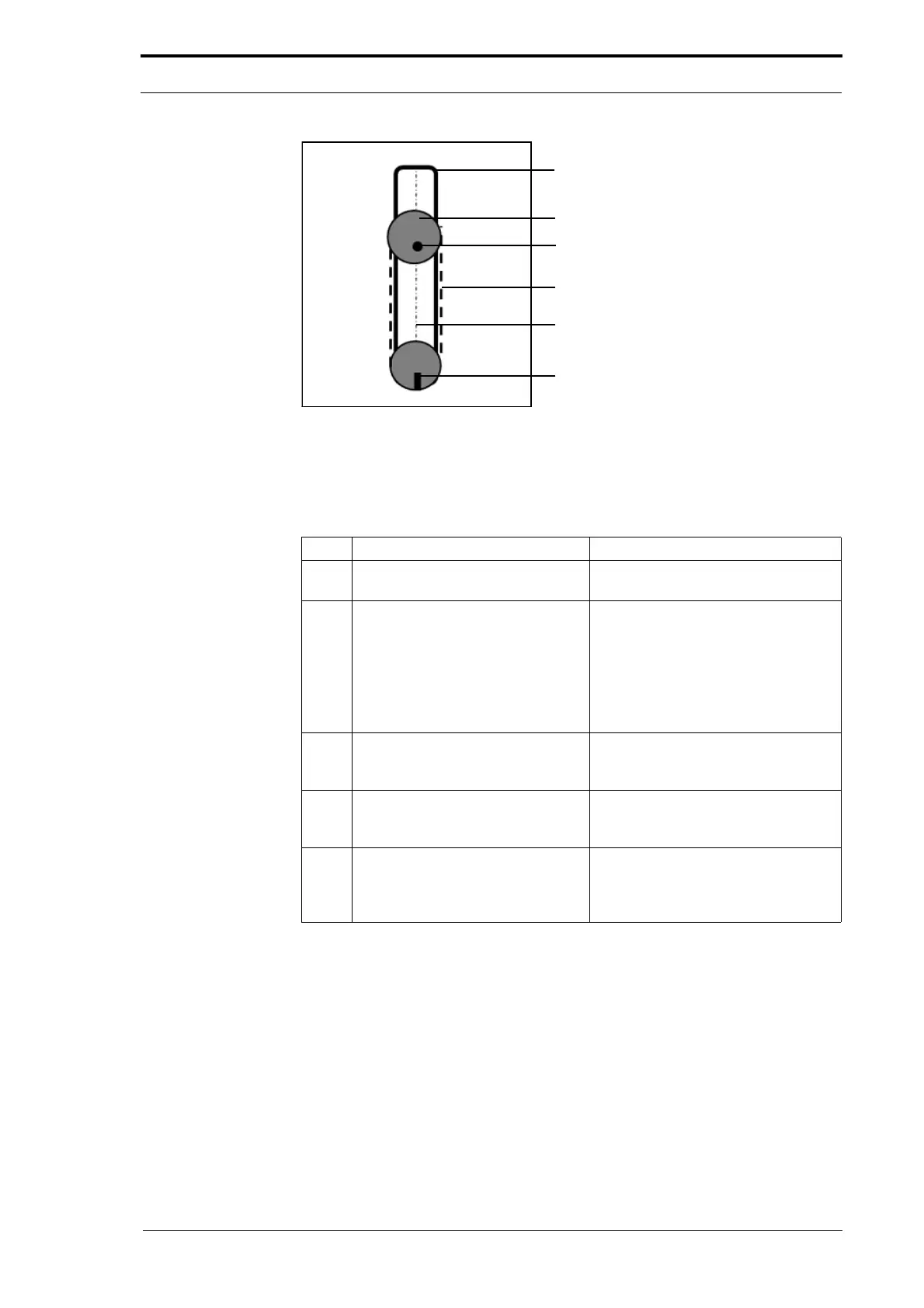

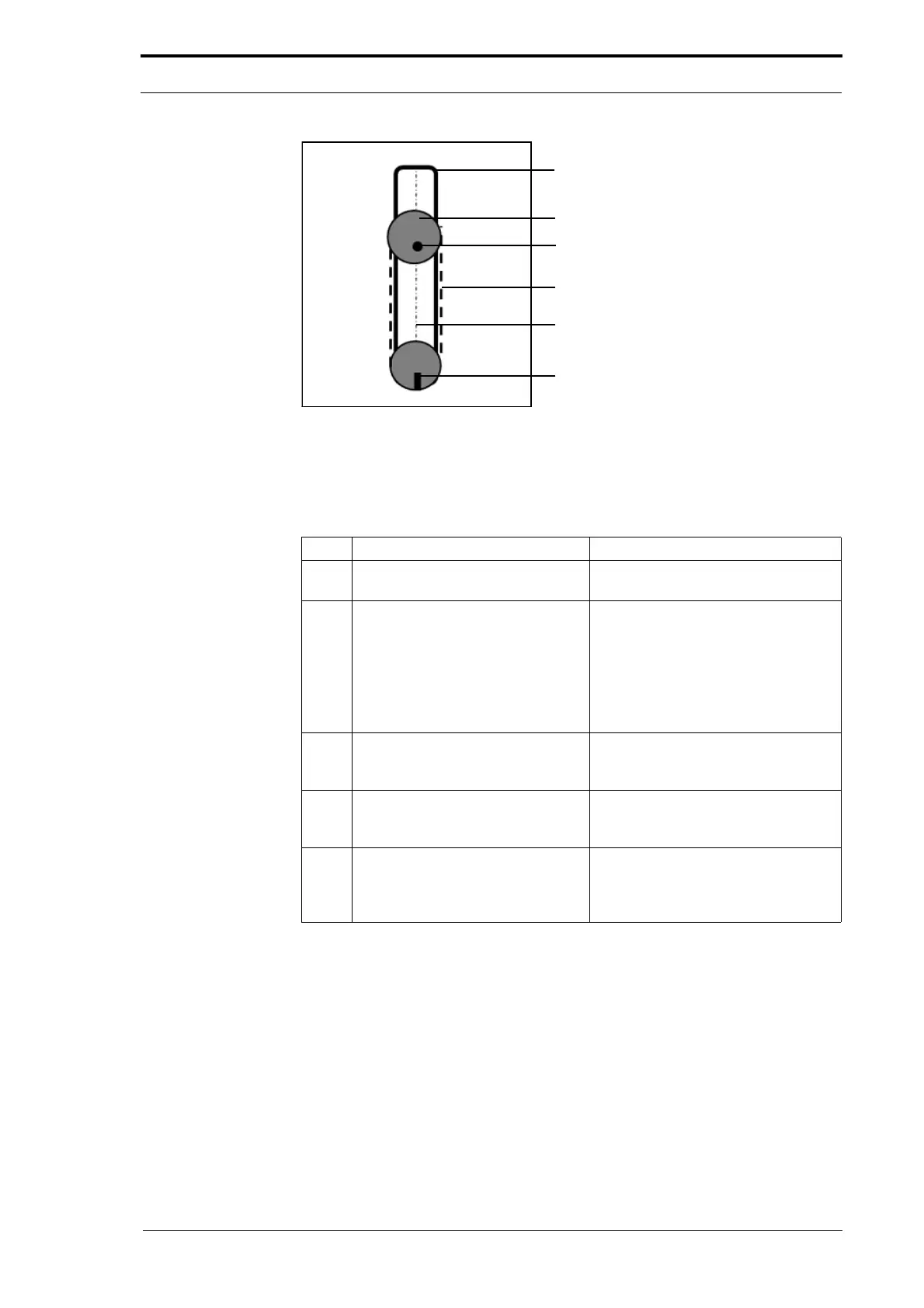

Feed Head

Adjuster Pulley

Location Pin

Timing Belt

Centre Line

Separation Adjuster

(Central Position)

4. Service Procedures - Machine Adjustments and Calibration

62 Morgana DocuMaster MFC - Service Manual

Figure 4.28 Suction Feed Head Separation Adjuster Calibration

When to do:

• If the suction feed bin feed head has been dismantled to replace the feed band.

• If the suction feed head separation adjuster does not seem to work correctly.

Step Action Information

1 Remove the feed band from the

suction feed head.

(See Section 4.8.2.2).

2 Set the separation adjuster so that

the

location pin in the adjuster

pulley faces the separation

adjuster and is in line with the

centre line of the feed head.

(See Figure 4.28).

• If the separation adjuster in the

central position as shown, the

feed head separation adjuster is

calibrated

• If the separation adjuster is not in

the central position go to step 3

3 Tilt the LH end of the support shaft

away from the feeder head to

release the timing belt tension.

4 Rotate the separation adjuster until

the

green indicator bar is in the

central position.

Hold the adjuster pulley to prevent it

from moving.

5 Reset the support shaft and check

that the sep

arator adjuster and the

location pin on the adjuster pulley

are in line.

When the separation adjuster is

calibrated correctly, replace the feed

band and re-check the calibration

before you fit the suction feed head.

4.5.5 Address the Feed Bins

Each feed bin is numbered so that the operator can identify where he needs to load

paper. The MFC control system has to be told how many bins are installed and, where

they are, by a manual address procedure. When the feed bins have been addressed in

sequence from bin 1 to bin 4, the MFC can synchronise and control the sheet feeding.

Loading...

Loading...