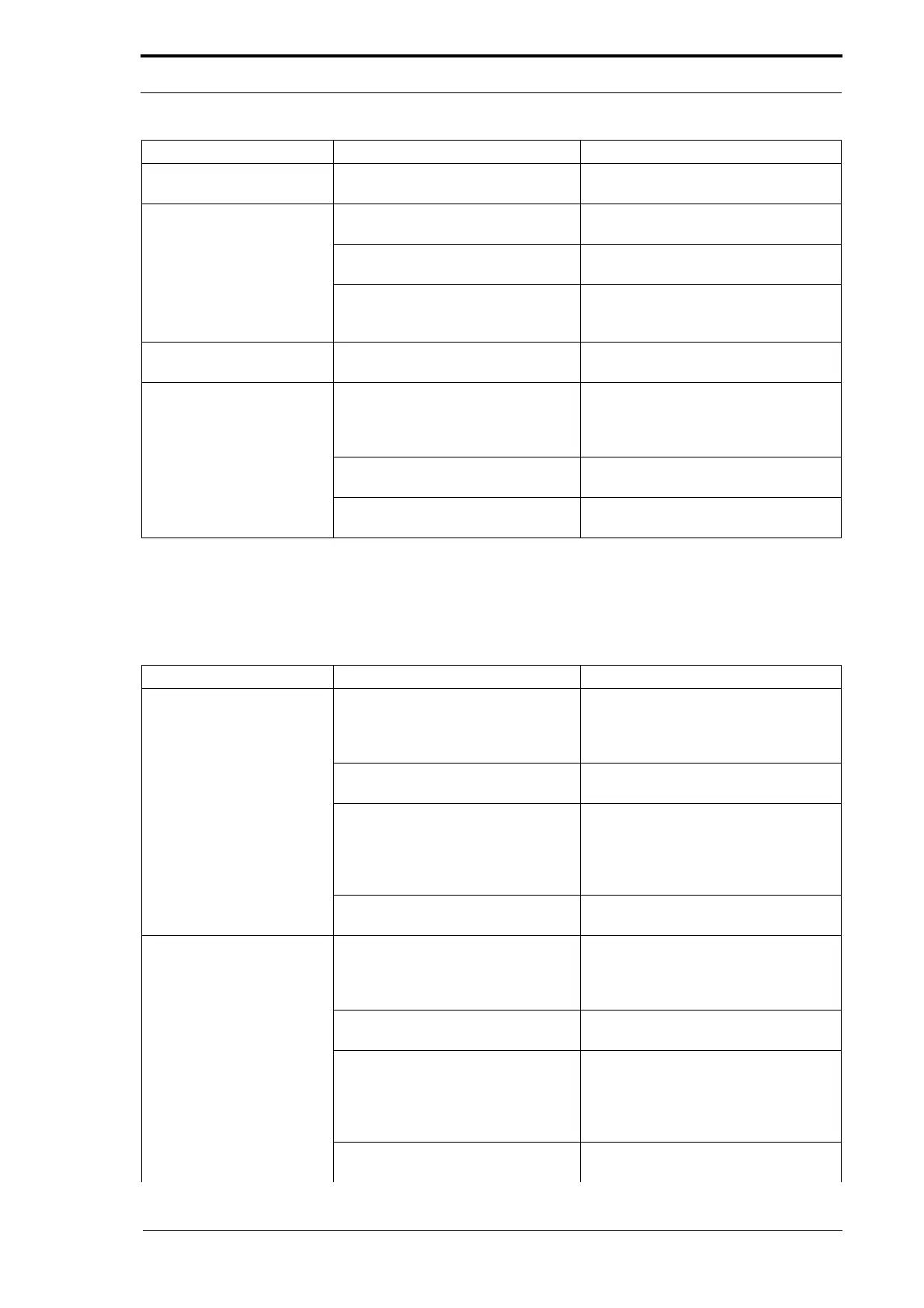

2. Error Conditions - MFC Error Procedure

26 Morgana DocuMaster MFC - Service Manual

2.1.7 Creaser Module Problems

Also (See Section 2.2) Paper Jams and (See Section 3.1) Crease Quality.

The feed clutch is defective (causes

clutch drag).

Replace the feed clutch (see Section

4.9.2).

There is marking on the

lead-edge of the sheet.

The stock is unsuitable for the

friction feed bin.

Put the stock in a suction feed bin.

There is too much tray pressure. Decrease the tray pressure (See MFC

User Operating Instructions Manual).

There is too much separator

pressure.

Decrease the separator pressure (See

MFC User Operating Instructions

Manual).

The paper tray will not lift/

go down.

A lower paper guide is not clipped

down which stops the paper tray.

Check the lower paper guides.

The paper tray shows

empty when it is loaded.

The bottom sheet has a solid area of

black ink/toner which does not

deflect light from the tray loaded

sensor.

Turn the job around when possible.

Place a sheet of unprinted paper

below the paper stack.

The tray loaded sensor is defective. Replace the tray loaded sensor (see

Section 4.9.5).

The feed bin control PCB is

defective.

Replace the feed bin control PCB (see

Section 4.9.3).

Problem Cause Solution

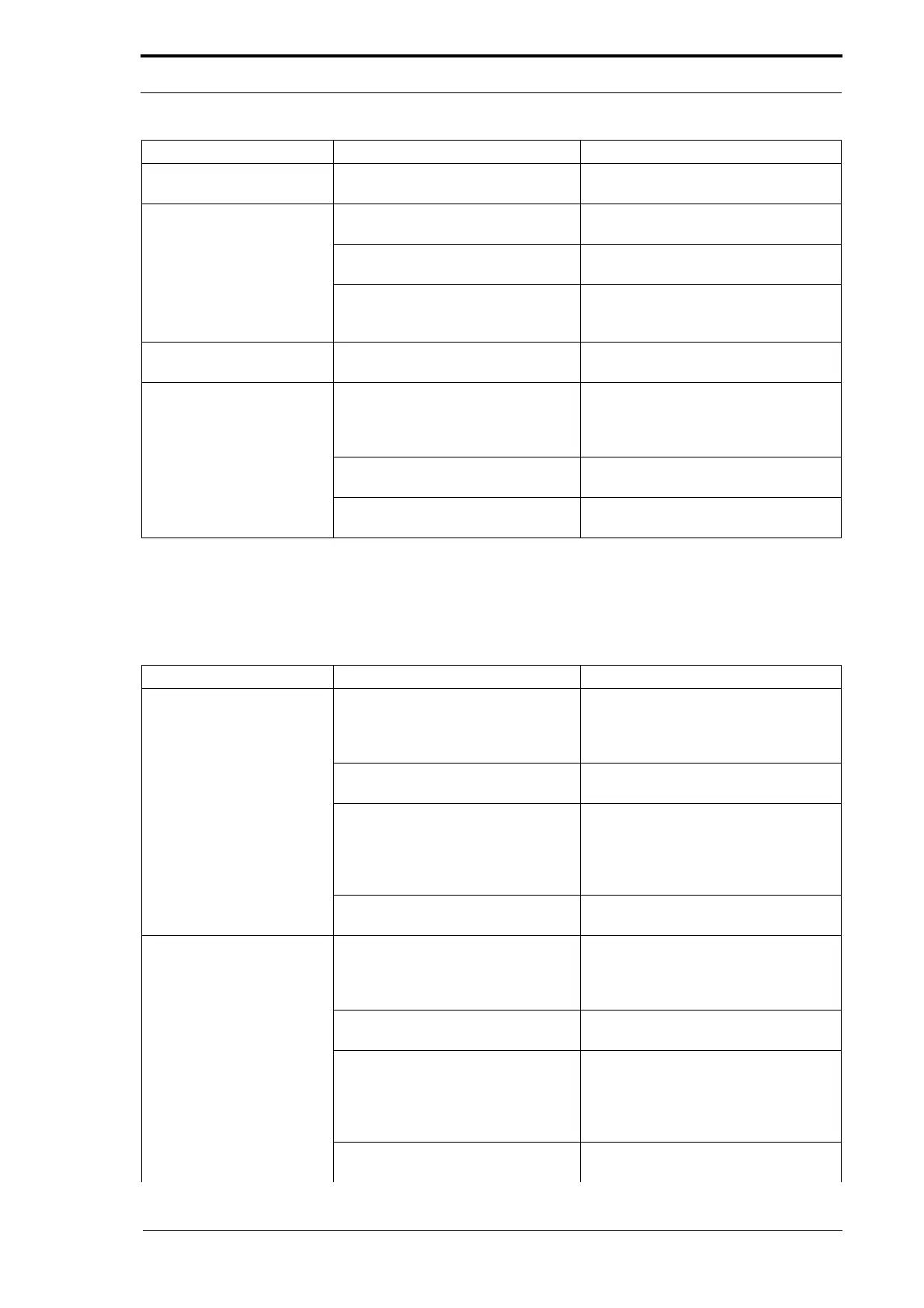

Problem Cause Solution

The main drive motor

does not start.

There is no power to the high power

stepper PCB.

Check the power supply to the high

power stepper PCB.

Replace a PSU (see Section 4.12.6) or

(see Section 4.12.7).

The high power stepper PCB is

defective.

Replace the high power stepper PCB

(see Section 4.12.4).

There is to signal to the high power

stepper PCB.

Check the signal cable connection

between the high power stepper PCB

and the controller PCB.

Replace the controller PCB (see

Section 4.12.2).

The main drive motor is defective. Replace the main drive motor (see

Section 4.7.2).

The creaser drive motor

does not start.

There is no power on the dual

stepper PCB.

Check the power supply to the dual

stepper PCB.

Replace a PSU (see Section 4.12.6) or

(see Section 4.12.7).

The dual stepper PCB is defective. Replace the dual stepper PCB (see

Section 4.12.3).

There is no signal to the dual

stepper PCB.

Check the signal cable connection

between the dual stepper PCB and the

controller PCB.

Replace the controller PCB (see

Section 4.12.2).

The creaser drive motor is defective. Replace the creaser drive motor (see

Section 4.10.10).

Loading...

Loading...