Morgana DocuMaster MFC - Service Manual 27

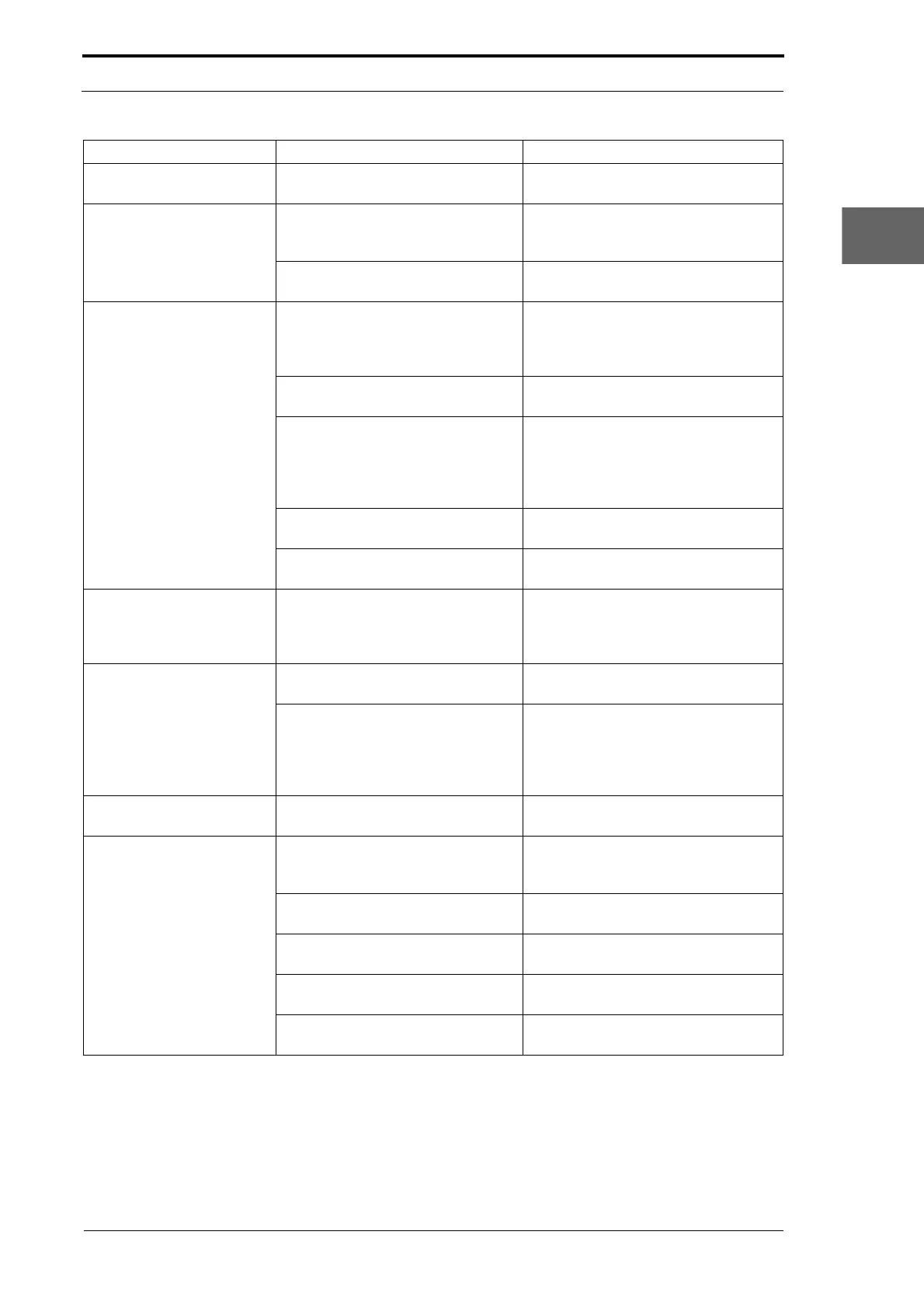

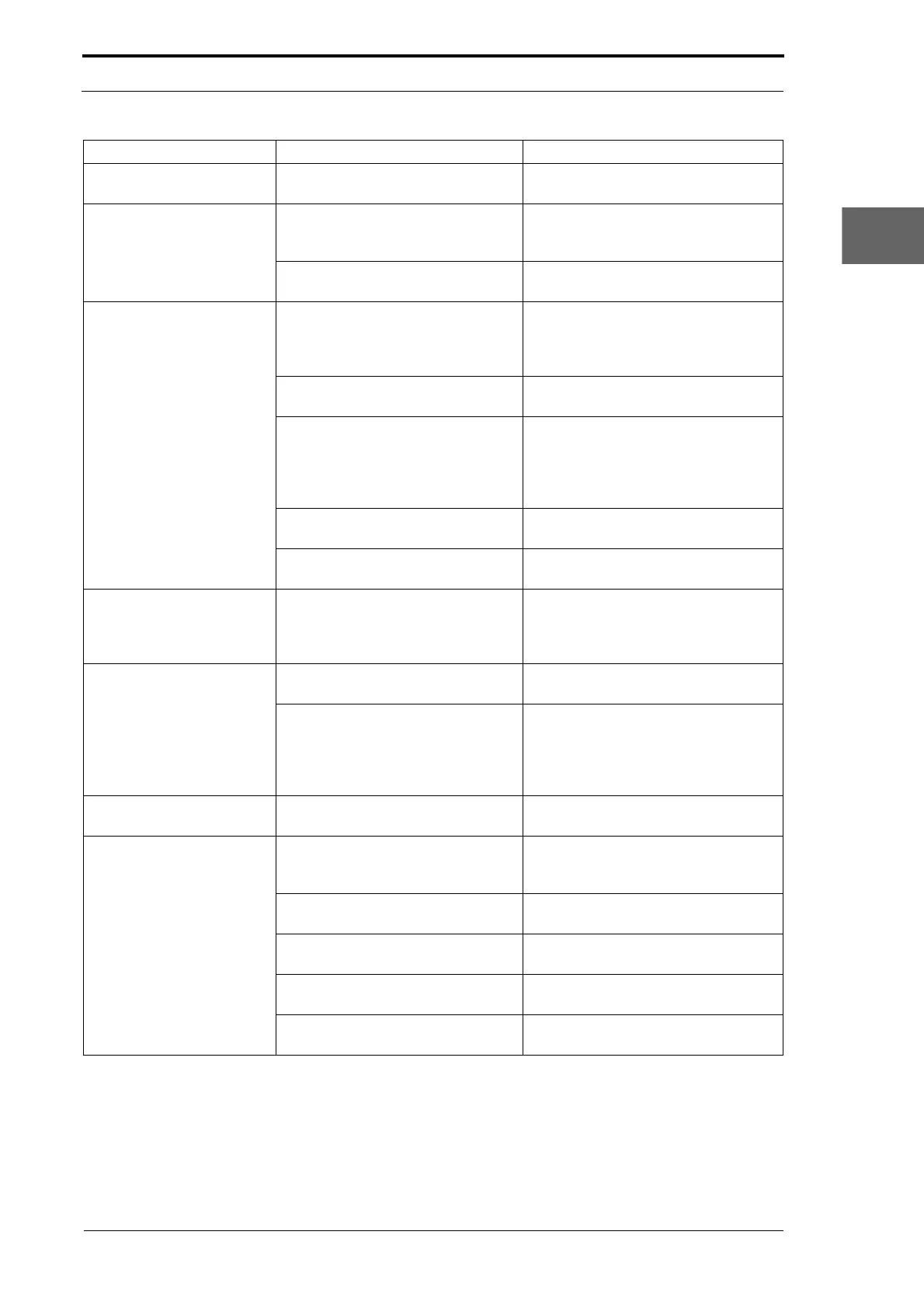

2. Error Conditions - MFC Error Procedure

The creaser drive makes

an unusual noise.

The creaser drive motor gear-play is

not set correctly.

Adjust the creaser drive motor gear

play

(see Section 4.5.11).

The creaser input/output

rollers make an unusual

noise.

There is a sheet of paper wrapped

around a roller.

Remove the paper from the creaser

module (see Section 4.3.1).

The roller spring pressure is weak. Check the roller tension springs (see

Section 4.10.2.1).

The crease motor does

not start.

There is no power on the dual power

stepper PCB.

Check the power supply to the high

power stepper PCB.

Replace a PSU (see Section 4.12.6) or

(see Section 4.12.7).

The dual stepper PCB is defective. Replace the dual stepper PCB (see

Section 4.12.3).

There is to signal to the dual stepper

PCB.

Check the signal cable connection

between the dual stepper PCB and the

controller PCB.

Replace the controller PCB (see

Section 4.12.2).

The creaser drive motor is defective. Replace the creaser drive motor (see

Section 4.10.10).

A lead-edge sensor is dirty. Clean the edge sensor set (see

Section 4.13.4).

The crease blade-set

cycles constantly.

There is no input from the creaser

position sensor to the controller

PCB.

Check the creaser position sensor

cable connections.

Replace the creaser position sensor

assembly (see Section 4.10.7).

The DynaTilt mechanism

goes out of position.

The DynaTilt home switch is not set

correctly.

Check the DynaTilt home sequence

(see Section 4.5.16).

The is no signal to the low power

stepper PCB.

Check the signal cable connections

between the low power stepper PCB

and the controller PCB.

Replace the controller PCB (see

Section 4.12.2).

There is no power to the

controller PCB.

The 5V/24V PSU is defective. Replace the 5V/24V PSU (see Section

4.12.8).

The MFC shows a

‘Creaser Error 8’

message.

The sheet that fed was skewed too

far.

Check why the sheet was skewed.

One of the pair of lead-edge sensors

in use is blocked.

Remove the blockage (see Section

4.3.1).

One of the pair of lead-edge sensors

in use is dirty.

Clean the edge-sensor set (see

Section 4.13.4).

One of the pair of lead-edge sensors

in use is defective.

Replace the edge-sensor set (see

Section 4.10.6).

The controller PCB is defective. Replace the controller PCB (see

Section 4.12.2).

Problem Cause Solution

Loading...

Loading...