Morgana DocuMaster MFC - Service Manual 29

2. Error Conditions - Paper Jams

2.2 Paper Jams

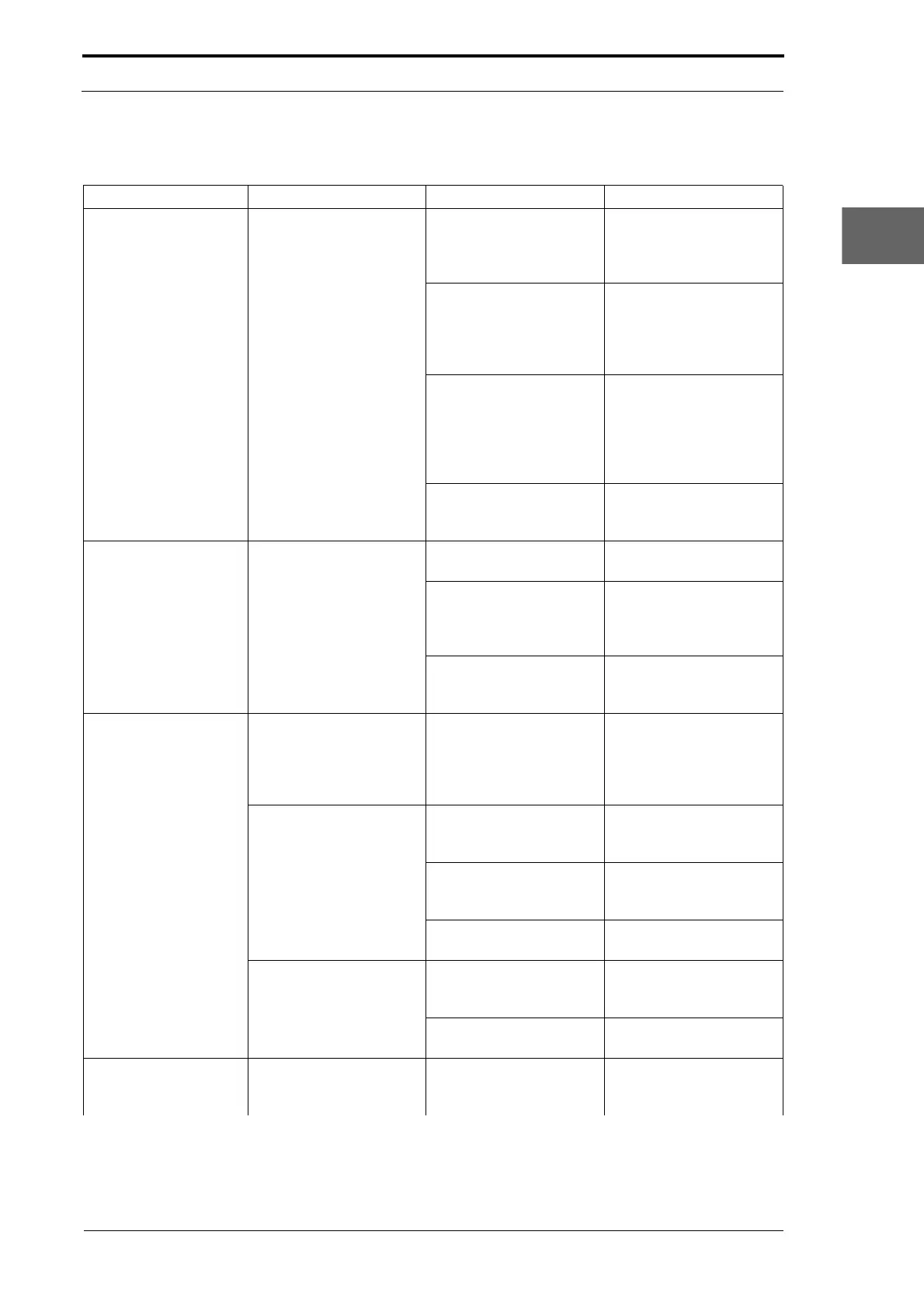

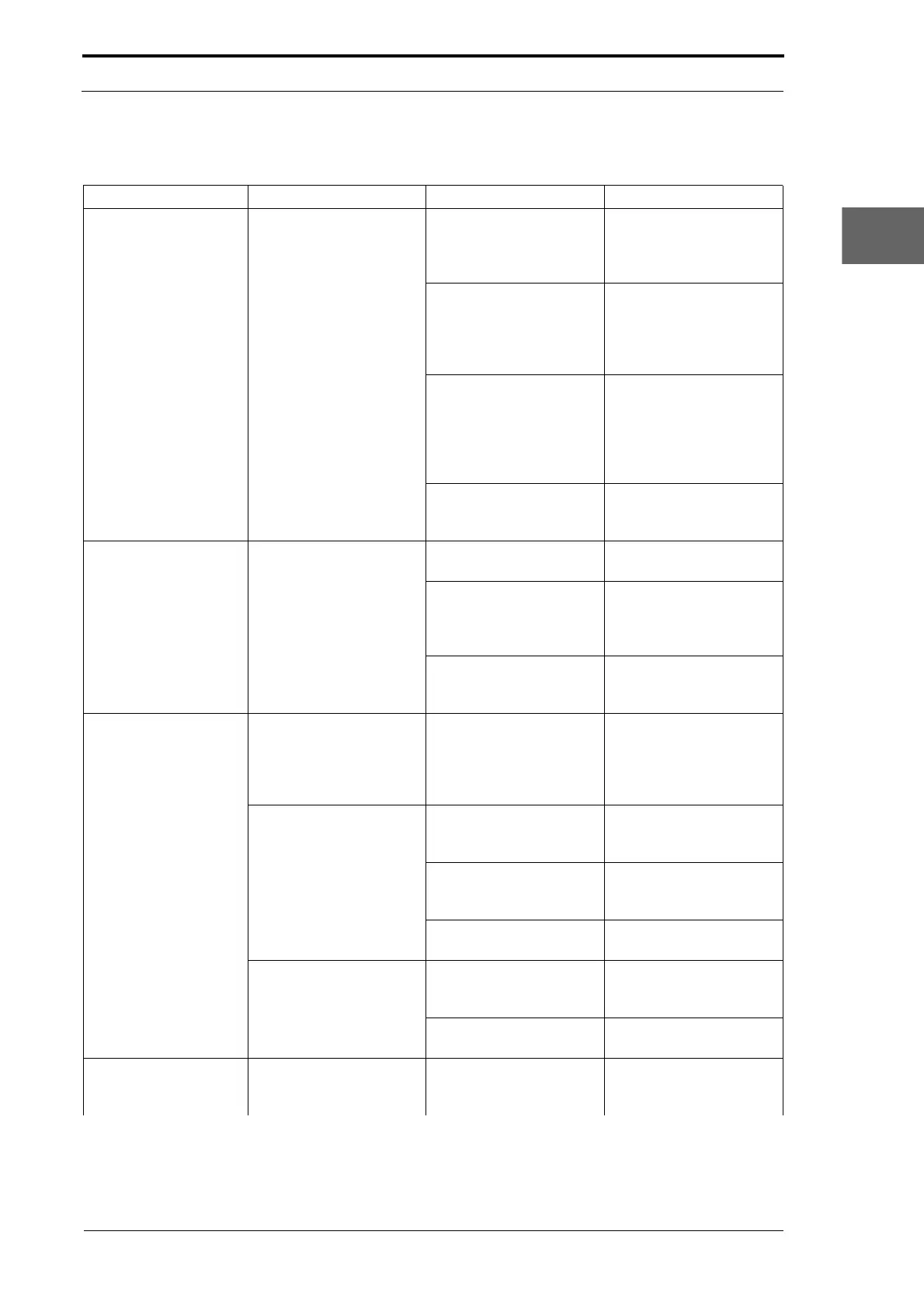

Jam Location Problem Cause Solution

FEED BIN The sheets do not feed

into the conveyor.

There is too much sheet

separation on the feeder.

Decrease the sheet

separation (see MFC

User Operating

Instructions Manual).

The paper is curled. Roll the paper to remove

the curl.

Advise the customer to

use better paper/review

the printing process.

There is an obstruction in

the paper path.

Check in the feed bin

guides for pieces of

paper.

Check that all of the feed

bin guides are clipped in

position.

The feed clutch is

defective.

Replace the feed clutch

(see Section 4.8.3) or

(see Section 4.9.2)

CONVEYOR The sheets stop in the

conveyor.

There is an obstruction in

the paper path.

Remove obstruction from

conveyor.

The outer conveyor

wheels are defective.

Replace the outer

conveyor wheels (see

Section 4.8.11) or (see

Section 4.9.6).

The inner conveyor

wheel is defective.

Replace the inner

conveyor wheel (see

Section 4.8.12).

CREASER MODULE A sheet has jammed in

the input rollers.

The paper is curled. Roll the paper to remove

the curl.

Advise the customer to

use better paper/review

the printing process.

The paper has hit the

blade-set.

The blade-set is not

installed correctly.

(See MFC User

Operating Instructions

Manual).

The anti-static brushes

are defective.

Replace the anti-static

brushes (see Section

4.10.11).

The anti-static brushes

are installed incorrectly.

(See Section 4.10.11).

The sheet has jammed

after it was creased.

There is too much crease

pressure.

Adjust the crease

pressure (see Section

4.5.17).

There is an obstruction in

the gathering area.

Remove the obstruction

from the gathering area.

GATHERING AREA The sheets do not stack

tidily.

The A4 pinch drive is not

set correctly.

Set A4 pinch drive (see

MFC User Operating

Instructions Manual).

Loading...

Loading...