Morgana DocuMaster MFC - Service Manual 25

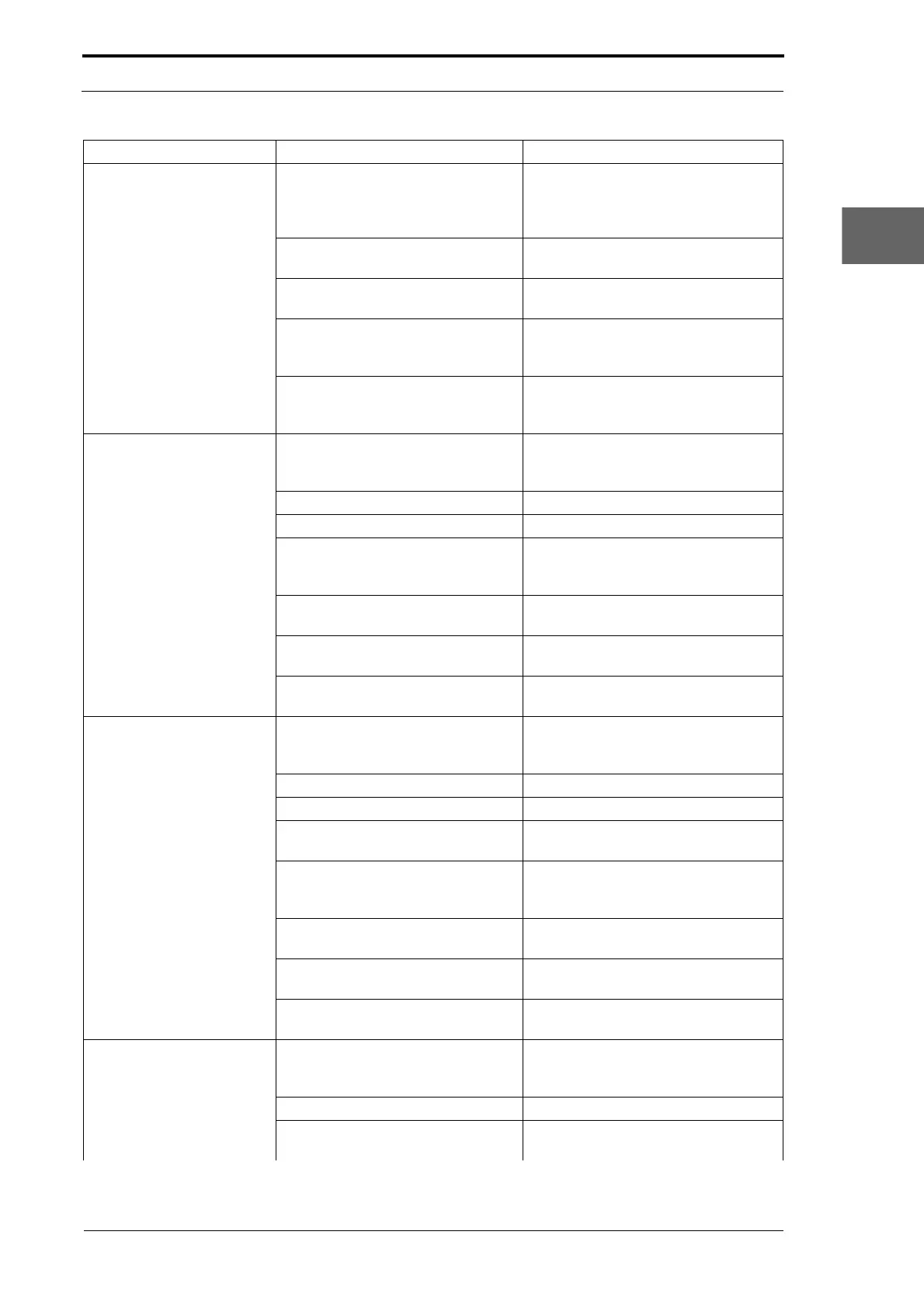

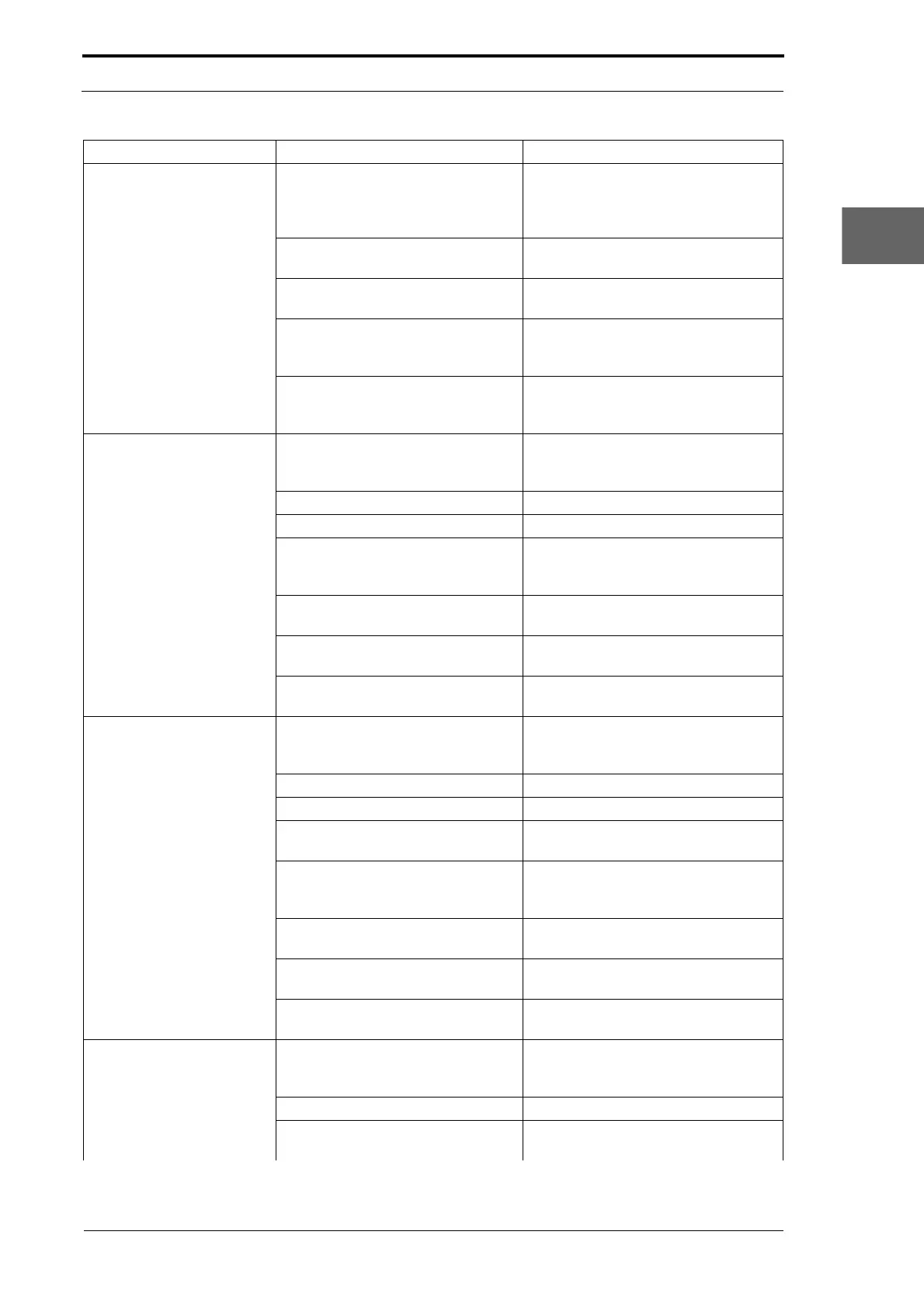

2. Error Conditions - MFC Error Procedure

The feed bin emitter/sensor if

defective.

Do a test on the feed bin emitter/

sensor assembly

(see Section 4.4.3).

Replace the feed bin emitter/sensor

assembly (see Section 4.8.8).

The feed bin control PCB is

defective.

Replace the feed bin control PCB (see

Section 4.8.7).

There was a bad Test Set. Do a Test Set (see MFC User

Operating Instructions Manual).

There is no unprinted margin on the

lead-edge of the sheets and the

printed image causes ‘false errors’.

Advise the customer to reprint the job.

The sensor position is not set to

read in the unprinted margin on the

lead-edge of the sheet

(See MFC User Operating Instructions

Manual).

Too many double feeds

occur.

The separator pressure is not set

correctly.

Adjust the separator pressure (see

MFC User Operating Instructions

Manual).

The separator pad is dirty. Clean the separator pad.

The separator pad is worn. Replace the separator.

The blue feed wheel feed shaft is

installed (not correct for uncoated

stock).

Install the white feed wheel feed shaft

(see Section 4.9.1.1).

The tray pressure is not set

correctly.

Adjust the tray pressure (see MFC

User Operating Instructions Manual).

The feed clutch is defective (causes

clutch drag).

Replace the feed clutch (see Section

4.9.2).

There was bad Test Set. Do a Test Set (see MFC User

Operating Instructions Manual).

Too many miss feeds

occur.

The separator pressure is not set

correctly.

Adjust the separator pressure (see

MFC User Operating Instructions

Manual).

The separator pad is worn. Replace the separator.

The feed wheels are dirty. Clean the feed wheels.

The feed wheels are worn. Replace the feed wheels (see Section

4.9.1).

The white feed wheel feed shaft is

installed (not correct for glossy

stocks).

Install the blue feed wheel feed shaft

(see Section 4.9.1.1).

The tray pressure is not set

correctly.

Adjust the tray pressure (see MFC

User Operating Instructions Manual).

The feed clutch is defective. Replace the feed clutch (see Section

4.9.2).

There was bad Test Set. Do a Test Set (see MFC User

Operating Instructions Manual).

The lead-edge of the

sheet is damaged.

The separator pressure is not set

correctly.

Adjust the separator pressure (see

MFC User Operating Instructions

Manual).

The separator pad is worn. Replace the separator.

The feed wheels are not in the

correct position.

Adjust the feed wheel position (see

Section 4.9.1).

Problem Cause Solution

Loading...

Loading...