4. Service Procedures - Machine Adjustments and Calibration

70 Morgana DocuMaster MFC - Service Manual

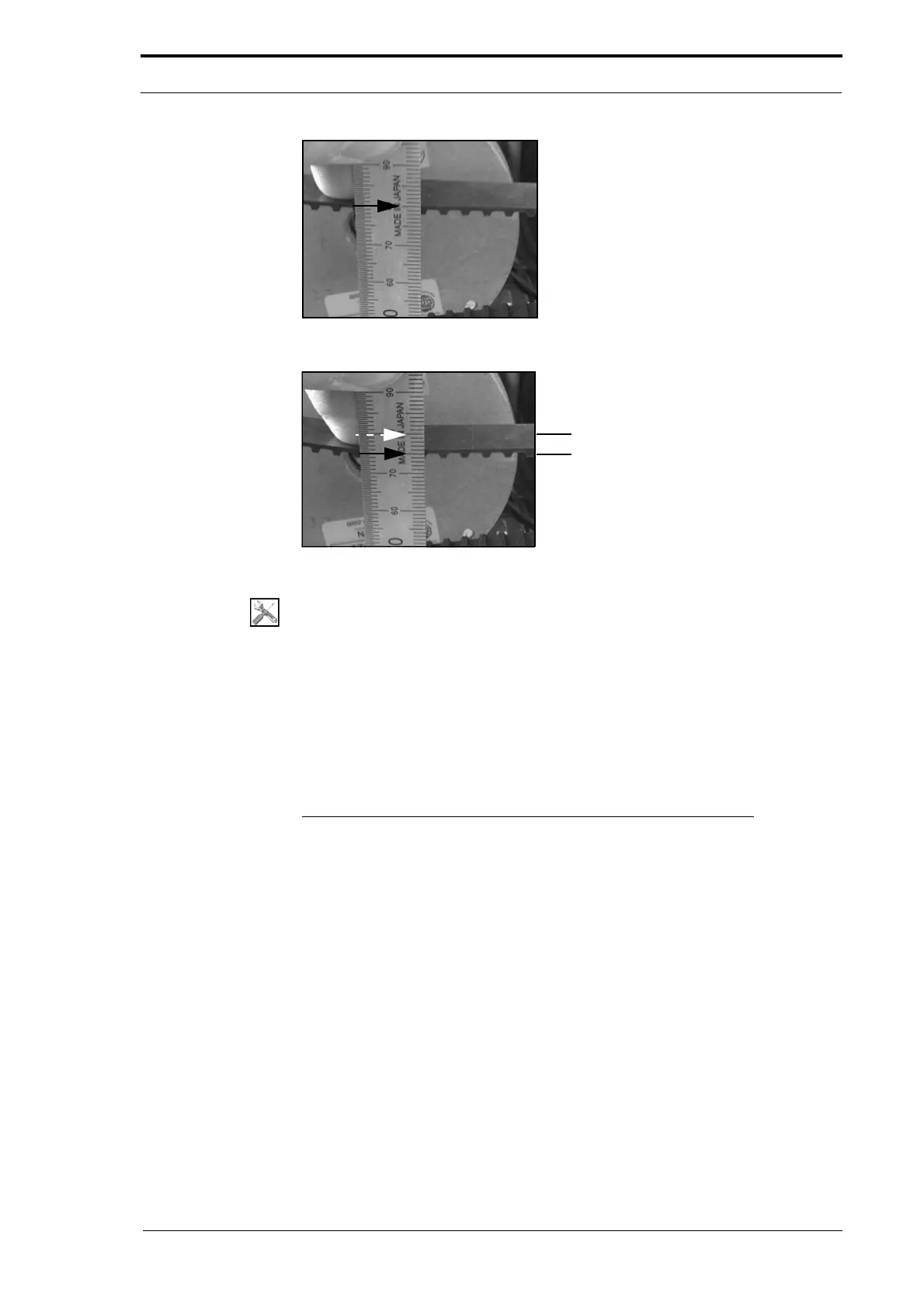

Figure 4.37 First Measurement

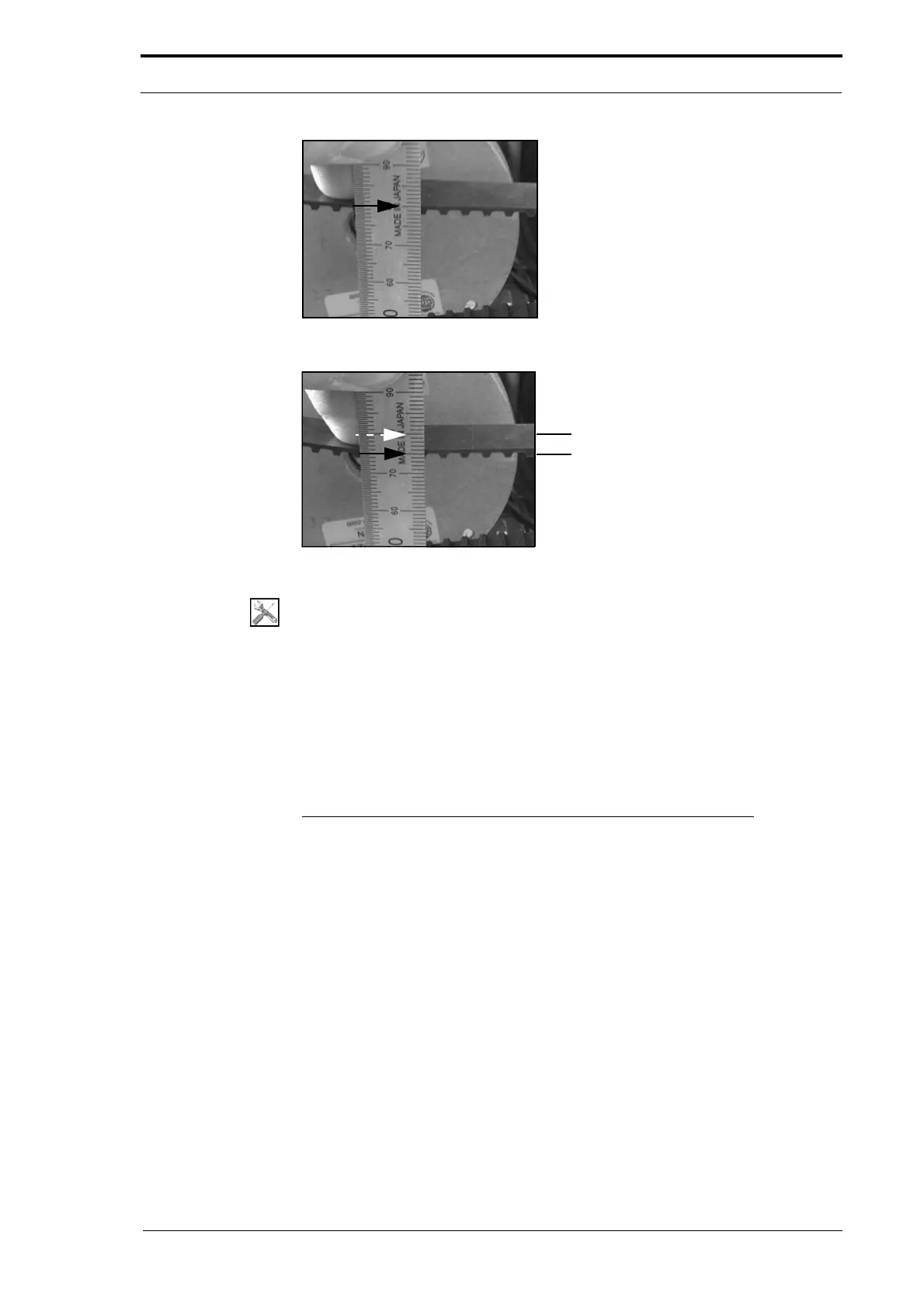

Figure 4.38 Second Measurement

Tools:

• 6” Steel Rule.

Before you start:

• Remove the motor cover (See Section 4.2.2).

(1) Put a 6" steel rule adjacent to the crease-motor belt (see Figure 4.37).

(2) Measure the height of the belt from the motor cover base plate.

(3) Push the belt down as far as is possible (see Figure 4.38).

(4) Measure the height of the belt from the motor cover base plate

The difference between the two height measurements should be 5.0mm.

If the tension on the crease-motor belt is not correct, it must be adjusted (see Section

4.5.12.2).

4.5.12.2 Adjust the Crease-Motor Belt Tension

The top LH screw that attaches the crease-motor

to the RH side plate is installed

through a clearance hole (a circular hole that has a slightly larger diameter than the

diameter of the screw). This screw is known as the pivot screw.

Each of the three remaining screws that attach the crease-motor to th

e RH side plate is

installed through a radial slot (a curved slot that moves around the radius of a fixed

point). This means that the crease-motor can be turned around the pivot screw to

increase or decrease the amount of tension that is applied to the motor belt.

Loading...

Loading...