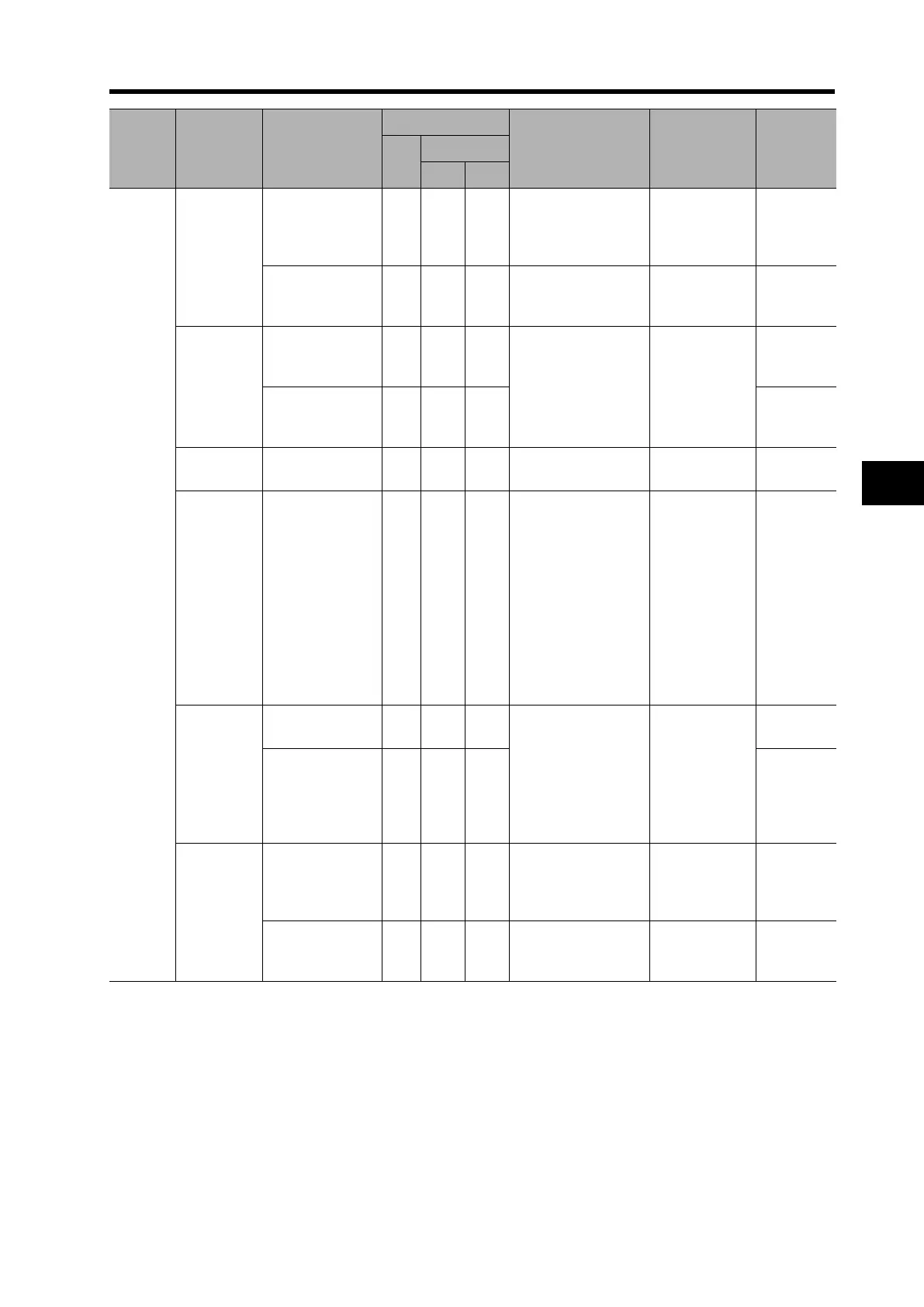

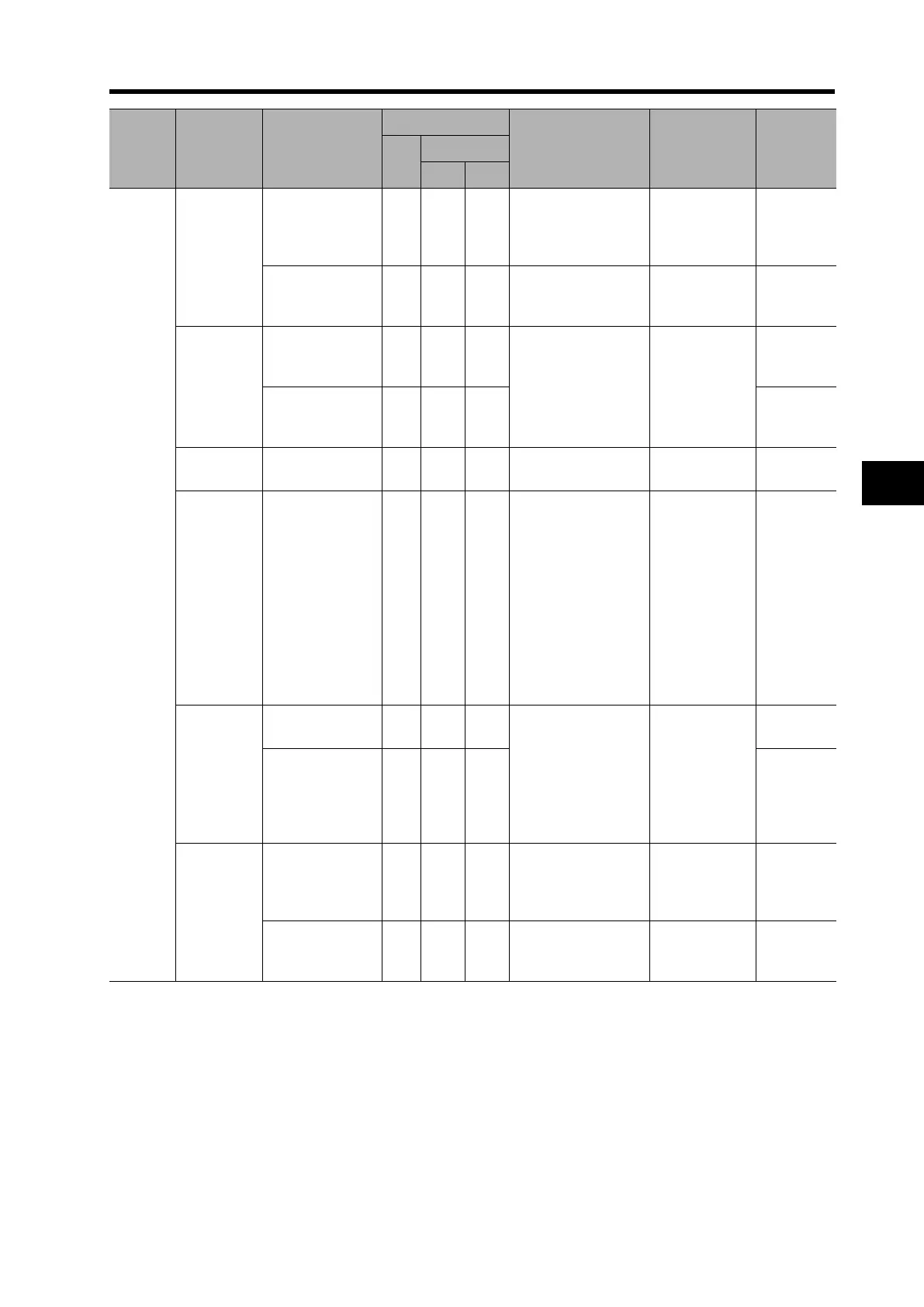

6-4

6-1 Inspection and Maintenance

6

Inspection and Maintenance

Main

circuit

General

Check that any

parts which may

need tightening

are secure.

Tighten securely. No faults

Check that no part

has indications of

overheating.

Visual inspection No faults

Connection

conductor

and wire

Check that there is

no distortion with

the conductor.

Visual inspection No faults

Check that there is

no damage to the

wire Insulation.

Terminal

block

Check that there is

no damage.

Visual inspection No faults

Inverter unit

Converter

unit

(including

the resistor)

Check the

resistance

between the

terminals.

Disconnect the wiring

of the Inverter main

circuit terminal block

and measure the

resistance levels

between terminals

R/L1, S/L2, T/L3 and

P/+, N/-, and between

U/T1, V/T2, W/T3 and

P/+, N/- in the range

of tester ×

1 .

Refer to

"Checking the

Inverter and

Converter".

Inverter unit

replacement

reference

Start/Stop:

Cycle 10

6

*3

Analog

tester

Smoothing

capacitor

Check that there is

no liquid leakage.

Visual inspection

No faults

Reference of

the replacement

period: 10 years

*2 *3

Capacity

meter

Check that the

safety valve has

not come out and

that there are no

bulges.

Relay

Check that there is

no abnormal

sound during

operation.

Acoustic inspection No faults

Check that there is

no rough surface

on the contact.

Visual inspection No faults

Inspection

part

Inspection

item

Inspection point

Inspection period

Inspection method Criteria Meter

Daily

Periodic

1 year 2 years

*1. The life of the smoothing capacitor depends on ambient temperature.

Refer to "Appendix-2 Product Life Curve" for the replacement reference.

*2. The life of the cooling fan varies depending on the environmental conditions, such as ambient temperature

and/or dust. Check the operation through daily inspections.

*3. The replacement reference (year/cycle) or "

Appendix-2 Product Life Curve" is based on the expected design

life, which is not guaranteed.

Loading...

Loading...