Section 7. Component Procedures Model 8210/8250 Maintenance Manual

DC Motors, General Electrical Components

7-84 Publication: 1146945/001, Revised: 25 Sep 2018

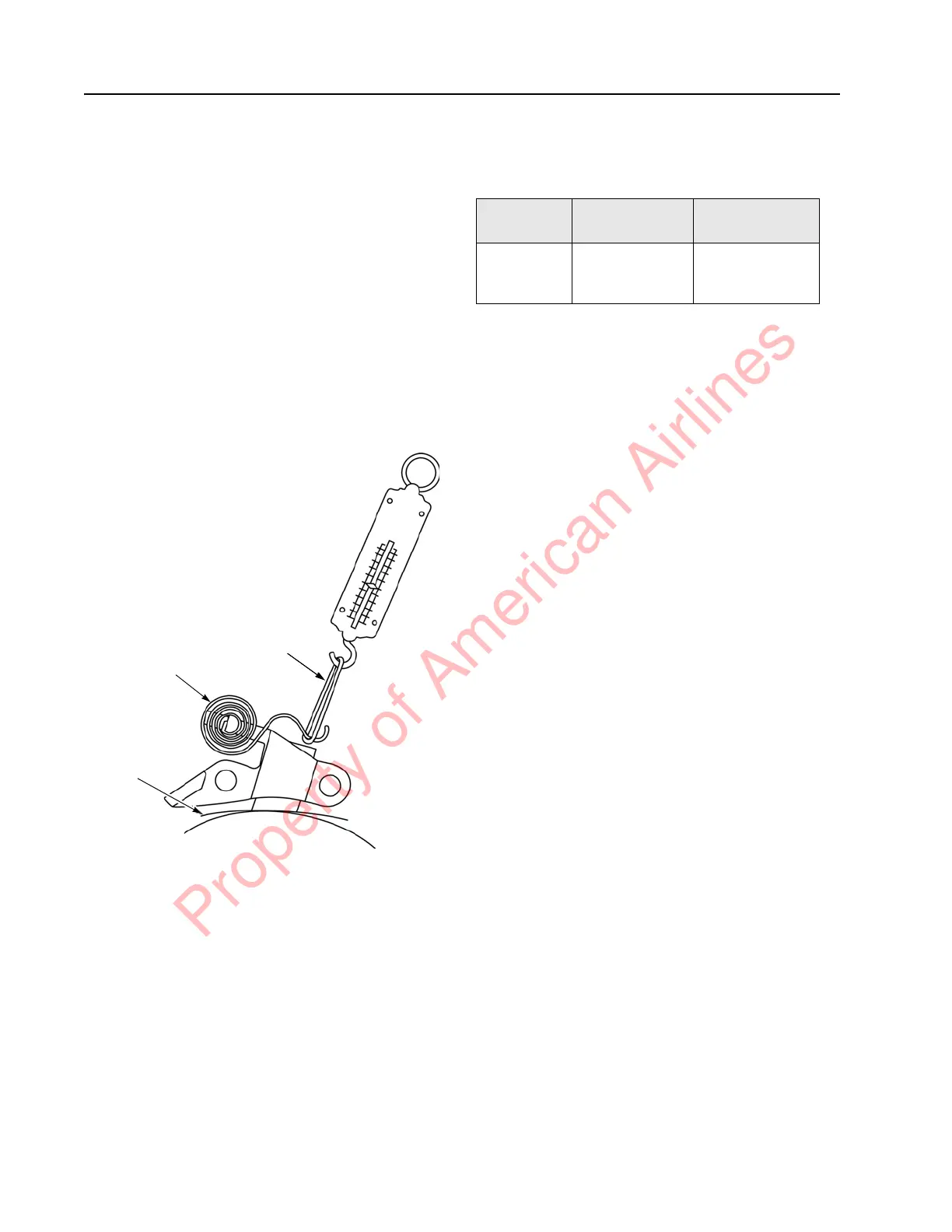

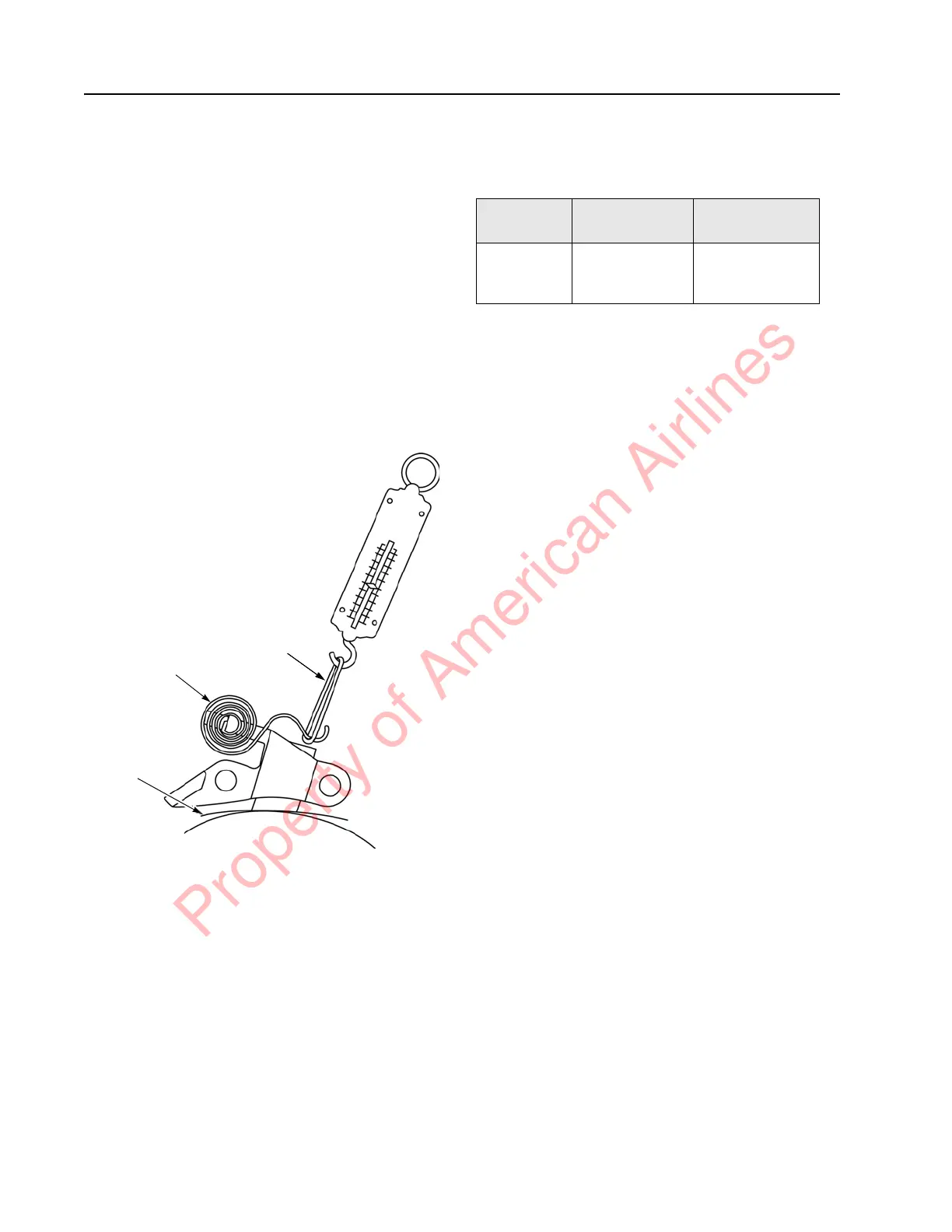

Motor Brush Spring Tension

Brush Spring Tension Inspection

1. If equipped with the optional keypad,

press the red OFF ( O ) key. Place the Main

ON/OFF Switch in the OFF position.

Disconnect the battery connector from the

truck.

2. Remove the lift motor cover.

3. Slide the brush up slightly in its holder.

4. Insert a paper strip between the brush

face and the commutator. See

Figure 7-100.

Figure 7-100. Motor Brush Spring Tension Inspection

5. Place a small leather loop around the coil

spring for the brush. If the brush spring

has a loop at the brush, hook the spring

scale directly to the spring.

6. Attach a 5 lb. (2.27 kg) spring scale to the

leather loop.

7. While gently pulling the scale outward,

slowly pull the paper strip in the direction

that the commutator normally rotates.

8. When the paper strip starts to move freely,

the spring scale reads the spring brush

tension.

9. Refer to the table below for correct spring

tension.

10. Repeat steps 3 through 9 for the

remaining brushes.

Paper

Coil

Spring

Leather

Loop

Motor

Minimum

Brush Length

Spring

Tension

Lift Motor 0.35 in.

(9 mm)

32 to 40 oz.

(908.8 to

1136 grams)

Property of American Airlines

Loading...

Loading...