Model 8210/8250 Maintenance Manual Section 5. Troubleshooting

Symptom Tables: Lift/Lower System

Publication:1146945/001, Revised: 25 Sep 2018 5-19

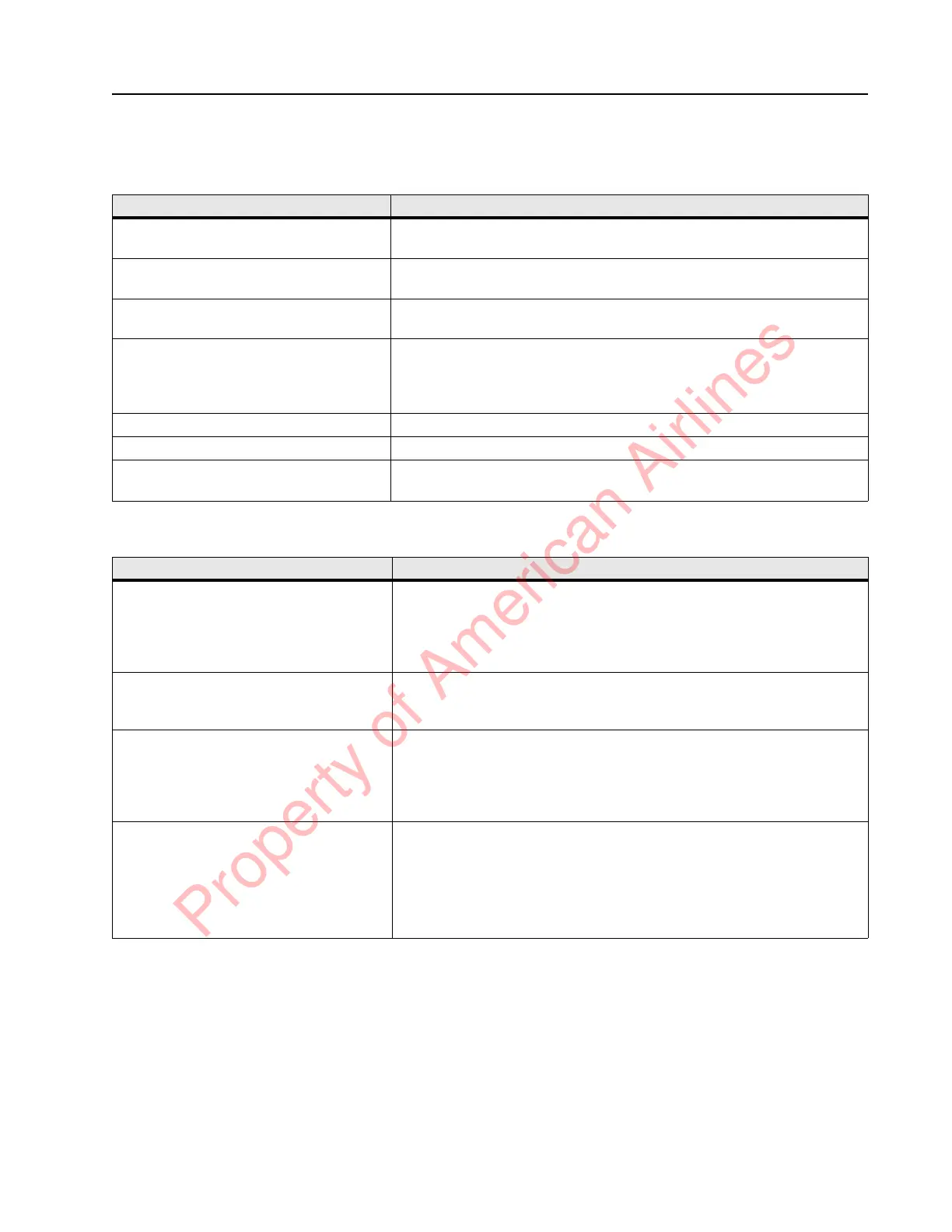

No Lift or Slow Lift, Lift Motor

Does Run

No Lower, Lift and Travel OK

Possible Cause Action

Battery problems Lead acid battery: Replace the battery with a fully-charged battery.

Lithium-ion battery: Check charge status LEDs for charge level.

Mechanical binding in the lift

mechanism

Repair the lift mechanism.

Low hydraulic pressure or relief valve

setting

Check the hydraulic pressure setting and adjust if necessary. See

“Hydraulic Pump Pressure Relief Valve Adjustment” on page 7-103.

Relief valve contaminated or bad.

(Unable to get the correct hydraulic

pressure)

With the main ON/OFF switch OFF and the battery disconnected,

remove the pressure relief valve. Check for damage or

contamination. Replace the valve or flush the system and replace

the hydraulic fluid. See “Hydraulic Fluid” on page 7-95.

Bad lift pump motor or brushes Check the lift pump motor brushes. If OK, replace the pump motor.

Contamination found in the pump Flush the system and replace the hydraulic fluid.

Bad pump If the lift motor is OK, remove the motor from the pump and rotate

the pump by hand. Replace the pump if not OK.

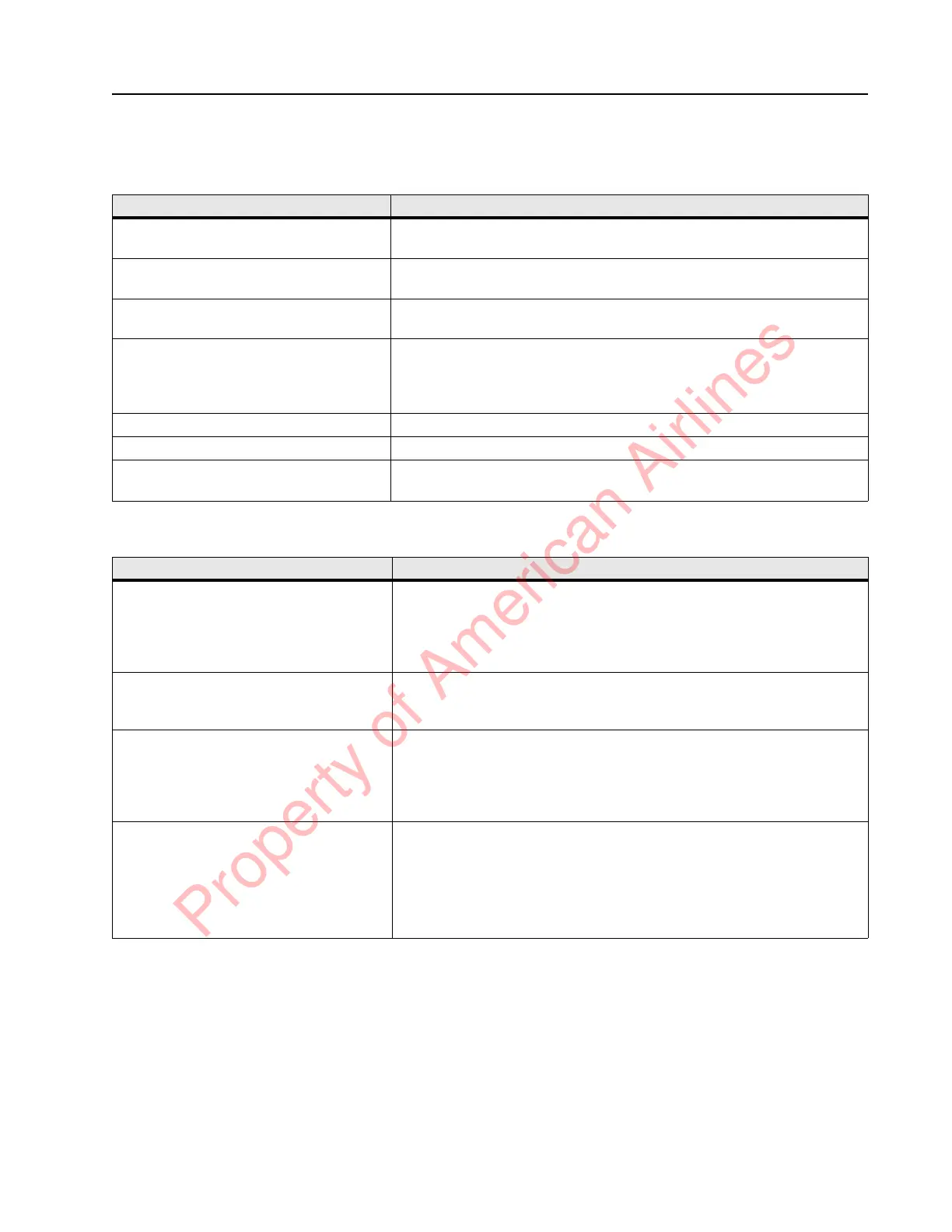

Possible Cause Action

Bad lower solenoid valve... With the main ON/OFF switch ON, cycle the lower switch. Does

the lower solenoid valve energize? If YES, disconnect the battery,

then slowly loosen, but DO NOT REMOVE, the hydraulic line at the

hydraulic pump assembly. Permit the forks to slowly lower. Have

rags and a drain pan ready to catch the fluid.

... if the forks do not lower, check for

mechanical binding in the lift cylinder

or the fork mechanism...

Replace the lift cylinder or repair the lift mechanism.

...if the forks lower, remove and

inspect the solenoid valve...

Inspect for free movement and for signs of contamination. Clean

the solenoid valve or flush the system, clean the filter, and replace

the hydraulic fluid. See “Hydraulic Fluid” on page 7-95.

If no contamination is found, repair or replace the solenoid valve or

the pump assembly.

...check for a bad VM With main ON/OFF switch ON, the PIN-key code entered, the green

ON ( | ) key on the keypad pressed, and the lower button

depressed, check for lower signal input at the CAN (see “Service

Display” on page 3-17). If no signal is detected, replace the VM.

NOTE: Check for mechanical problems in the handle head before

replacing the VM.

Property of American Airlines

Loading...

Loading...