Section 4. Scheduled Maintenance Model 8210/8250 Maintenance Manual

Maintenance Guidelines

4-2 Publication: 1146945/001, Revised: 25 Sep 2018

Maintenance Guidelines

Following a regularly scheduled maintenance

program:

• Promotes maximum truck performance

• Prolongs maximum truck life

• Reduces costly down time

• Prevents unnecessary repairs

Scheduled maintenance includes:

•Lubrication

• Cleaning

• Inspection

• Service

Perform all of the scheduled inspections and

maintenance during the suggested intervals.

The time intervals given in this guide are based

on Deadman Hours (HD) under normal

operating conditions.

When operating under Severe or Extreme

conditions, perform these services more often

as indicated in Table 4-1.

Refer to the “Lubrication Equivalency Chart” on

page A-2 in the Appendix for lubrication

equivalents. Refer to the manufacturer’s

supplements for components not identified in

this manual.

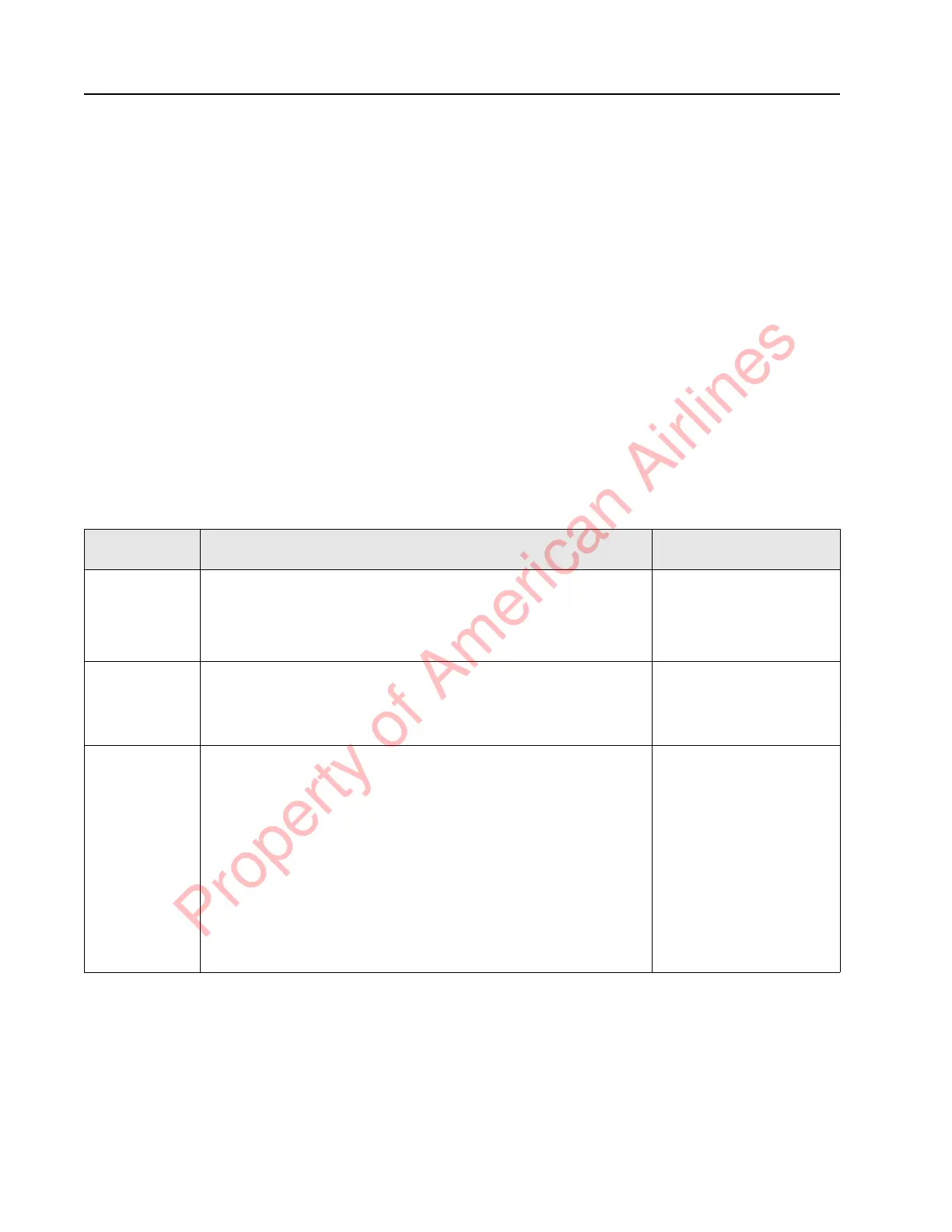

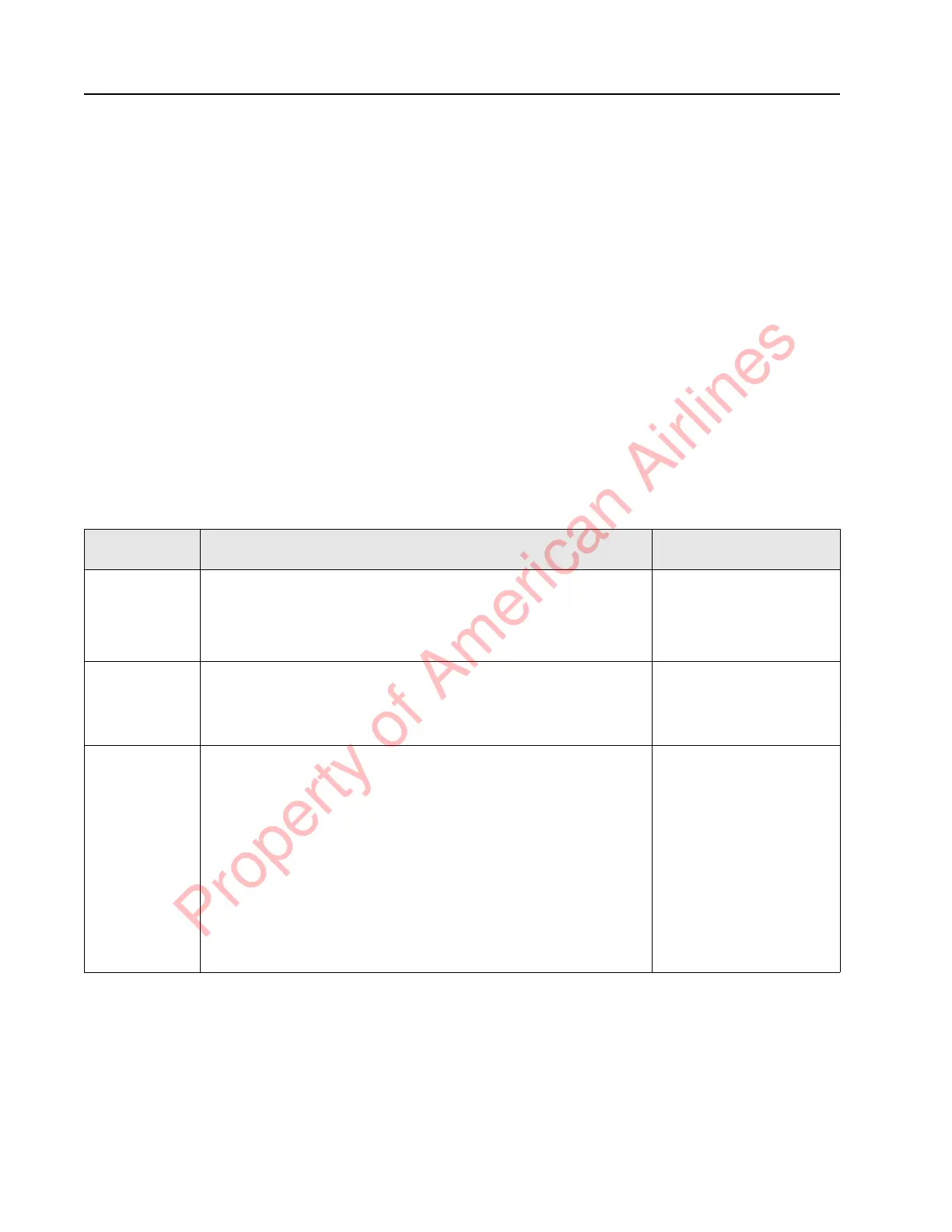

Table 4-1. Maintenance Frequency Table

Operating

Conditions

Working Environment Service Frequency

Light to

Moderate

An eight hour shift of basic material handling First inspection at 90

days or 250 hours and

then every 180 days or

500 hours, whichever

comes first

Severe • Extended heavy duty operation

• Freezer operation

• Sudden temperature changes such as going from freezer to

room temperature

60 days or 250 hours,

whichever comes first

Extreme • All UL Type EE rated lift trucks

• Dusty or sandy conditions such as in cement plants, lumber

or flour mills, coal dust or stone-crushing areas

• High temperature areas such as in steel mills, foundries,

enclosed (Type EE) applications

• Outdoor environments

• Corrosive chemical atmosphere, such as:

• fish, meat or poultry processing plants, tanneries, or any

other similar applications

• chlorine or salt-sea air environments

• Adverse high humidity, wet, damp, or moist conditions

30 days or 100 hours,

whichever comes first

Property of American Airlines

Loading...

Loading...