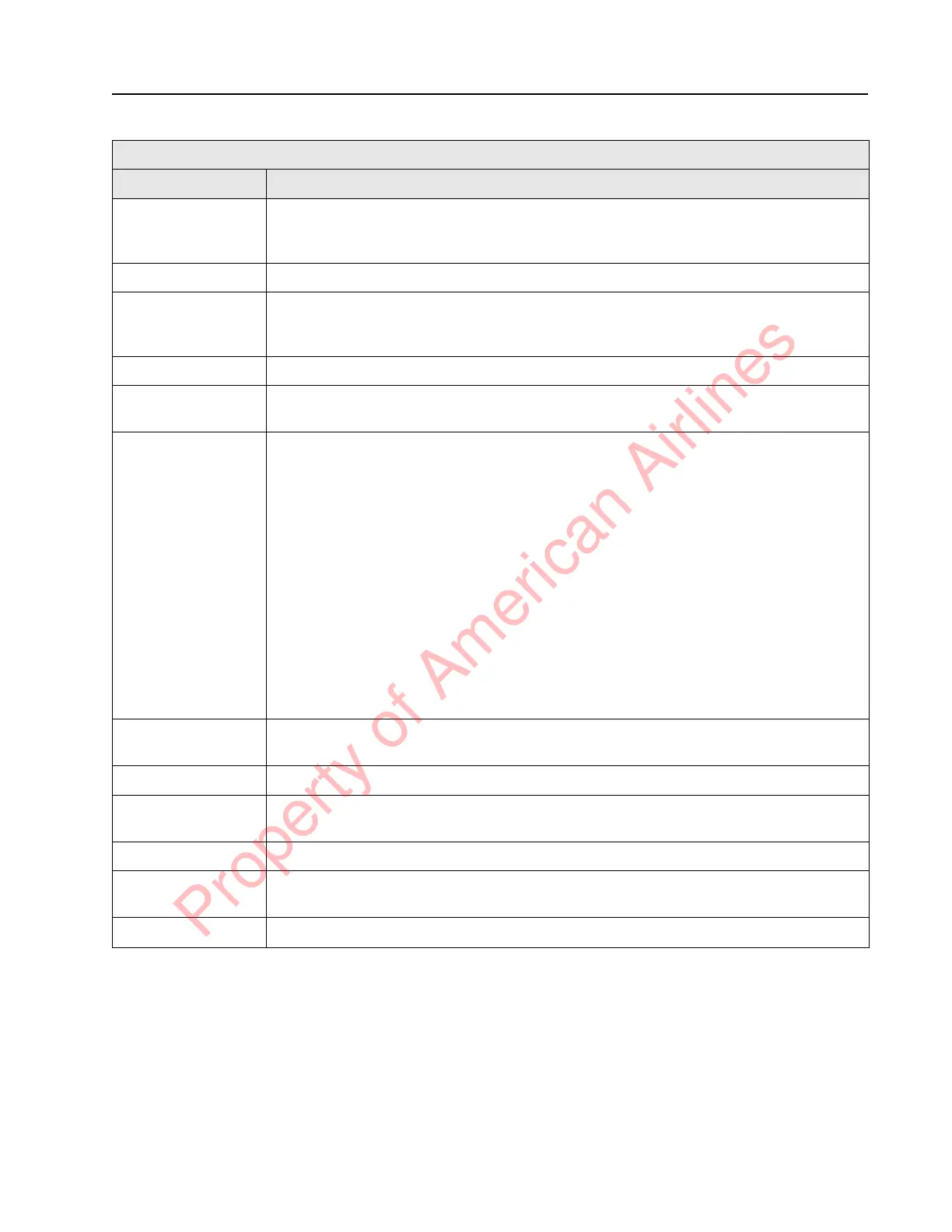

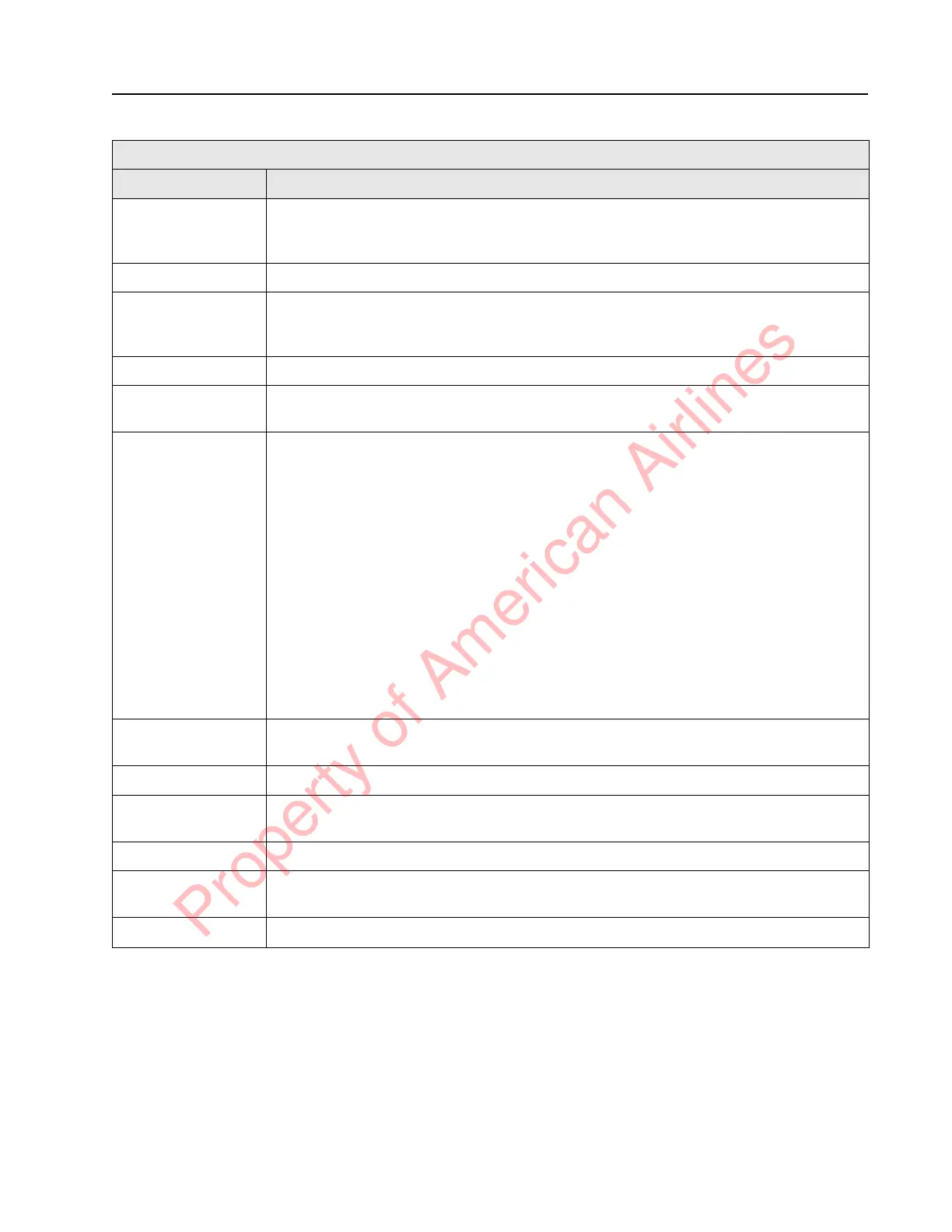

Model 8210/8250 Maintenance Manual Section 4. Scheduled Maintenance

Every 180 Days or 500 Deadman Hours (HD)

Publication:1146945/001, Revised: 25 Sep 2018 4-5

Hardware Check bolt torque of major components (motors, brake, bumper, drive unit, and

hydraulic unit). Tighten any loose hardware. Replace any broken or missing

hardware. See “Appendix” on page A-1.

Horn Check that the horn operates when you press the horn button.

Hydraulic Hoses Inspect all hydraulic hoses for leaks, nicks, cut, chafing, and bulges. Replace

damaged hoses as soon as possible. Inspect all fittings for leaks. Repair any leaks

immediately.

Hydraulic Reservoir Check fluid level. See “Hydraulic Fluid” on page 7-95. Add fluid if necessary.

Lubrication Lubricate all grease points. Lubricate all pivoting shafts on the control handle with

spray lube. See “Grease Fittings” on page 4-7.

Motors AC (traction) - Check the cable lugs to make sure they are tight to the terminal studs.

The outside nut should be torqued to the values listed on page 7-85. Replace any

cable that shows signs of excessive heat. Check sensor wires for sound connection

and condition.

DC (lift) - Visually inspect brushes for excessive heat (discoloration of the pigtails). If

excessive heat is evident, inspect the armature circuit for loose connections. Check

condition of commutator per photos on page 5-9. Find the shortest brush in the

holder. Remove the brush and check overall dimension as per the chart on page 7-83.

Inspect the brush for even wear over the full surface of the brush. If the brush is not

contacting the complete surface, replace the brushes. Inspect the brush rigging for

damage or loose brush holders. Make sure that the connections on the brush leads

are tight. Check brush spring tension per the chart on page 7-84. Blow out the inside

of the motor with compressed air. Check the cable lugs to make sure they are tight to

the terminal studs. Both the inside and outside nut should be torqued to the values

listed on page 7-85. Replace any cable that shows signs of excessive heat.

See “DC Motors, General” on page 7-83.

Shorts to Frame Check for electrical shorts to frame. See “Shorts to Frame Test” on page 5-6. Wipe

down the inside of the compartment.

Switches Check all switches for correct operation and adjust as needed.

Ventilation Slots Make sure ventilation slots in the tractor grille cover are clear of obstructions and

debris.

Warning Decals Replace any unreadable or damaged decals.

Load Wheels and

Drive Tires

Examine for bond failure, chunking, and excessive or uneven wear. Inspect the load

wheel bearings for binding or excessive play. Apply grease.

Casters (Optional) Examine tire for condition. Verify that tires rotate freely.

Perform the following maintenance tasks every 180 days or 500 HD, whichever comes first.

Component Task

Property of American Airlines

Loading...

Loading...