Section 5. Troubleshooting Model 8210/8250 Maintenance Manual

DC Electric Motors

5-10 Publication: 1146945/001, Revised: 25 Sep 2018

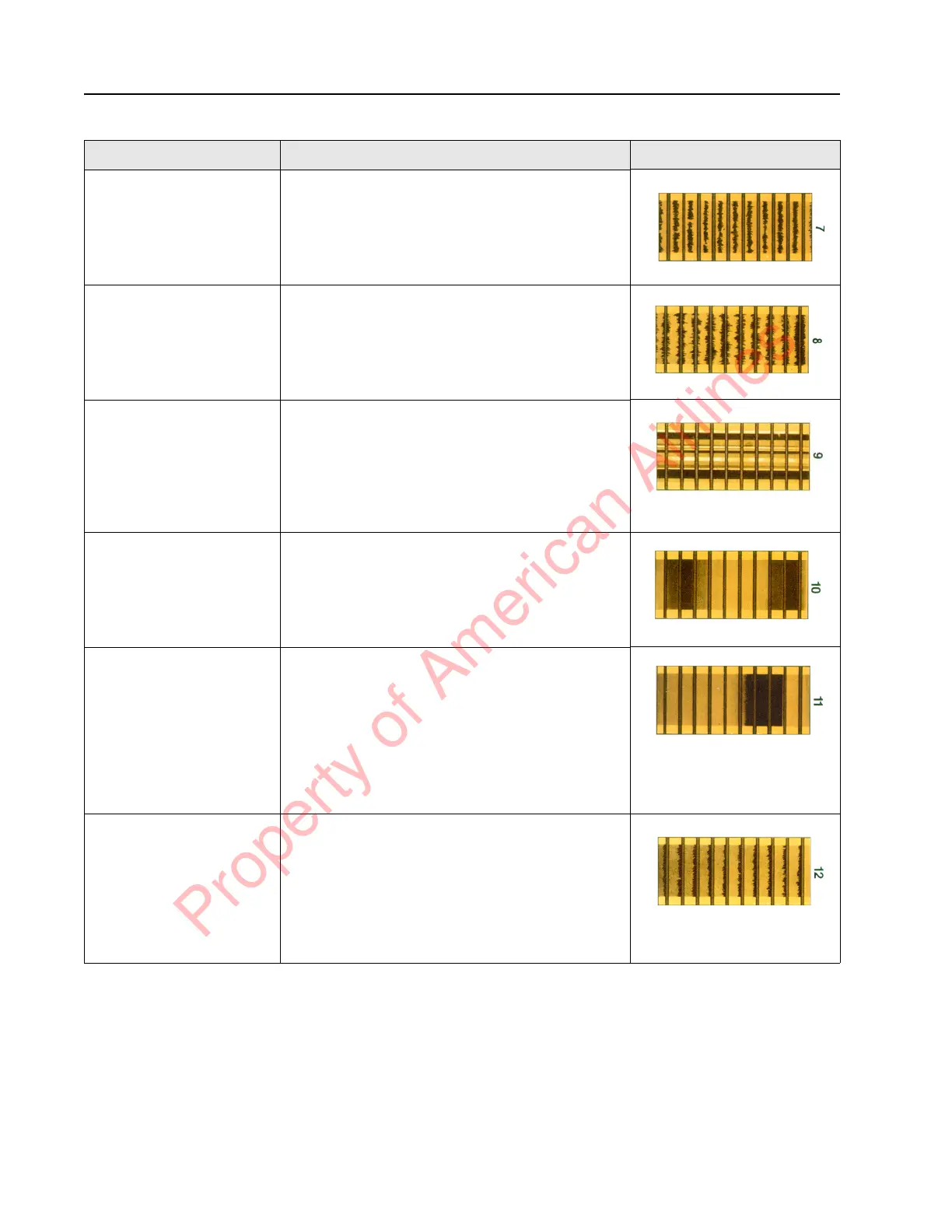

Unsatisfactory

Condition-Example of

Incorrect Commutator

Machining

Bars are low on entry and leaving edges causing

the brushes to ride on the middle of the bars.

Continued use may result in failure and damage

to other systems. The motor should be replaced

or recut at a qualified repair facility. Consider

more frequent scheduled maintenance intervals.

Brushwear07.tif

Unsatisfactory

Condition-Example of

Incorrect Commutator

Machining

Bars are low in the middle causing the brushes to

ride on the entry and leaving bar edges.

Continued use may result in failure and damage

to other systems. The motor should be replaced

or recut at a qualified repair facility. Consider

more frequent scheduled maintenance intervals.

Brushwear08.tif

Unsatisfactory

Condition-Streaky Film

With Commutator Wear

This is a further development of the third

example. Earlier corrective action should have

been taken. Continued use may result in failure

and damage to other systems. The motor should

be replaced or recut at a qualified repair facility.

Consider more frequent scheduled maintenance

intervals.

Brushwear09.tif

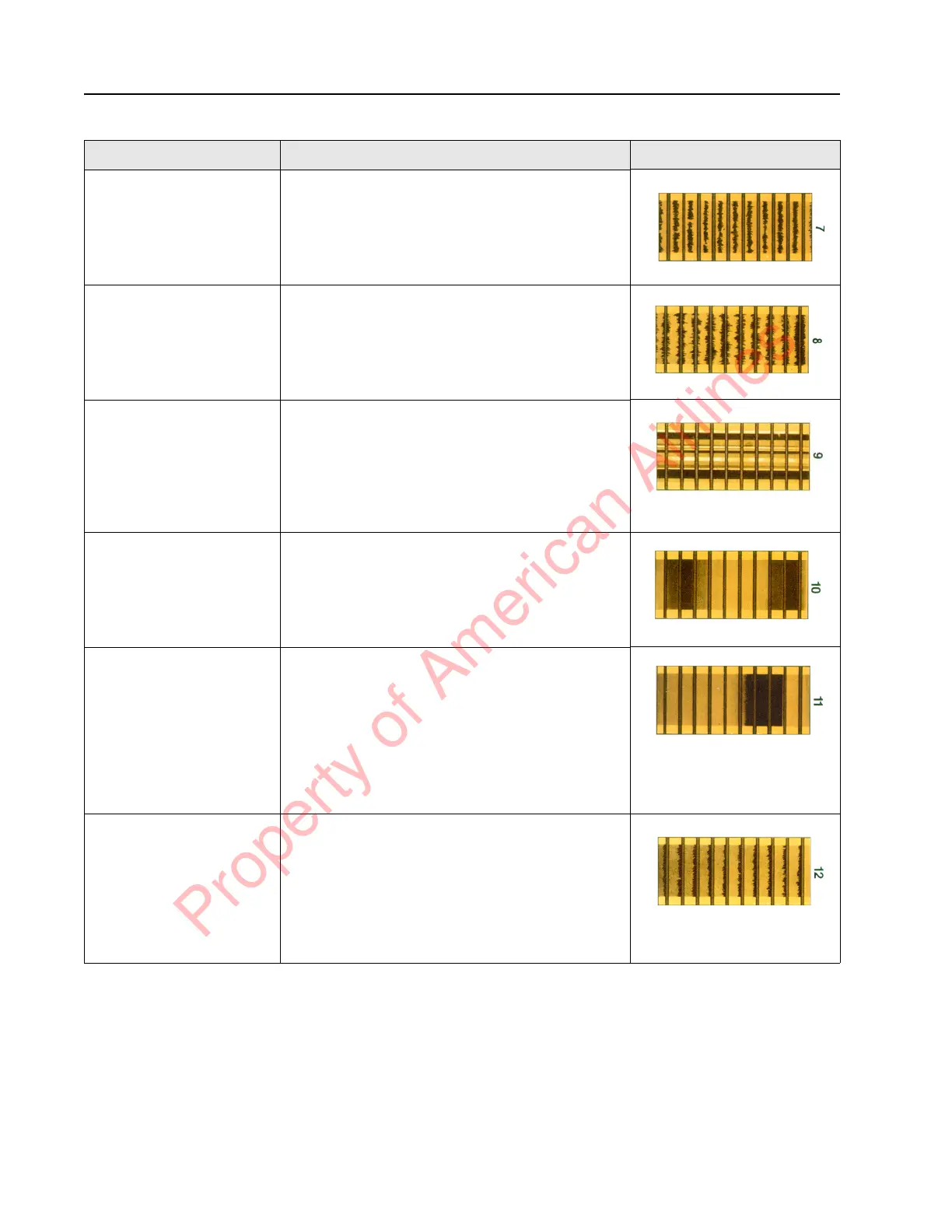

Unsatisfactory

Condition-Double Pole

Pitch

Darkening of commutator in sequences two pole

pitches apart. This condition may result from an

armature fault or some other fault. Continued

use may result in failure and damage to other

systems. The motor should be replaced or recut

at a qualified repair facility.

Brushwear10.tif

Unsatisfactory

Condition-Brush Contact

Mark

This condition may result from storage of the

machine for long periods with brushes in

position. It may also result from operation in

prolonged stall conditions. Storage marks are

easily removed with a polishing stone, see

“Polishing the Commutator” on page 7-85. Stall

marks should be cleaned and inspected for

damage or shorts. The motor should be replaced

if damage has occurred.

Brushwear11.tif

Unsatisfactory

Condition-Bar Edge

Burning-Cause High Mica

This condition is caused by high mica in every

slot and can be caused by incorrect or excessive

stoning. The same effect can occur on one bar

only. Chattering or loud operation may also be

noticed. Continued operation will result in

increased brush wear and may result in

commutator damage. The motor should be

replaced or recut at a qualified repair facility.

Brushwear12.tif

Condition Probable Cause Commutator Surface

Property of American Airlines

Loading...

Loading...