Operating instructions Chapter 12

S3000

8009942/WK81/2012-11-28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 153

Subject to change without notice

Technical specifications

Minimum Typical Maximum

OSSDs

Output signal switching device pair 2 PNP semiconductors, short-circuit

protected

4

0)

, cross-circuit monitored

Safe state in case of an error At least one OSSD is in the LOW state

HIGH switching voltage at 500 mA V

S

– 2.7 V V

S

Switching voltage LOW 0 V 0 V 3.5 V

Source switching current 6 mA 0.2 A 0.5 A

Leakage current

41)

250 µA

Load inductance

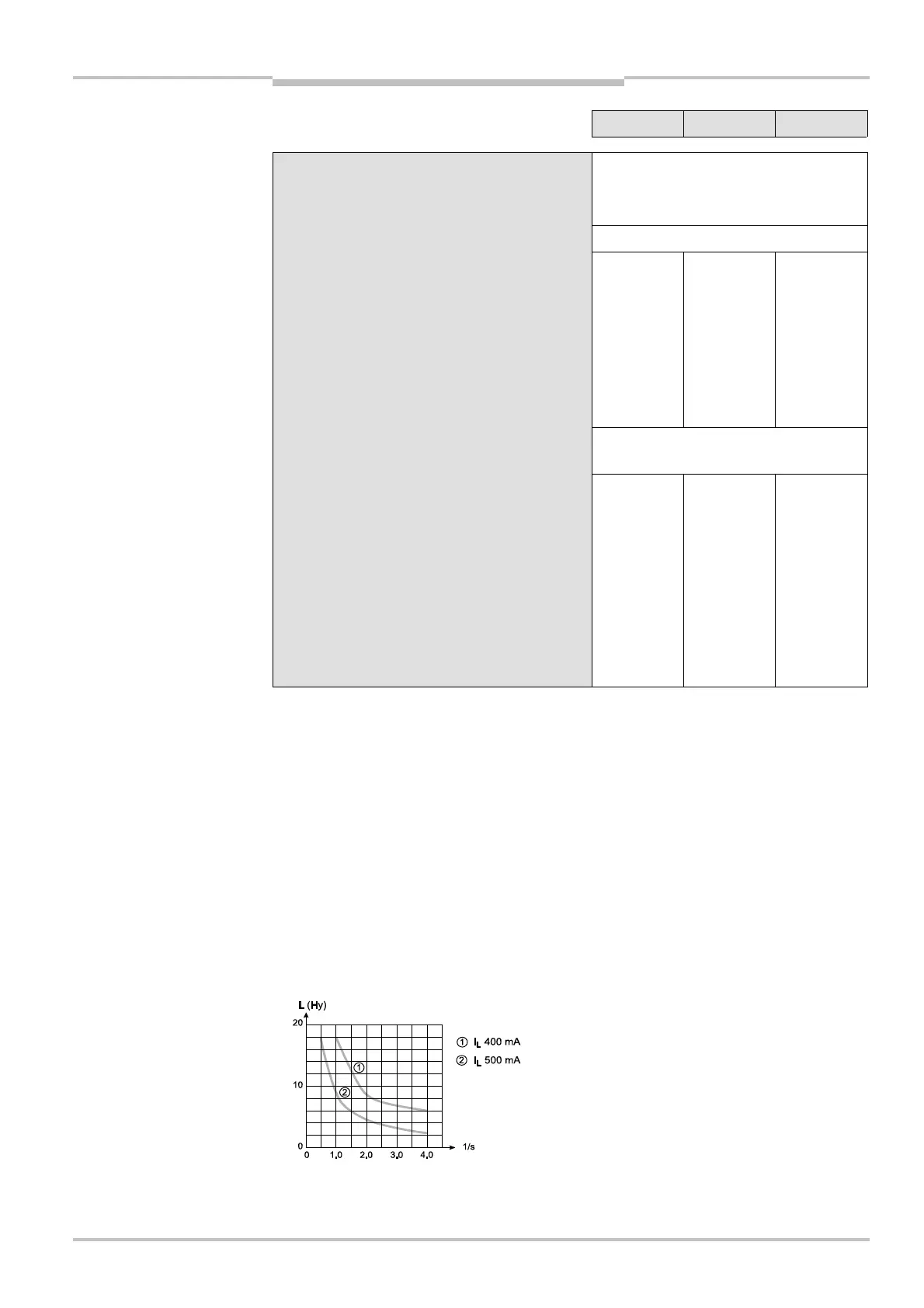

42)

2.2 H

Load capacity 2.2 µF at

50 b

Switching sequence (without switching and

without simultaneous monitoring)

Depending on load inductance

Permissible cable resistance

43)

2.5 b

Test pulse width

44)

230 µs 300 µs

Test frequency

at 0.5° angular resolution

At 0.25° angular resolution

120 ms

240 ms

Power-up delay of the OSSDs from red to

green

120 ms

Time offset on switching the OSSDs between

OSSD2 and OSSD1

1.3 ms 2 ms

40)

Applies to the voltage range between V[0]

S

and 0 V.

41)

In the case of a fault (0 V cable open circuit) maximally the leakage current flows in the OSSD cable. The

downstream controller must detect this status as LOW. A FPLC (fail-safe programmable logic controller) must

be able to identify this status.

42)

The maximum rated load inductance is higher with lower switching sequence.

43)

Make sure to limit the individual line core resistance to the downstream controller to this value to ensure that

a cross-circuit between the outputs is safely detected. (Also note EN 60204<1.)

44)

When active, the outputs are tested cyclically (brief LOW). When selecting the downstream controllers, make

sure that the test signals do not result in deactivation.

Loading...

Loading...