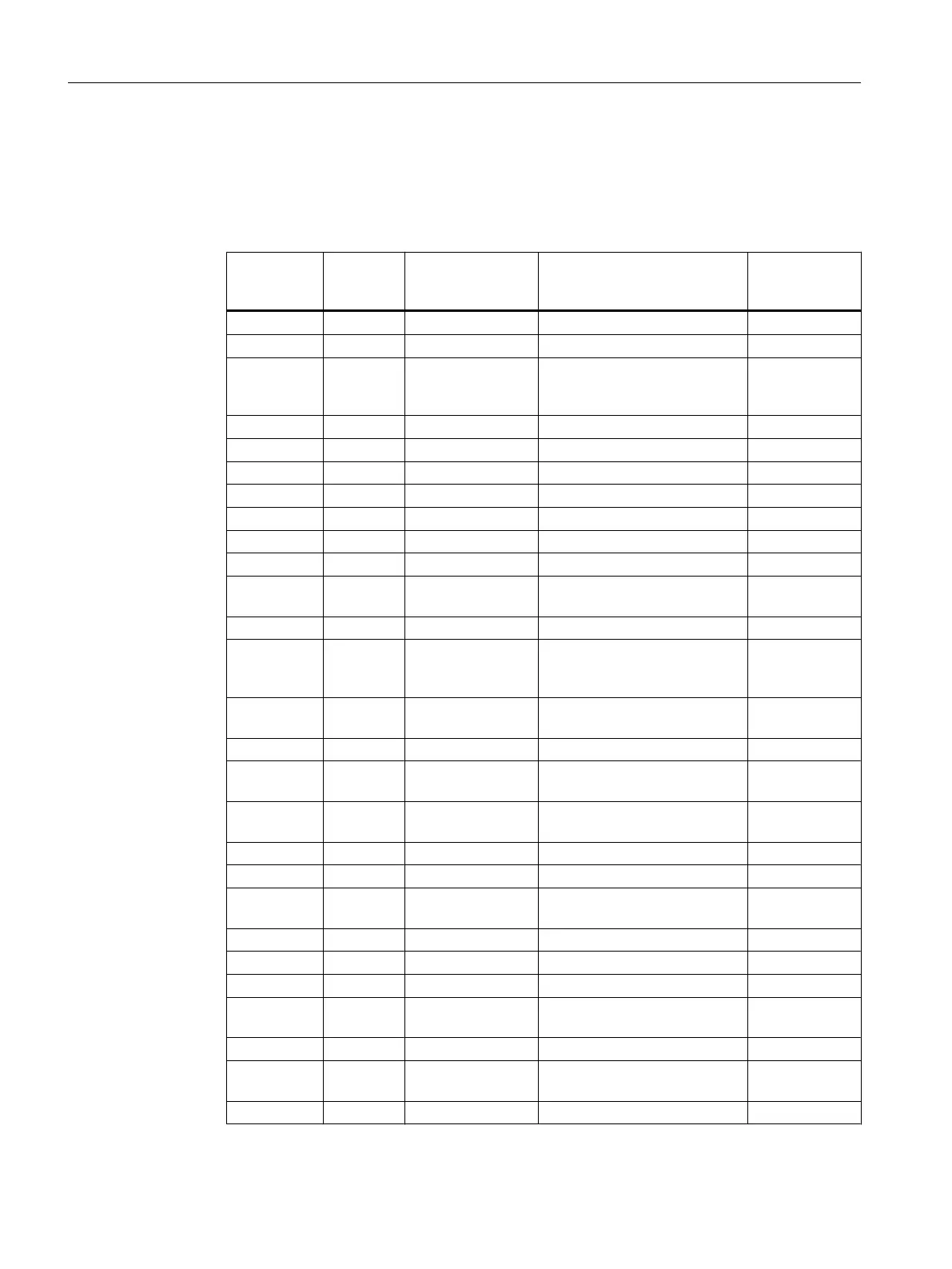

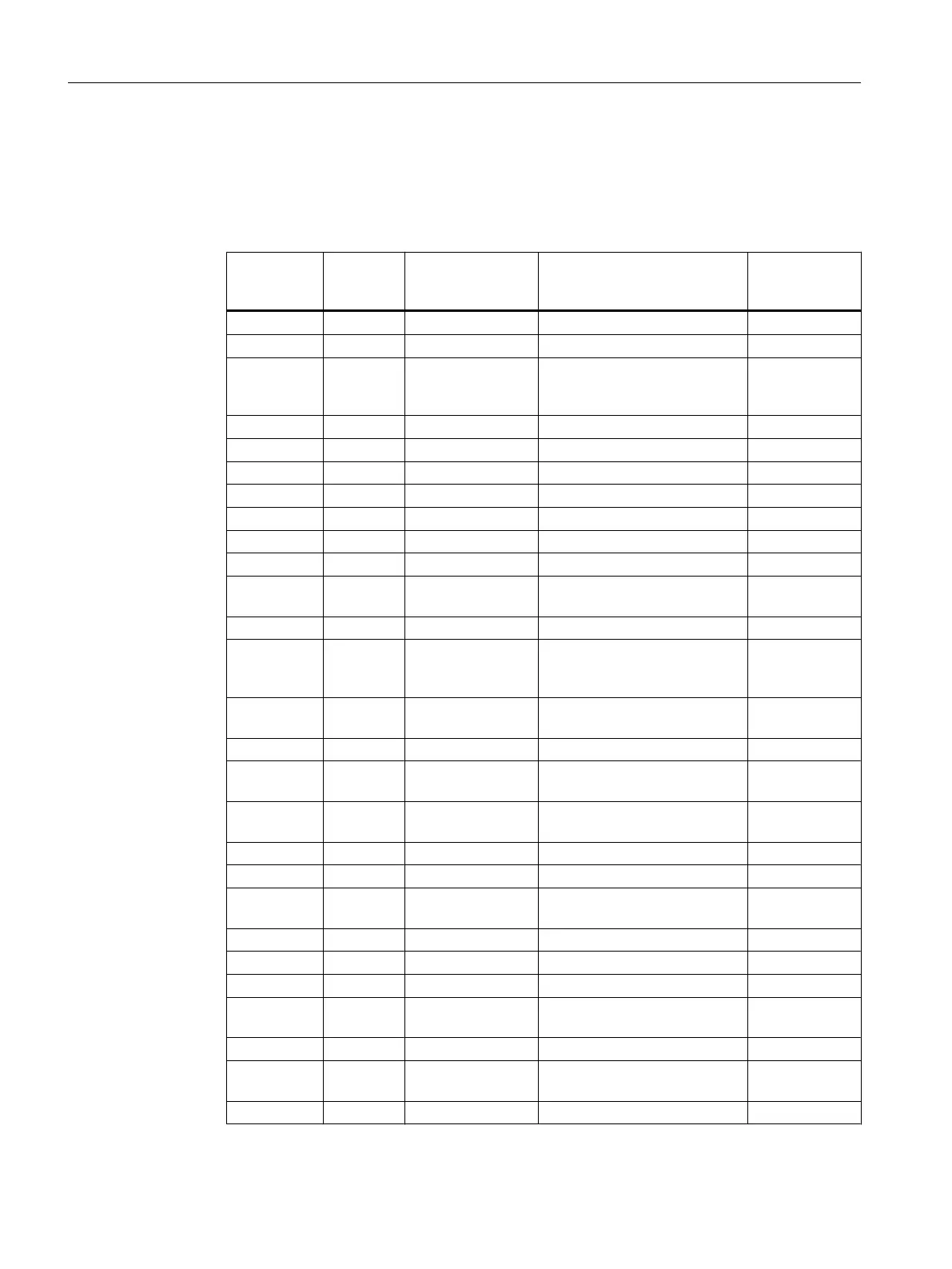

Procedure

1. Open the "General" tab and "Inputs/Outputs" tab in the "Object Properties" dialog box for

each block.

2. Enter the parameters for all blocks according to the table below.

Block Block

name in

the project

I/O Meaning Value

Mul04 4 In1.ST Value 1 to multiply (BYTE) 0

In1.Value Value 1 to multiply (REAL) 0

In4.Value Invert sign for flow rate (proc‐

ess value) - Part of the fill level

simulation in raw materials tank

-1.0

Pcs7AnIn INPUT_U Feature.Bit29 Enables a substitute value 1

Mode Measuring range 4 to 20 mA 16#0203

Scale.High High measuring range 550

SimOn.Value Simulation value active 1

SimPV_In.Value Raw materials tank level 500

SubsPV_In Substitute value for SimPV_In 500

Integral INT_P In.ST Analog input value (BYTE) 0

In.Value Simulation of the raw material

tank level

0.0

OutHiLim High limit of the output value 500

OutTrk.ST Predefined value used for Out‐

TrkOn = 1 (BYTE)

0

OutTrk.Value Predefined value used for Out‐

TrkOn = 1 (REAL)

0

TI Integration time 30

MonAnL LIA GradHDnEn Gradient monitoring (high) for

negative changes

0

GradHUpEn Gradient monitoring (high) for

positive changes

0

PV.ST Process value (BYTE) 0

PV.Value Process value (REAL) 0

PV_AH_En PV alarm limit (high) deactiva‐

ted

0

PV_AH_Lim High alarm limit = 490 m

3

490

PV_AL_Lim Low alarm limit = 5 m

3

25

PV_Hyst Hysteresis 1

PV_OpScale.High High display limit of the proc‐

ess value in the container

550

PV_Unit Unit of the PV in m3 1034

PV_WH_En PV warning limit (high) deacti‐

vated

0

PV_WH_Lim High warning limit = 450 m

3

450

Creating CFCs

6.6 Working with the CFC Editor

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

90 Getting Started, 12/2017, A5E42181435-AA

Loading...

Loading...