03.2010

Siemens AG 6SE7087-6QX70 (Version AL)

SIMOVERT MASTERDRIVES Compendium Motion Control 9

Number / Fault Cause Counter-measure

F085

Add. CB initialization

fault

A fault has occurred during initialization of the

CB board.

Fault value r949:

1: Board code incorrect

2: TB/CB board not compatible

3: CB board not compatible

5: Error in configuration data

6: Initialization timeout

7: TB/CB board double

10: Channel error

Check the T300 / CB board for correct

contacting and check the CB initialization

parameters:

- P918.02 CB Bus Address,

- P711.02 to P721.02 CB Parameters 1 to 11

F087

SIMOLINK initialization

fault

A fault has occurred during initialization of the

SLB board.

- Replace CU (-A10), or replace the unit

(Compact PLUS type)

- Replace SLB

F099

Friction characteristic

record

Recording of the friction characteristic was

interrupted or not done at all.

Fault value r949 gives the cause (bit coded):

Bit Meaning Value displayed

0 Pos. speed limit 1

1 Neg. speed limit 2

2 Releases missing: 4

direction of rotation, inverter, controller

3 Speed controller connecting 8

4 Interrupt through cancellation of the 16

record command

5 Illegal dataset changover 32

6 Time exceeded 64

7 Measuring error 128

F109

Mld R(L)

The rotor resistance determined during

measurement of the direct current deviates too

greatly.

- Repeat measurement

- Enter data manually

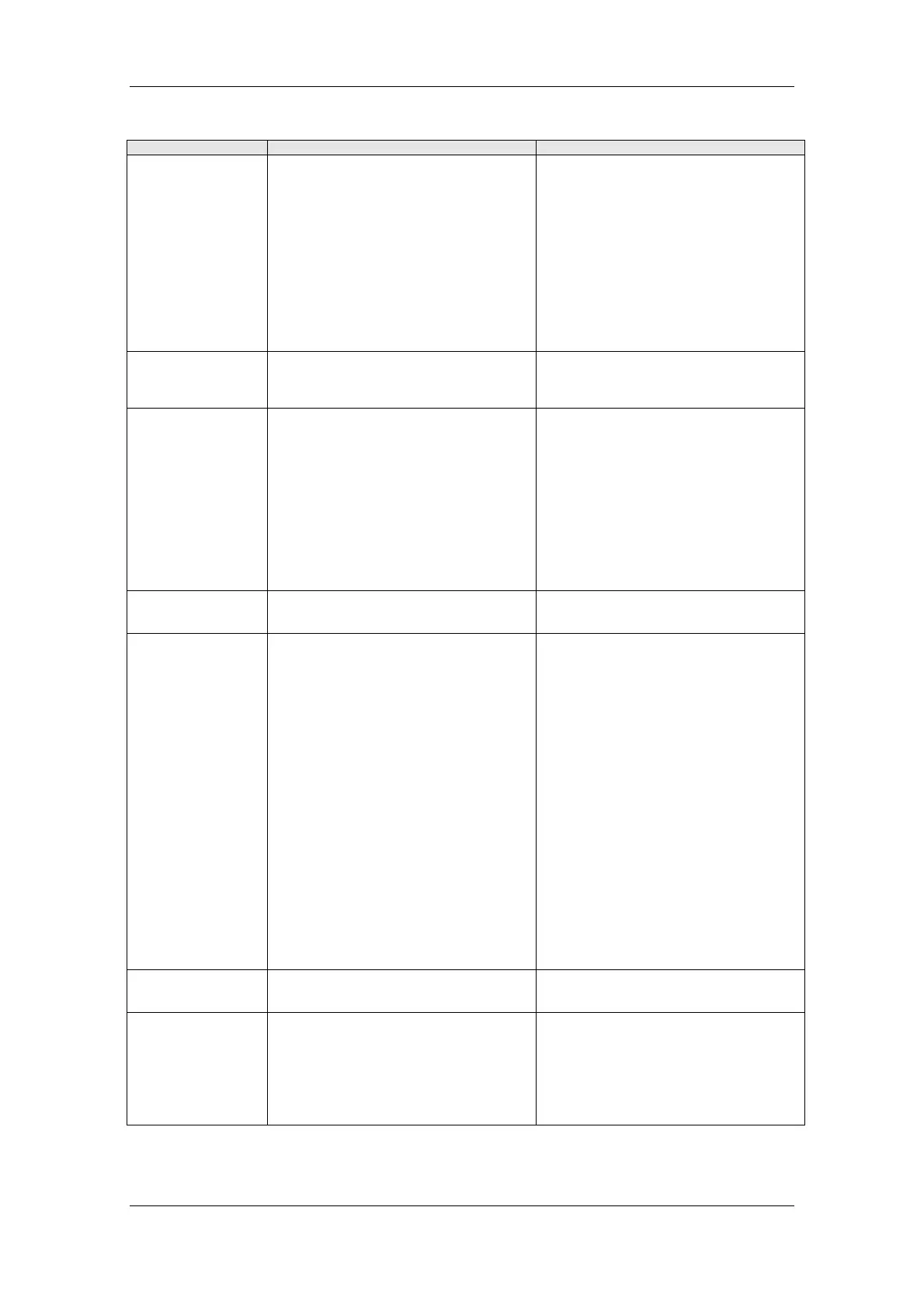

F111

MId DSP

A fault has occurred during the Mot Id.

r949=1 The current does not build up when

voltage pulses are applied

r949=2 (only for P115=4) The difference

between speed setpoint and actual value is

too large during measurement

r949=3 (only for P115=4) The magnetizing

current determined is too high.

r949=4 (only for P115=4) Two phases of the

motor or the a/b tracks of the encoder were

swapped when they were connected.

r949=121 The stator resistance P121 is not

determined correctly

r949=124 The rotor time constant P124 is

parameterized with the value 0 ms

r949=347 The valve voltage drop P347 is not

determined correctly

- Repeat measurement

- When r949=1 Check motor cables

- When r949=2 Avoid mechanical stressing of

the motor during the measurement; if the fault

occurs directly after the start of the motor

identification check the encoder and motor

cables.

- When r949=3: Check the motor rating plate

data stored (ratio Vrated / Irated does not

correspond with the measured inductance)

F112

Mid X(L)

A fault has occurred during measurement of

the motor inductances or leakages.

- Repeat measurement

F114

MId OFF

The converter has automatically stopped the

automatic measurement due to the time limit

up to power-up having been exceeded or due

to an OFF command during the measurement,

and has reset the function selection in P115.

Re-start with P115 function selection = 2

"Motor identification at standstill".The ON

command must be given within 20 sec. after

the alarm message A078 = standstill

measurement has appeared.

Cancel the OFF command and re-start

measurement.

Loading...

Loading...