Communication / PROFIBUS 09.2008

6SE7087-6QX70 (Version AK) Siemens AG

8.2-106 Compendium Motion Control SIMOVERT MASTERDRIVES

8.2.9.7 Communication interface

P918: Node address

Value range 0 – 125 (126 is reserved for start-up purposes)

The node addresses 0, 1 and 2 are generally occupied by master

and configuration tools and therefore should not be used for

slaves on the PROFIBUS. Address 3 is the first appropriate node

address to be used for a slave on the PROFIBUS.

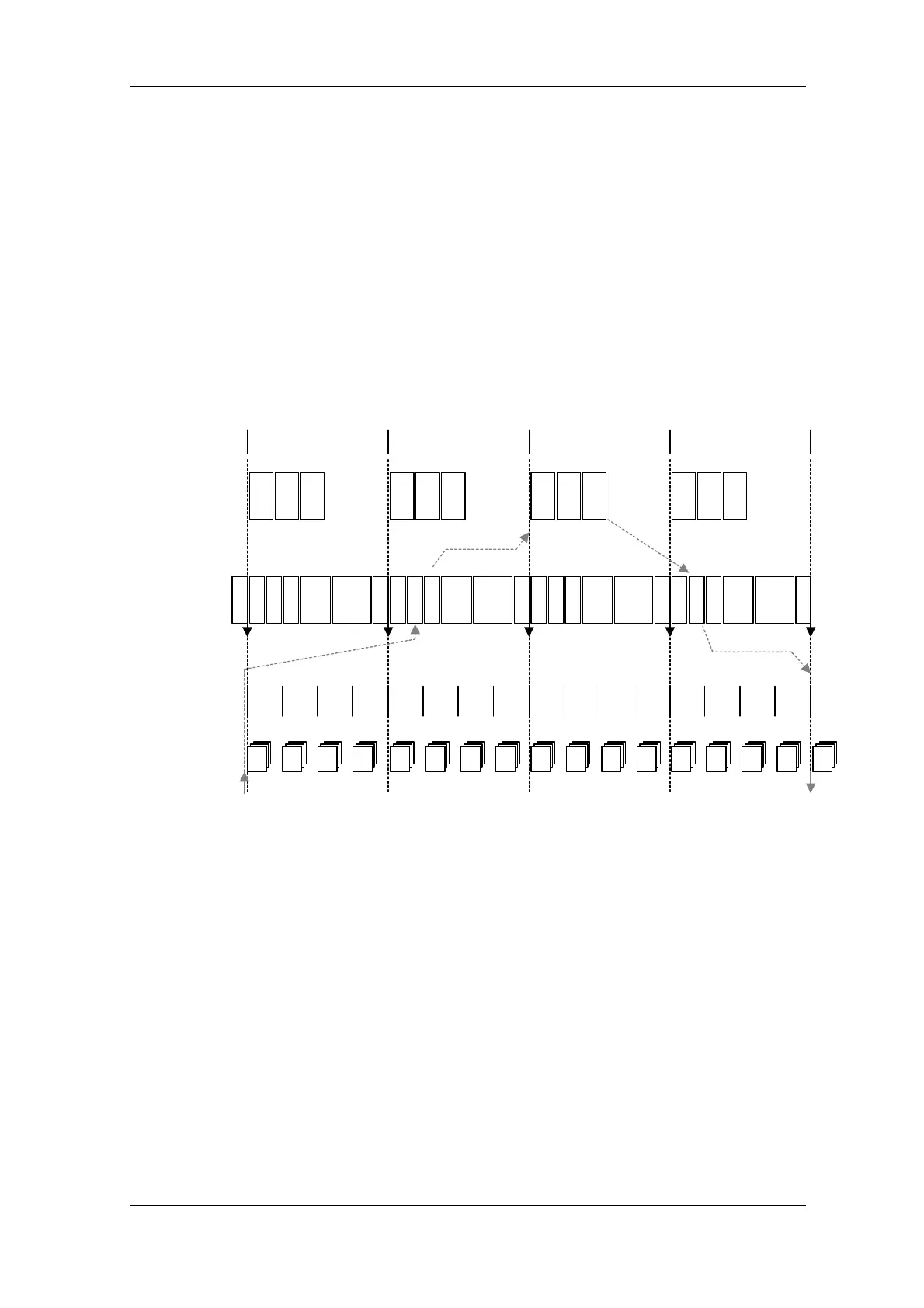

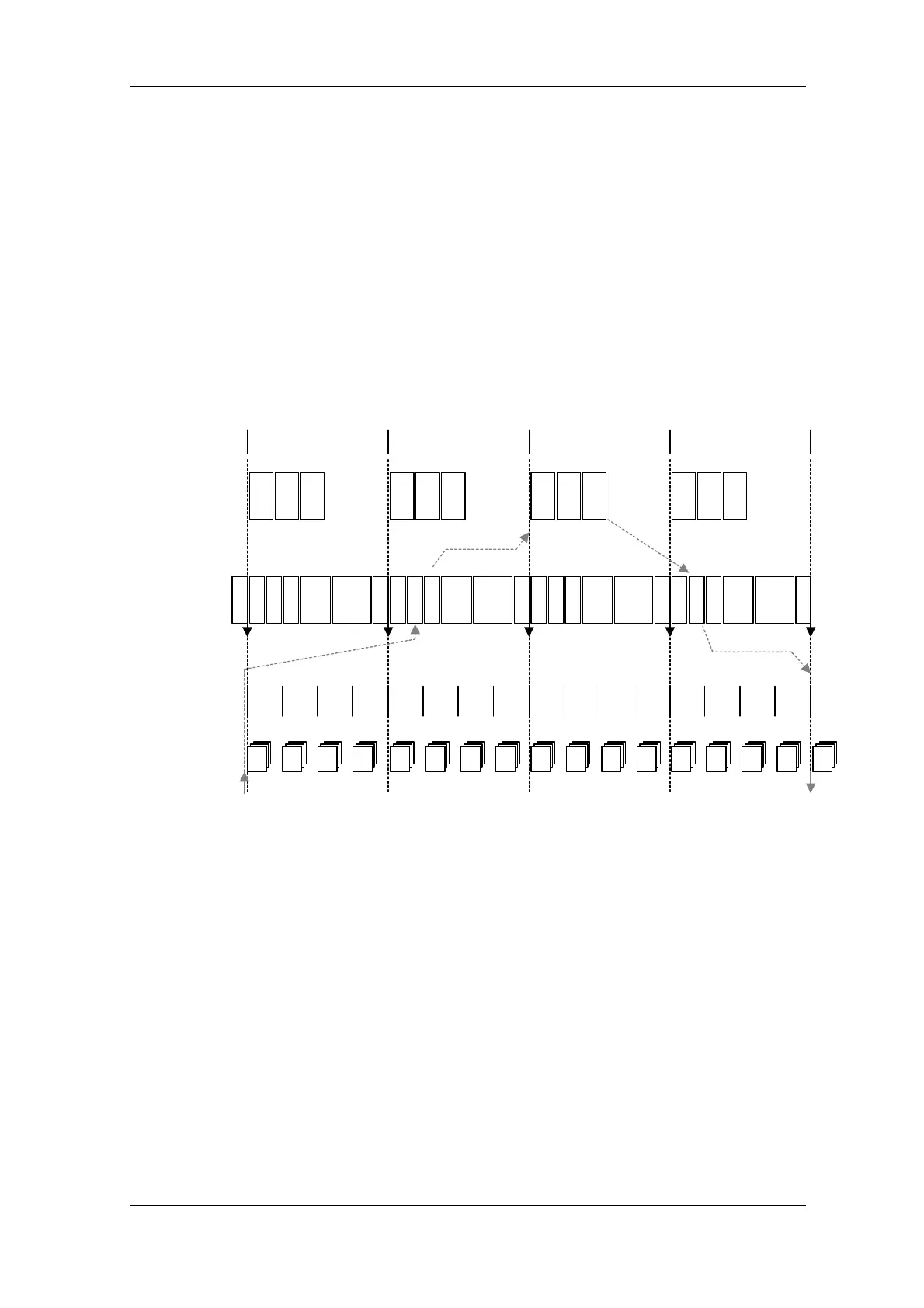

8.2.9.8 Clock synchronous application

Course of an isochronous DP cycle

Example (simplest DP cycle, standard case for MASTERDRIVES)

Master

DP cycle

Speed/current

controller clock

time

T

SAPC

Slave 1...3

ReserveT S1 S2 S3

MSG

T ReserveS1 S2 S3

MSG

T ReserveS1 S2 S3

MSG

T ReserveS1 S2 S3

MSG

T

R1 R2 R3 R1 R2 R3 R1 R2 R3 R1 R2 R3

R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1

T

I

= 0 T

O

= 0

Pos Controller

clock time

(T

MAPC

)

T

M

= 0

Fig. 8.2-37 Example: simplest DP cycle

In this example four DP cycles are needed for a response in the position

control circuit.

♦ 1. Actual value recording (in slave)

♦ 2. Actual value transmission (slave -> master)

♦ 3. Position controller (in master)

♦ 4. Setpoint transmission (master -> slave)

This model makes few demands on the computing output of the master,

but leads to an increase in the control-specific dead time:

Dead time = 4 * T

DP

.

Node address

Loading...

Loading...