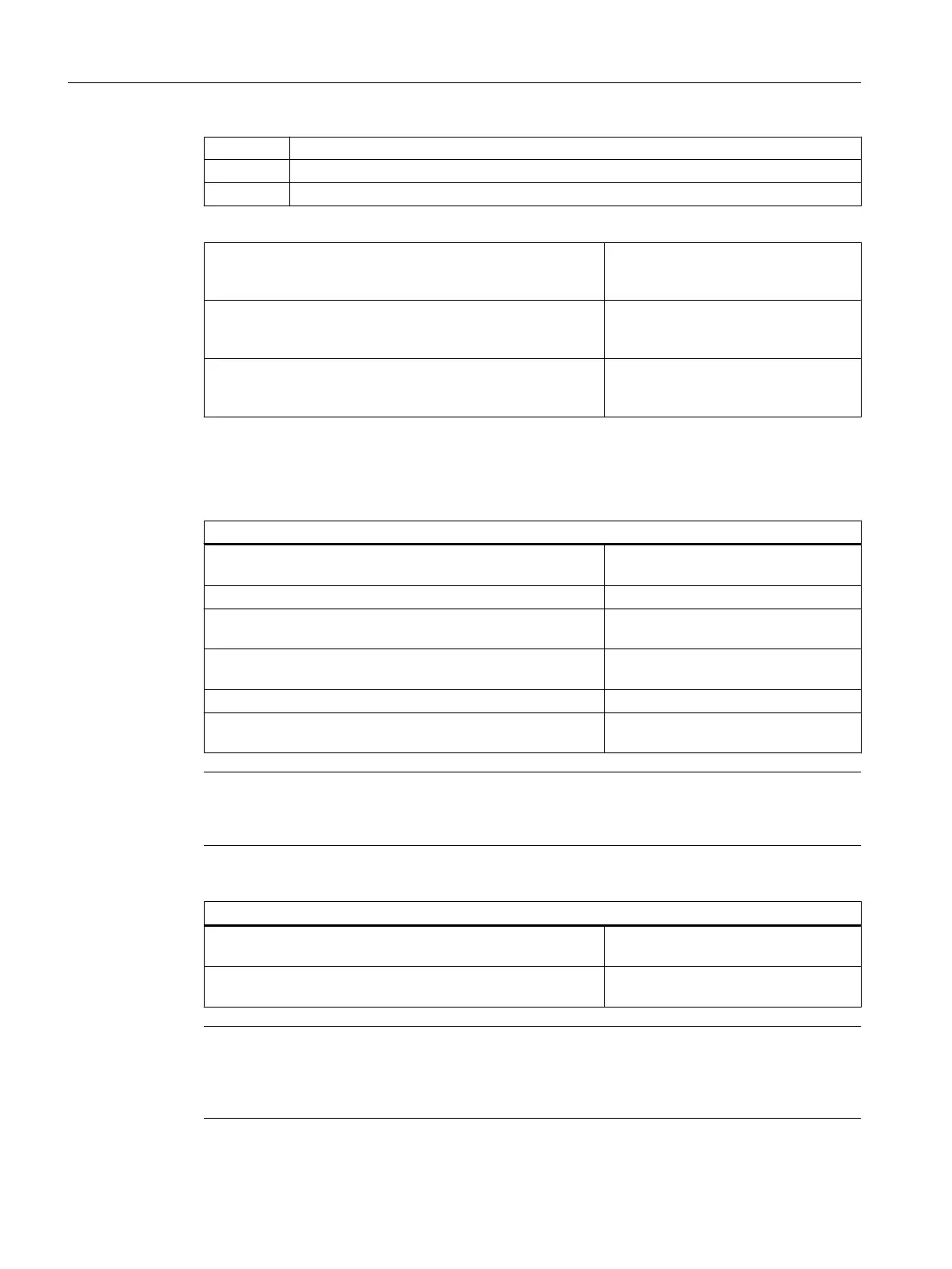

Bit 5 Enable spindle control, tool spindle

= 0 via the NC/PLC interface

= 1 via the user interface

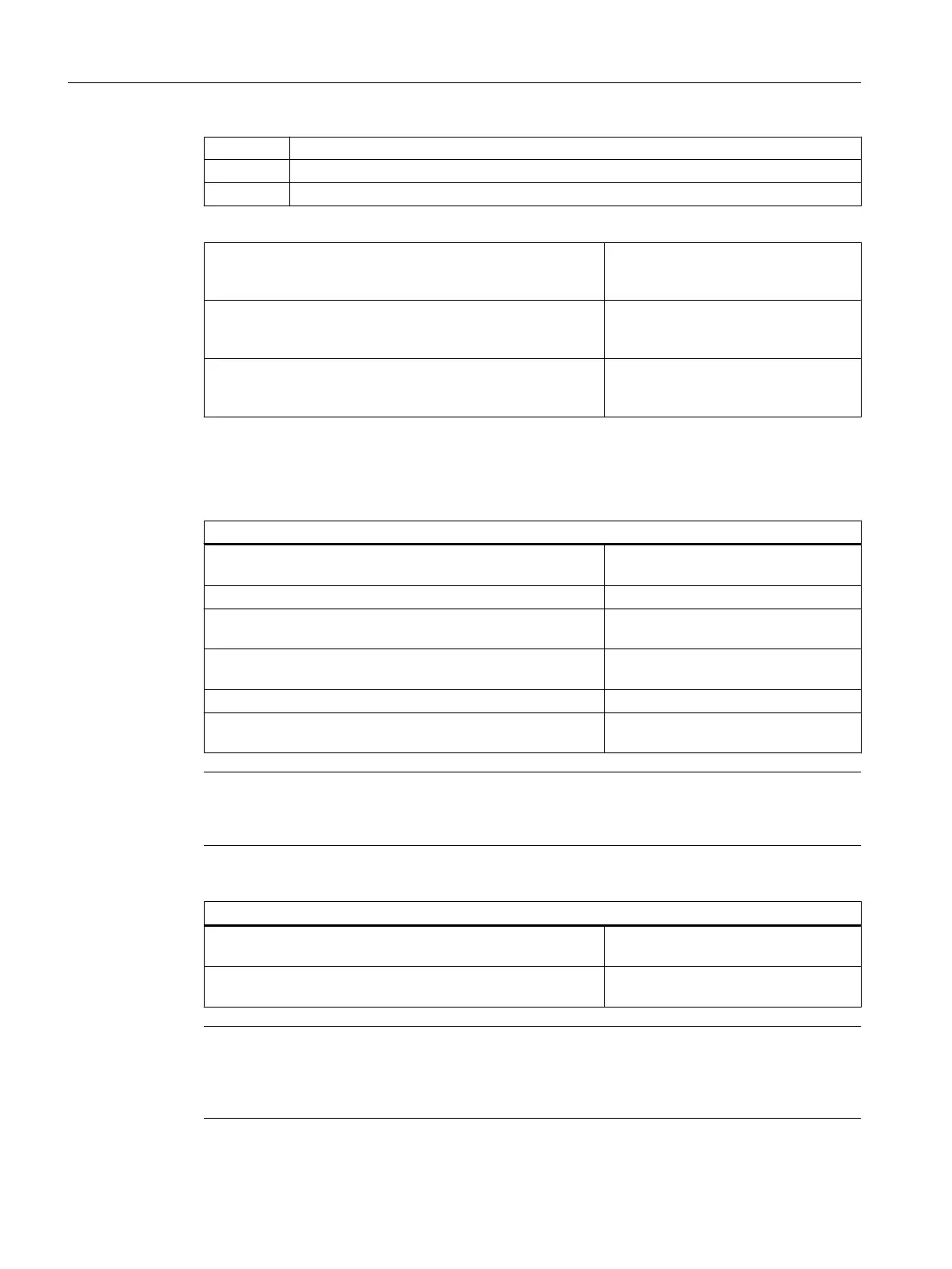

SD43200 $SA_SPIND_S Speed for spindle start using NC/PLC

interface signal; value outputs using

the operating software

SD43202 $SA_SPIND_CONSTCUT_S Cutting speed for spindle start using

NC/PLC interface signal; value outputs

using the operating software

SD43206 $SA_SPIND_SPEED_TYPE Spindle speed pipe for spindle start us‐

ing NC/PLC interface signal; value out‐

puts using the operating software

Additional parameter assignments

We recommend the following additional parameter assignments:

Handwheel

MD11346 $MN_HANDWH_TRUE_DISTANCE = 3 Handwheel path or velocity specifica‐

tion

MD11602 $MN_ASUP_START_MASK bit 0, 3 =1 Ignore stop conditions for ASUB

MD20150 $MC_G_CODE_RESET_VALUE [7] = 2 Delete position of the G groups; run-up

G54 active

MD20624 $MC_HANDWH_CHAN_STOP_COND = 0xFFFF Definition of the behavior of traveling

with handwheel, channel-specific

MD32084 HANDWH_STOP_COND = 0x7FF Behavior, handwheel travel

MD52212 FUNCTION_MASK_TECH Bit 9 = 1 Function screen form across technolo‐

gies; work offset via softkey

Note

If, in machine data MD52212 FUNCTION_MASK_TECH bit 9 is set, the "WO selection" softkey

is displayed in the "Work Offset – G54 … G599" window.

Working area limits

MD28600 $MC_MM_NUM_WORKAREA_CS_GROUPS > 0 Number of coordinate system-specific

working area limits

MD20150 $MC_GCODE_RESET_VALUES[59] = 2 Delete position of the G groups; acti‐

vate working area limits of the group

Note

If $MC_GCODE_RESET_VALUES[59] = 2 is set in the MD20150 machine data, the "Limit

stops" softkey is displayed in the "Manual Machine" window. This requires that

$MC_MM_NUM_WORKAREA_CS_GROUPS also has the value 1 for MD28600.

Customizing the "Machine" operating area

8.10 Manual machine

SINUMERIK Operate (IM9)

130 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...