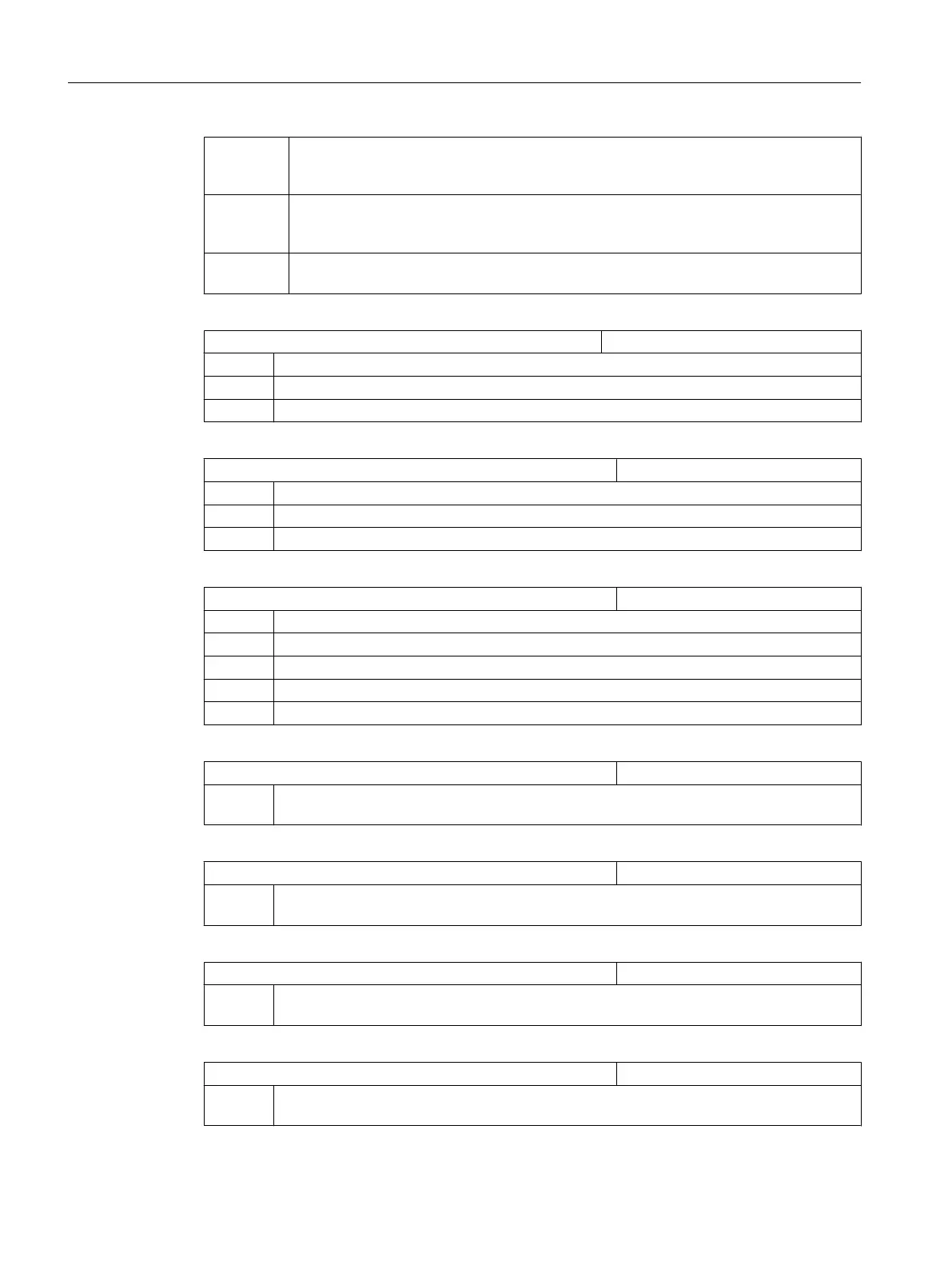

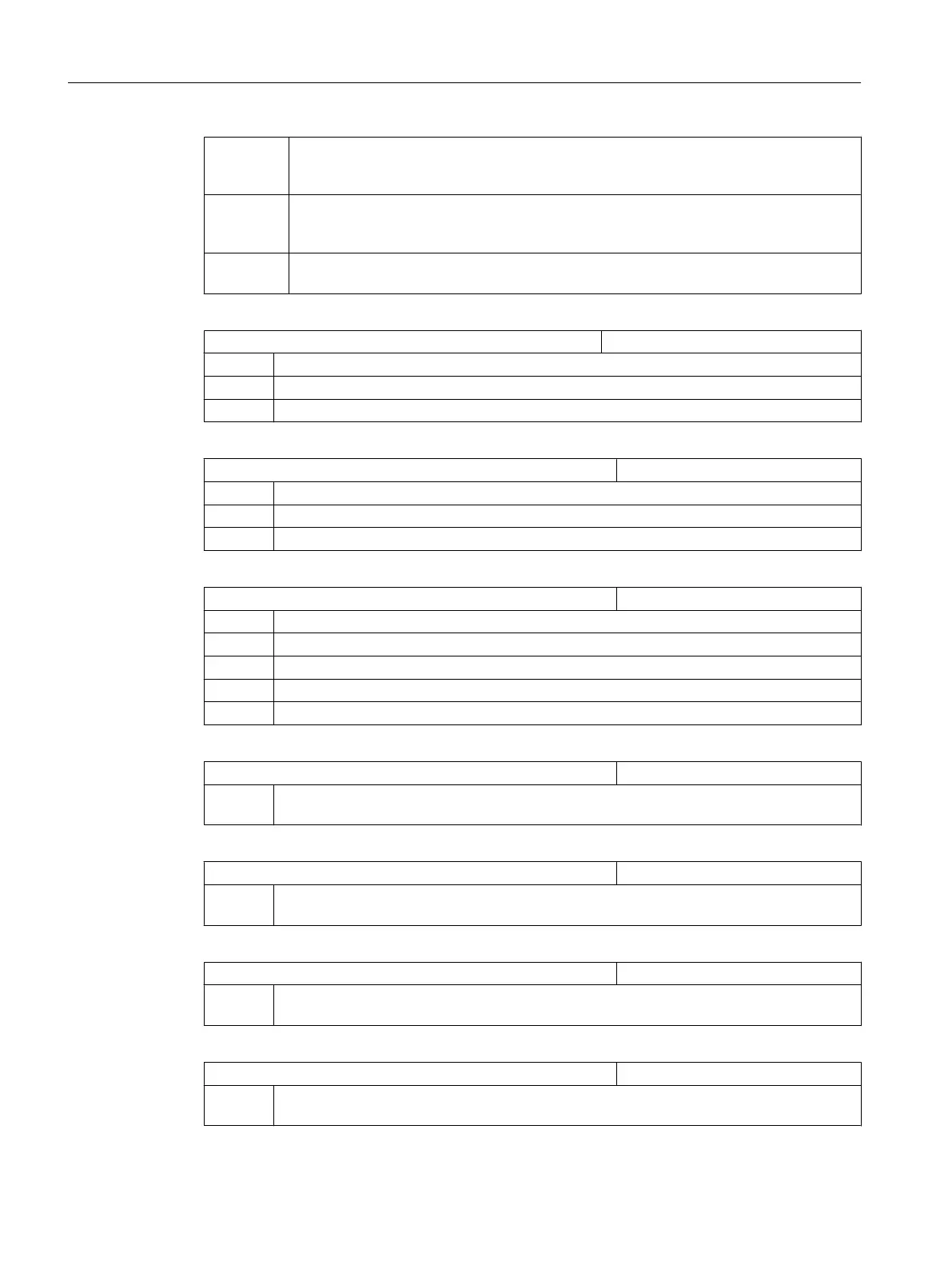

Bit 4 If you have implemented the "Clamp/release spindle" function using the manufacturer

cycle CUST_TECHCYC.SPF, then using this machine data, you can activate the "Clamp/

release spindle" parameter in the drilling and milling screens.

= 0 The "Clamp/release spindle" parameter is not displayed in the drilling and milling screens.

ShopTurn automatically clamps the spindle if it makes sense for the particular machining

operation.

= 1 The "Clamp/release spindle" parameter is displayed in the drilling and milling screens.

You decide for which machining operation the spindle should be clamped.

MD52216 $MCS_FUNCTION_MASK_DRILL Drilling function screen

Bit 3 Constant cutting speed referred to the diameter of the centering

= 0 Constant cutting speed referred to the diameter of the tool

= 1 Constant cutting speed referred to the diameter of the centering

MD52218 $MCS_FUNCTION_MASK_TURN Turning function screen

Bit 2 Enable tailstock

Bit 5 Enable spindle control of the tool spindle via user interface

Bit 6 Enable Balance Cutting for two-channel stock removal

MD52229 $MCS_ENABLE_QUICK_M_CODES Enable fast M commands

= 0

Bit 0 Coolant OFF

Bit 1 Coolant 1 ON

Bit 2 Coolant 2 ON

Bit 3 Coolants 1 and 2 ON

MD52230 $MCS_M_CODE_ALL_COOLANTS_OFF M code for all coolants off

= 9 This machine data is used to define the M function for switching off the coolant; which is

output when the tool is changed.

MD52231 $MCS_M_CODE_COOLANT_1_ON M code for coolant 1 on

= 8 This machine data is used to define the M function for coolant 1, which is output when the

tool is changed.

MD52232 $MCS_M_CODE_COOLANT_2_ON M code for coolant 2 on

= 7 This machine data is used to define the M function for coolant 2, which is output when the

tool is changed.

MD52233 $MCS_M_CODE_COOLANT_1_AND_2_ON M code for both coolants on

= -1 This machine data is used to define the M function for coolant 1 and 2, which is output when

the tool is changed.

Technologies and cycles

21.5 Turning

SINUMERIK Operate (IM9)

534 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...