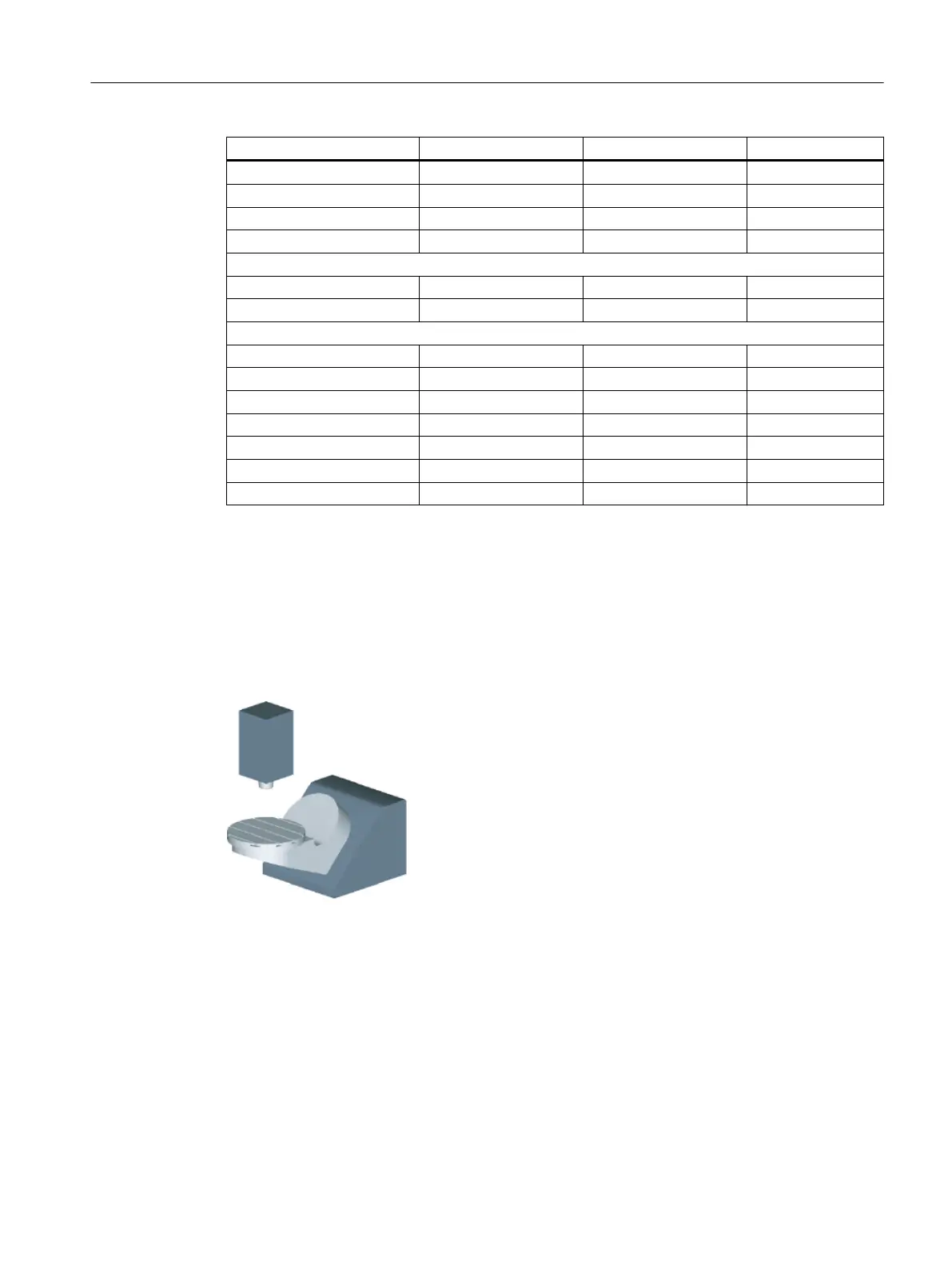

Kinematics Swivel head HEAD_2

Rotary axis vector V1 0.000 1.000 0.000

Offset vector I2 0.000 172.000 172.000

Rotary axis vector V2 0.000 1.000

1)

1.000

1)

Offset vector I3 0.000 0.000 93.800

Display version

Swivel mode Axis-by-axis

Direction reference Rotary axis 2

Rotary axes

Rotary axis 1 B Mode Manual

Angular range 0.000 360.000

Kinematics offset 0.000

Hirth joint Yes Angular grid 1.000

Rotary axis 2 C Mode Manual

Angular range 0.000 180.000

Kinematics offset 0.000

1) Calculation of rotary axis vector:

V2: 45 degree angle

V2Y = sin(-45) = -0.7071

V2Z = cos(-45) = 0.7071

V2Y and V1Z can be normalized to 1.

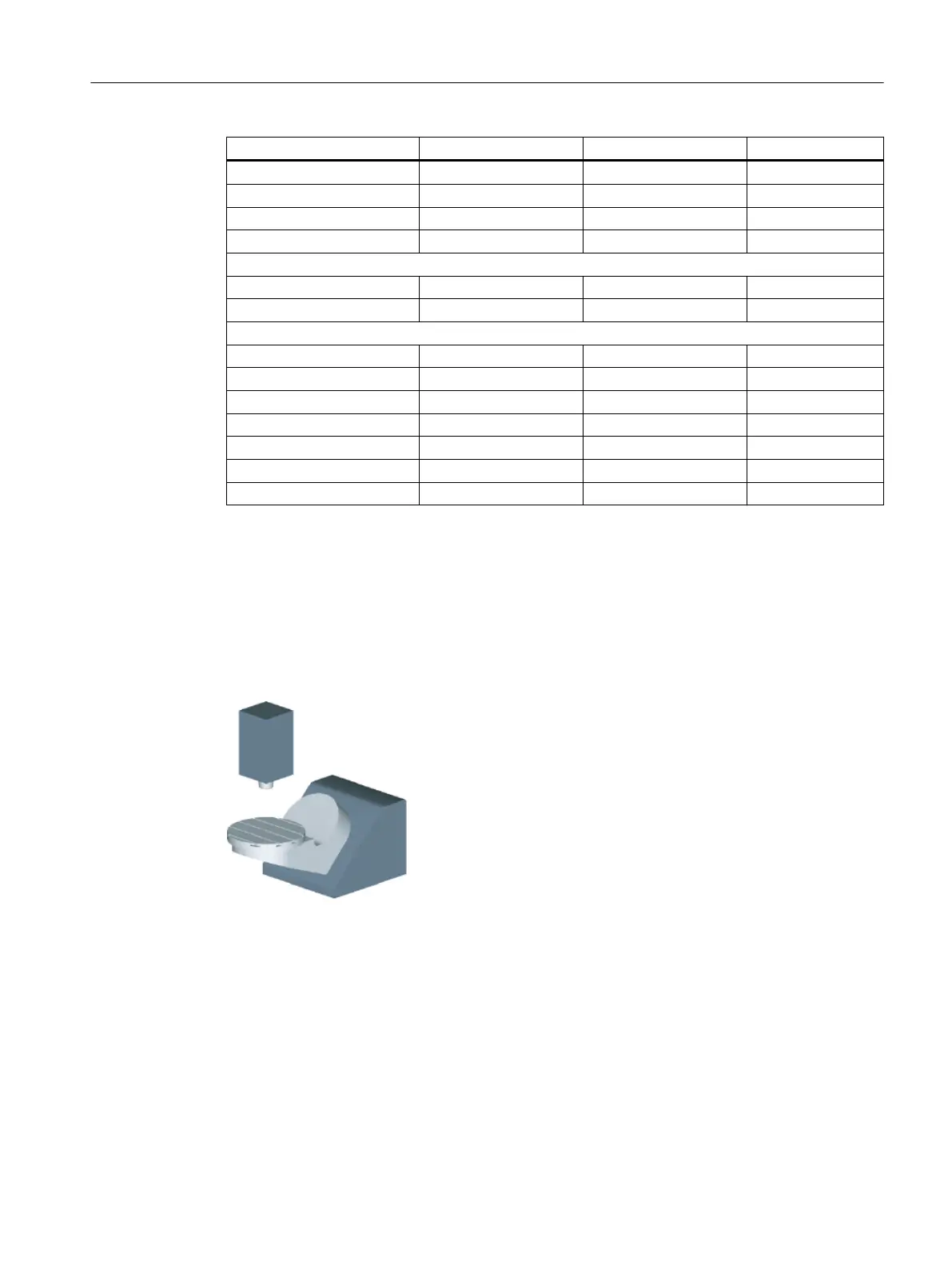

Example 3: Cardanic table "TABLE_45"

The vectors in the drawing refer to the initial setting of the kinematics. The spindle (tool adapter)

is positioned on a gage block above the top edge of the table/center of the table (rotary axis

C). A test mandrel in the spindle is used to determine the center of rotation of rotary axis C.

Technologies and cycles

21.7 Swiveling

SINUMERIK Operate (IM9)

Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1 581

Loading...

Loading...