There are 2 options available for this:

1. Direct entry of the orientation tolerance OTOL

Machining types: _ORI_ROUGH, _ORI_SEMIFIN, _ORI_FINISH

To enter the orientation tolerance in the input screen for CYCLE832, bit 1 =1 must be set

in the

setting data SD55220 $SCS_FUNCTION_MASK_MILL_TOL_SET

2. Tolerance is transferred with a factor on the NC command OTOL

Machining types: _ROUGH, _SEMIFIN, _FINISH

This factor can be set in the following channel-specific setting data for each machining type:

SD55441 $SCS_MILL_TOL_FACTOR_ROUGH Factor, tolerance of the rotary axes for rough‐

ing of the G group 59.

SD55442 $SCS_MILL_TOL_FACTOR_SEMIFIN Factor, tolerance of the rotary axes for rough‐

ing-finishing of the G group 59.

SD55443 $SCS_MILL_TOL_FACTOR_FINISH Factor, tolerance of the rotary axes for finish‐

ing of the G group 59.

= 10

For machines for which the orientation tolerance is not significant, the cycle setting data

SD55441 to 55443 can be set to a value of 0. No orientation tolerance is then calculated in

CYCLE832 (OTOL= -1).

Machining type and technology G group 59

The machining types of the technology G group 59 are permanently assigned in CYCLE832

or in CUST_832.SPF:

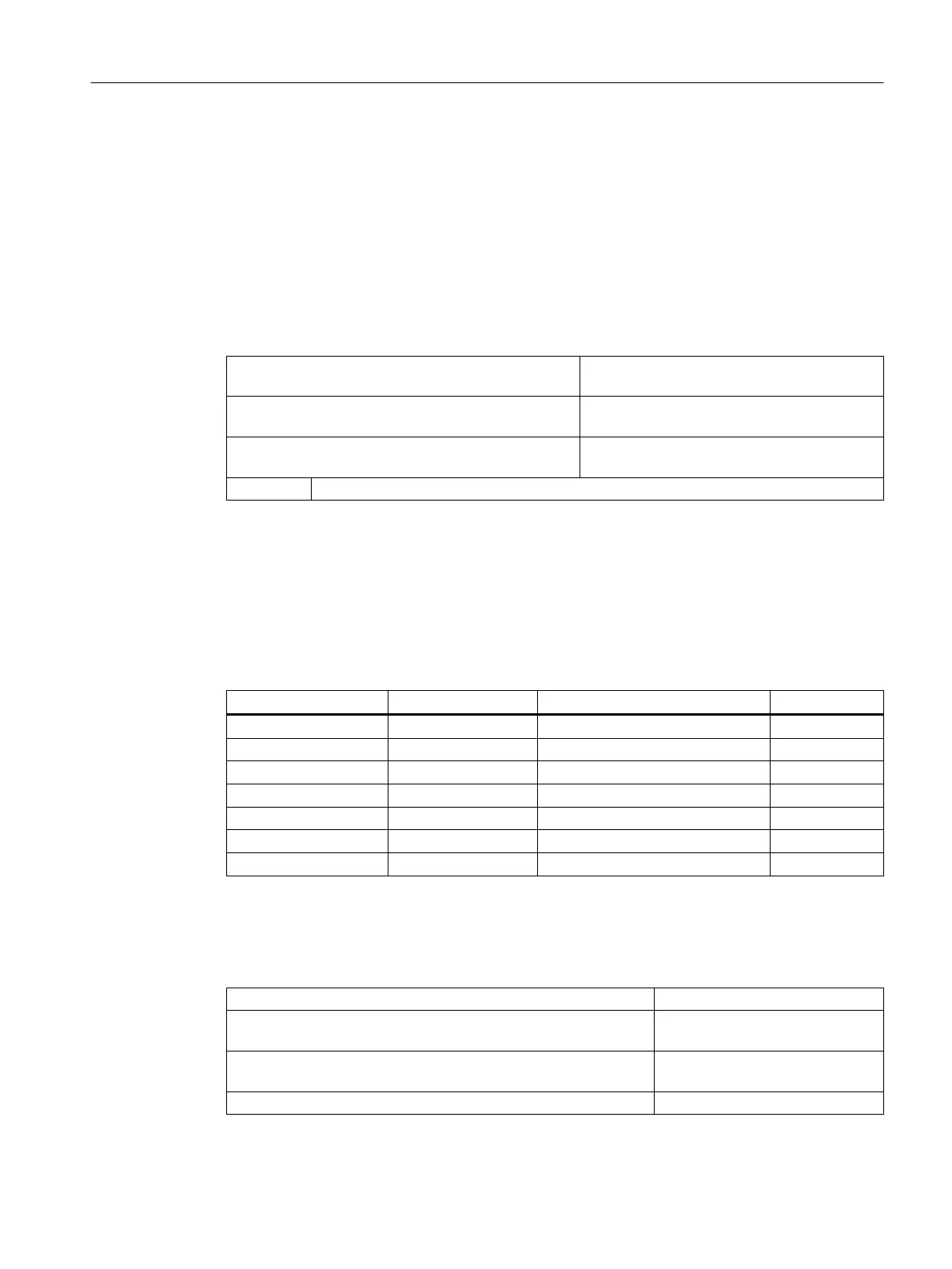

Machining type Plain text Technology G group 59 Field index

Deselection _OFF DYNNORM 0

Roughing _ROUGH DYNROUGH 2

Rough-finishing _SEMIFIN DYNSEMIFIN 3

Finishing _FINISH DYNFINISH 4

Roughing

*)

_ORI_ROUGH DYNROUGH 2

Semi-finishing

*)

_ORI_SEMIFIN DYNSEMIFIN 3

Finishing

*)

_ORI_FINISH DYNFINISH 4

*)

With entry of an orientation tolerance

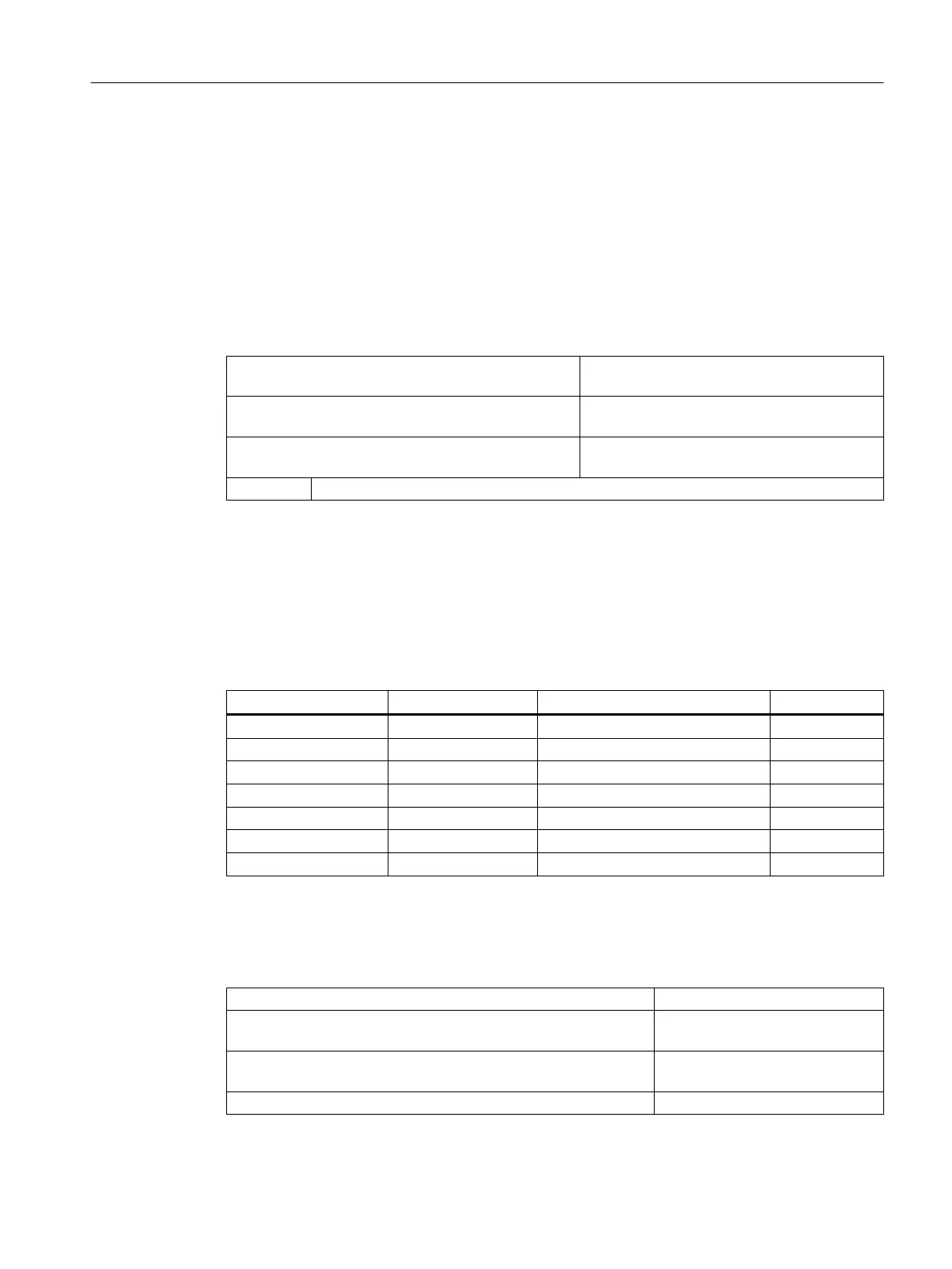

Dynamic parameters can be adapted to the respective machining operation with the

technology G groups. Using the commands of technology G group 59, the value of the following

channel and axis-specific machine data is activated using the corresponding array index:

MD20600 $MC_MAX_PATH_JERK[0..4] Path dependent maximum jerk.

MD20602 $MC_CURV_EFFECT_ON_PATH_ACCEL[0..4] Influence of path curvature on path

dynamic response.

MD20603 $MC_CURV_EFFECT_ON_PATH_JERK[0..4] Influence of path curvature on path

jerk.

MD32300 $MA_MAX_AX_ACCEL[0..4] Maximum axis acceleration.

Technologies and cycles

21.9 High-speed machining

SINUMERIK Operate (IM9)

Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1 613

Loading...

Loading...