Requirement

You have already made the settings from the following section:

See also: Measuring cycles and measurement functions, general (Page 617)

Settings

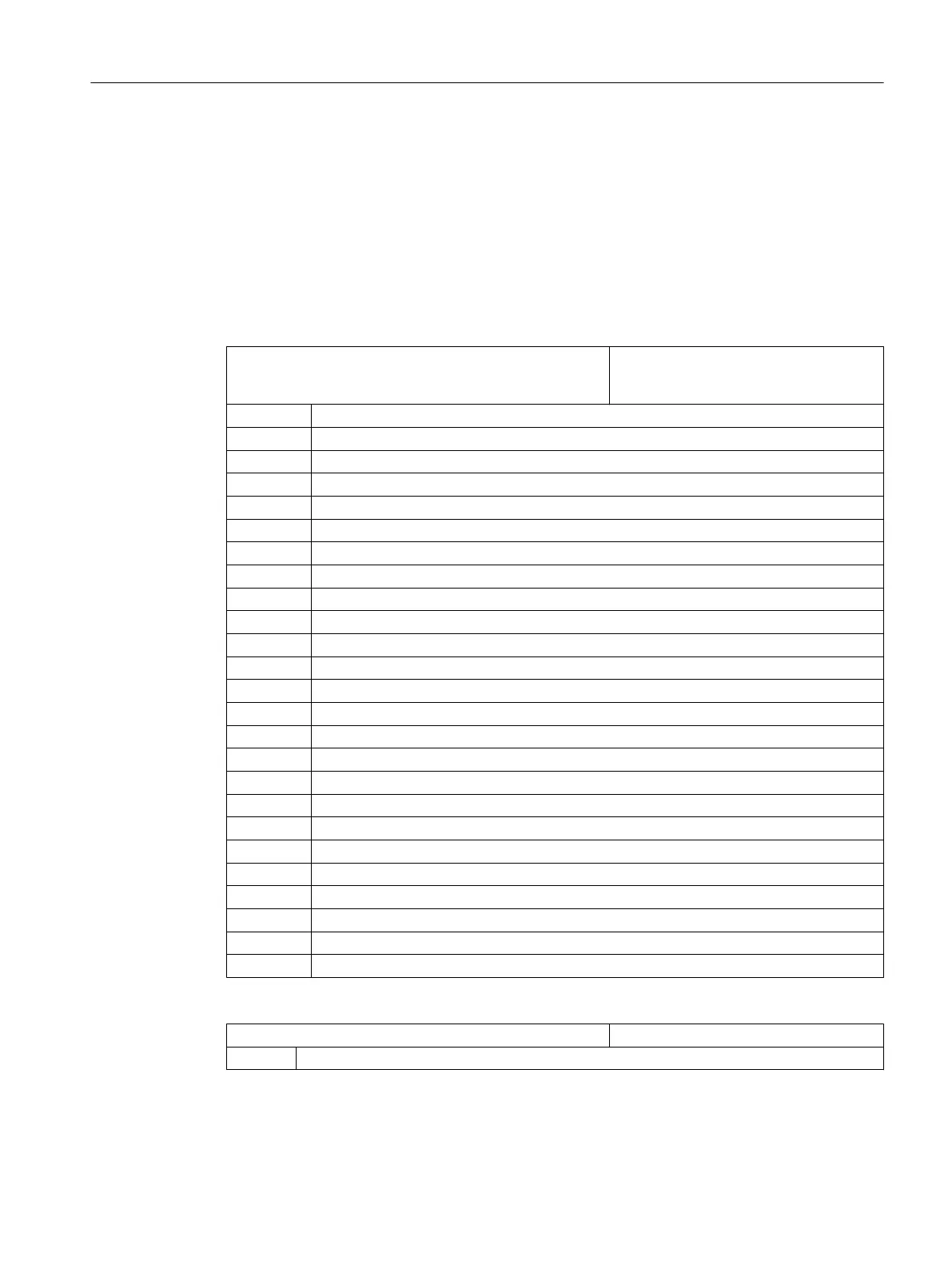

General cycle setting data

SD54760 $SNS_MEA_FUNCTION_MASK_PIECE Settings for the input screen, measuring

cycles in AUTOMATIC, workpiece meas‐

urement.

Bit 1 Display select softkey 3D measurement

Bit 3 Enable probe calibration field to be selected

Bit 4 Select calibration input measuring feed

1)

Bit 6 Enable NP correction in the basis reference (SETFRAME) to be selected

Bit 7 Enable NP correction in channel-specific basic frame to be selected

Bit 8 Enable NP correction in global basic frame to be selected

Bit 9 Enable NP correction in adjustable frame to be selected

Bit 10 Enable NP correction coarse and fine to be selected

Bit 11 Select tool offset, geometry and wear

Bit 12 Select tool offset, not inverted and inverted

Bit 13 Select tool offset L1, R or L1, L2, L3 R

Bit 14 Select tool offset, zero offset (_TZL)

Bit 15 Select tool offset, dimensional difference monitoring (_TDIF)

Bit 16 Select workpiece measurement with spindle reversal

Bit 17 Selects align workpiece probe in the switching direction

Bit 18 Select number of measurements (_NMSP)

Bit 19 Select offset with mean value generation (_TMV)

1)

Bit 20 Select experience values (_EVNUM)

Bit 21 Select total setting-up offset

Bit 22 Select calibration to unknown or to known center point

Bit 24 Select calibration with/without position deviation

Bit 25 Select zero offset when measuring the angulation of the spindle

Bit 26 Selects tool offset, do not enable

Bit 27 Selects measure tolerance of the linear vector for kinematics, do not enable

Bit 28 Enable tool offset adjust length to be selected

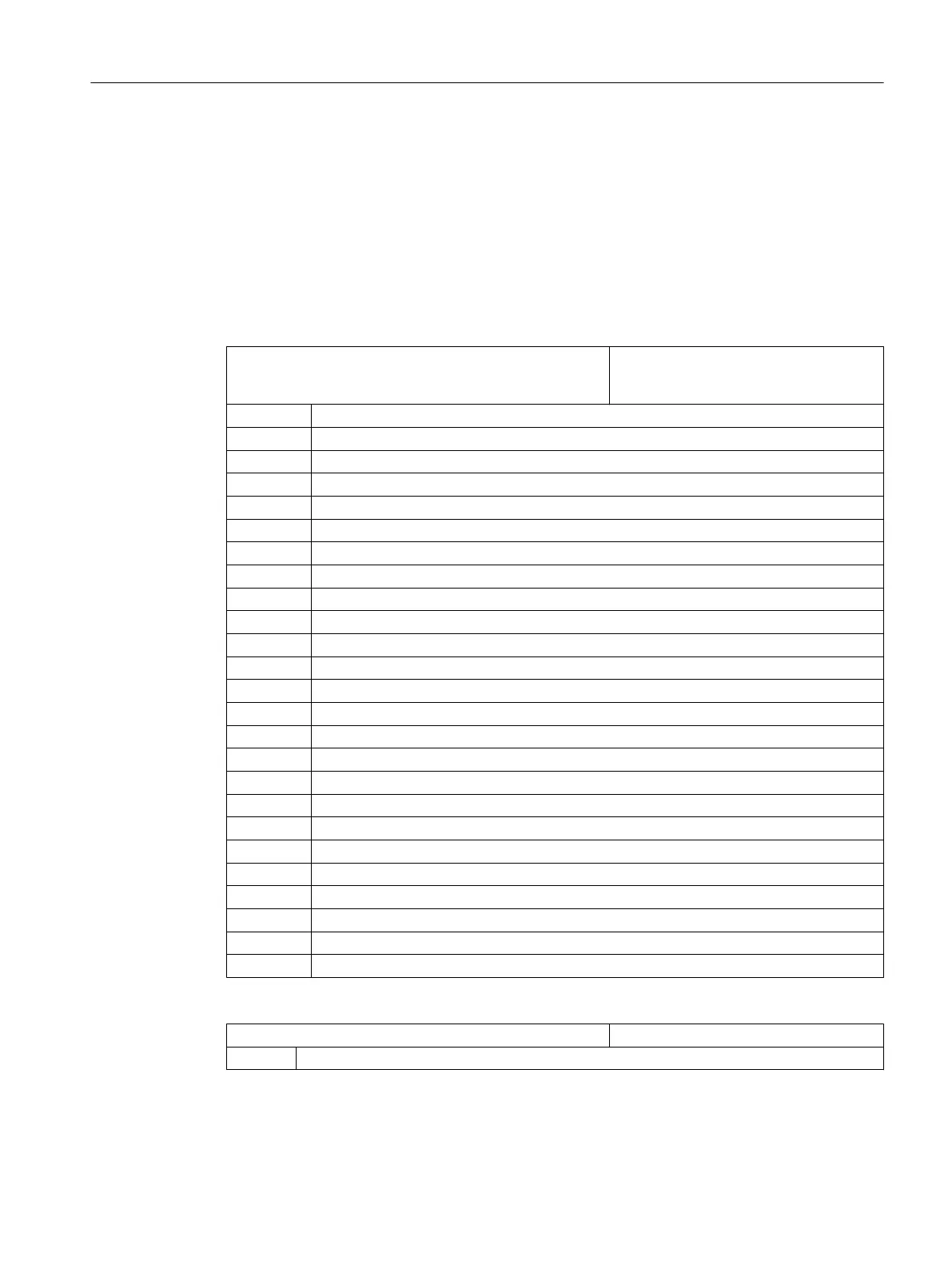

Channel-specific cycle setting data

SD55630 $SCS_MEA_FEED_MEASURE Measuring feedrate [mm/rev]

= 300 Measuring feedrate when calibrating the workpiece probe

Technologies and cycles

21.10 Measuring cycles and measurement functions

SINUMERIK Operate (IM9)

Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1 637

Loading...

Loading...